Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing workflows and boost operational efficiency. Smart manufacturing employs IoT, data analytics, and real-time monitoring to enhance production agility, quality, and resource management. Discover how these innovations transform industry standards and drive competitive advantage.

Why it is important

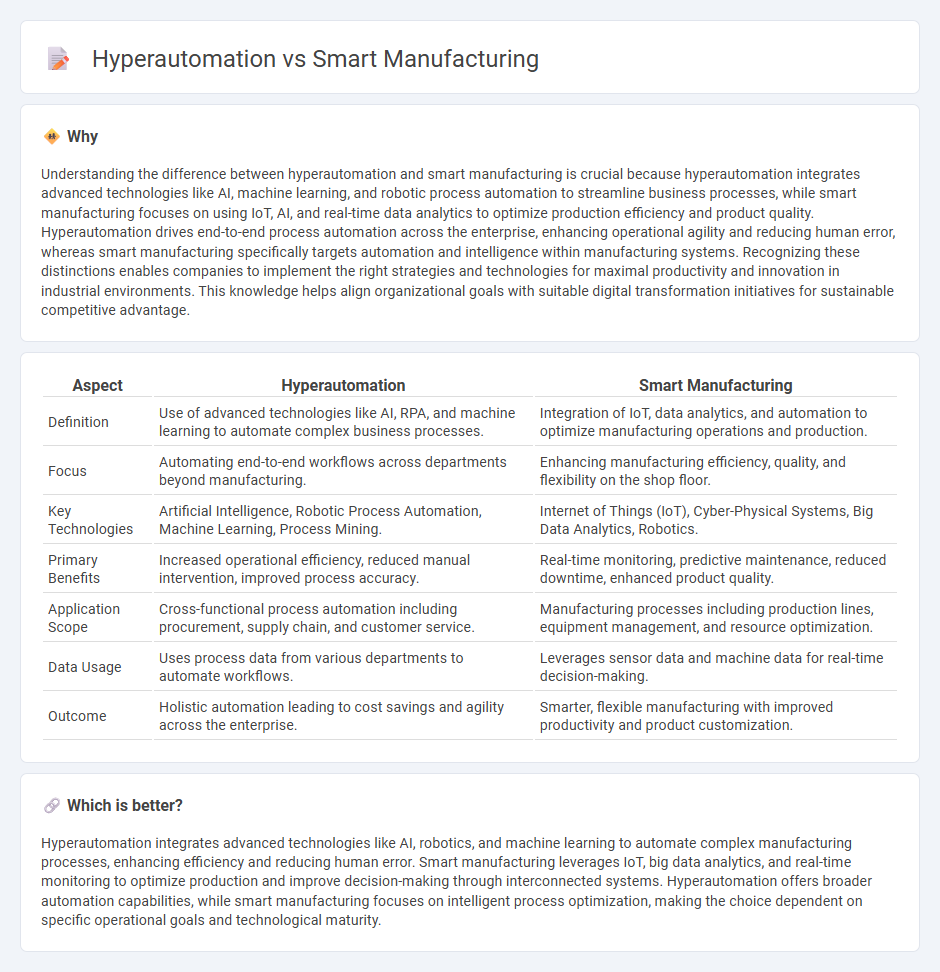

Understanding the difference between hyperautomation and smart manufacturing is crucial because hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to streamline business processes, while smart manufacturing focuses on using IoT, AI, and real-time data analytics to optimize production efficiency and product quality. Hyperautomation drives end-to-end process automation across the enterprise, enhancing operational agility and reducing human error, whereas smart manufacturing specifically targets automation and intelligence within manufacturing systems. Recognizing these distinctions enables companies to implement the right strategies and technologies for maximal productivity and innovation in industrial environments. This knowledge helps align organizational goals with suitable digital transformation initiatives for sustainable competitive advantage.

