Adaptive machining leverages real-time data and advanced sensors to dynamically adjust cutting parameters, enhancing precision and reducing material waste. Batch production focuses on manufacturing fixed quantities of products, optimizing for cost efficiency and consistency across identical units. Explore how these manufacturing methods can boost productivity and product quality in diverse industrial settings.

Why it is important

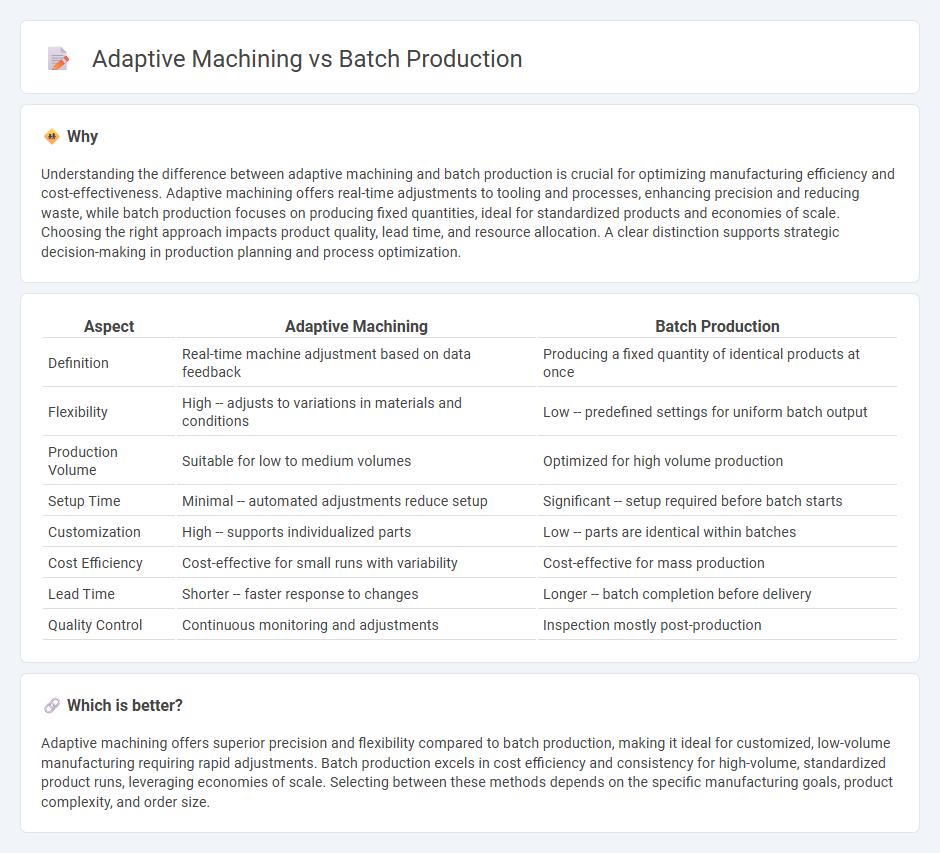

Understanding the difference between adaptive machining and batch production is crucial for optimizing manufacturing efficiency and cost-effectiveness. Adaptive machining offers real-time adjustments to tooling and processes, enhancing precision and reducing waste, while batch production focuses on producing fixed quantities, ideal for standardized products and economies of scale. Choosing the right approach impacts product quality, lead time, and resource allocation. A clear distinction supports strategic decision-making in production planning and process optimization.

Comparison Table

| Aspect | Adaptive Machining | Batch Production |

|---|---|---|

| Definition | Real-time machine adjustment based on data feedback | Producing a fixed quantity of identical products at once |

| Flexibility | High -- adjusts to variations in materials and conditions | Low -- predefined settings for uniform batch output |

| Production Volume | Suitable for low to medium volumes | Optimized for high volume production |

| Setup Time | Minimal -- automated adjustments reduce setup | Significant -- setup required before batch starts |

| Customization | High -- supports individualized parts | Low -- parts are identical within batches |

| Cost Efficiency | Cost-effective for small runs with variability | Cost-effective for mass production |

| Lead Time | Shorter -- faster response to changes | Longer -- batch completion before delivery |

| Quality Control | Continuous monitoring and adjustments | Inspection mostly post-production |

Which is better?

Adaptive machining offers superior precision and flexibility compared to batch production, making it ideal for customized, low-volume manufacturing requiring rapid adjustments. Batch production excels in cost efficiency and consistency for high-volume, standardized product runs, leveraging economies of scale. Selecting between these methods depends on the specific manufacturing goals, product complexity, and order size.

Connection

Adaptive machining enhances batch production by enabling real-time adjustments to tooling parameters, which improves precision and reduces material waste. This integration allows manufacturers to maintain consistent product quality across large production runs while accommodating slight variations in raw materials or machine conditions. Implementing adaptive machining within batch production systems drives efficiency, lowers costs, and supports scalable manufacturing processes.

Key Terms

Production Flexibility

Batch production offers limited production flexibility due to its fixed processing steps and set batch sizes, making it efficient for high-volume, uniform products. Adaptive machining enhances production flexibility by utilizing real-time process adjustments and machine learning, allowing for customization and variability in small or complex runs. Explore how adaptive machining transforms manufacturing adaptability for your specific production demands.

Customization

Batch production involves manufacturing large quantities of identical products, limiting customization options due to standardized processes and tooling. Adaptive machining enables high customization by dynamically adjusting parameters and tooling in real-time, catering to unique specifications and small batch runs. Explore how adaptive machining revolutionizes customization and meets diverse production needs efficiently.

Process Automation

Batch production automates repetitive manufacturing tasks by processing large quantities of identical products, increasing efficiency and reducing labor costs. Adaptive machining leverages real-time data and machine learning to adjust operations dynamically, optimizing precision and minimizing material waste. Explore how integrating these automation strategies can transform your manufacturing process.

Source and External Links

What is batch production in manufacturing? - OneAdvanced - Batch production is a method where a group of identical products are made at the same time, with each batch moving together through all production stages, allowing for flexibility and quality checks between batches.

Batch Production - Benefits, Examples, and Tips - MRPeasy - In batch production, sets of identical goods go through each production stage together, enabling manufacturers to create product variants and maintain quality control, though it can lead to high work-in-progress inventory and idle time between batches.

Batch Production: Examples, Advantages and Disadvantages - Batch production involves producing groups of identical items simultaneously, with each batch completing one stage before the next begins, offering flexibility and easier quality management but potentially causing downtime between batches.

dowidth.com

dowidth.com