Comparison Table

| Aspect | Hyperautomation | Smart Manufacturing |

|---|---|---|

| Definition | Use of advanced technologies like AI, RPA, and machine learning to automate complex business processes. | Integration of IoT, data analytics, and automation to optimize manufacturing operations and production. |

| Focus | Automating end-to-end workflows across departments beyond manufacturing. | Enhancing manufacturing efficiency, quality, and flexibility on the shop floor. |

| Key Technologies | Artificial Intelligence, Robotic Process Automation, Machine Learning, Process Mining. | Internet of Things (IoT), Cyber-Physical Systems, Big Data Analytics, Robotics. |

| Primary Benefits | Increased operational efficiency, reduced manual intervention, improved process accuracy. | Real-time monitoring, predictive maintenance, reduced downtime, enhanced product quality. |

| Application Scope | Cross-functional process automation including procurement, supply chain, and customer service. | Manufacturing processes including production lines, equipment management, and resource optimization. |

| Data Usage | Uses process data from various departments to automate workflows. | Leverages sensor data and machine data for real-time decision-making. |

| Outcome | Holistic automation leading to cost savings and agility across the enterprise. | Smarter, flexible manufacturing with improved productivity and product customization. |

Which is better?

Hyperautomation integrates advanced technologies like AI, robotics, and machine learning to automate complex manufacturing processes, enhancing efficiency and reducing human error. Smart manufacturing leverages IoT, big data analytics, and real-time monitoring to optimize production and improve decision-making through interconnected systems. Hyperautomation offers broader automation capabilities, while smart manufacturing focuses on intelligent process optimization, making the choice dependent on specific operational goals and technological maturity.

Connection

Hyperautomation integrates advanced technologies like AI, IoT, and robotics to optimize processes in smart manufacturing, enabling real-time data analysis and autonomous decision-making. Smart manufacturing leverages this automation to enhance production efficiency, reduce downtime, and improve product quality through interconnected systems. Together, they create a seamless, adaptive manufacturing environment that drives innovation and operational excellence.

Key Terms

IoT (Internet of Things)

Smart manufacturing integrates IoT devices to enable real-time data collection and process optimization, driving operational efficiency and predictive maintenance. Hyperautomation leverages IoT alongside AI and machine learning to automate complex tasks, enhance decision-making, and create adaptive manufacturing systems. Discover how combining smart manufacturing with hyperautomation transforms industrial IoT applications.

AI/ML (Artificial Intelligence/Machine Learning)

Smart manufacturing leverages AI/ML to optimize production processes, improve quality control, and predict maintenance needs through data-driven insights and automation of specific tasks. Hyperautomation expands beyond traditional automation by integrating AI/ML with robotic process automation (RPA), advanced analytics, and intelligent decision-making to automate complex end-to-end workflows across manufacturing operations. Explore the latest advancements in AI-powered smart manufacturing and hyperautomation to transform industrial efficiency and innovation.

RPA (Robotic Process Automation)

Smart manufacturing integrates IoT, AI, and robotics to optimize production processes, emphasizing physical automation on the shop floor, while hyperautomation leverages RPA to automate complex business workflows across IT and administrative functions. RPA in hyperautomation streamlines repetitive tasks by mimicking human actions on digital systems, accelerating operational efficiency and reducing errors beyond traditional manufacturing environments. Explore how RPA drives hyperautomation to transform enterprise operations and enhance productivity at scale.

Source and External Links

What Is Smart Manufacturing? | Oracle - Smart manufacturing integrates modern data science and artificial intelligence to create highly connected, knowledge-enabled industrial enterprises that improve efficiency, productivity, and sustainability by enabling real-time data use and open infrastructure solutions.

What Is Smart Manufacturing? - CESMII - Smart manufacturing orchestrates business, physical, and digital processes with integrated sensing, predictive analytics, and workflow automation to improve speed, agility, quality, asset reliability, and profitability.

Smart manufacturing - Wikipedia - Smart manufacturing involves computer-integrated manufacturing and automation to increase adaptability, eliminate inefficiencies, enhance worker safety, and optimize performance by using intelligent systems and AI-driven automation.

dowidth.com

dowidth.com