Digital twinning creates a virtual replica of physical assets to monitor, simulate, and optimize manufacturing processes in real-time, enhancing operational efficiency and predictive maintenance. Additive manufacturing, or 3D printing, builds components layer-by-layer directly from digital models, enabling complex designs and rapid prototyping with reduced material waste. Explore how integrating digital twinning with additive manufacturing can revolutionize production workflows and boost innovation.

Why it is important

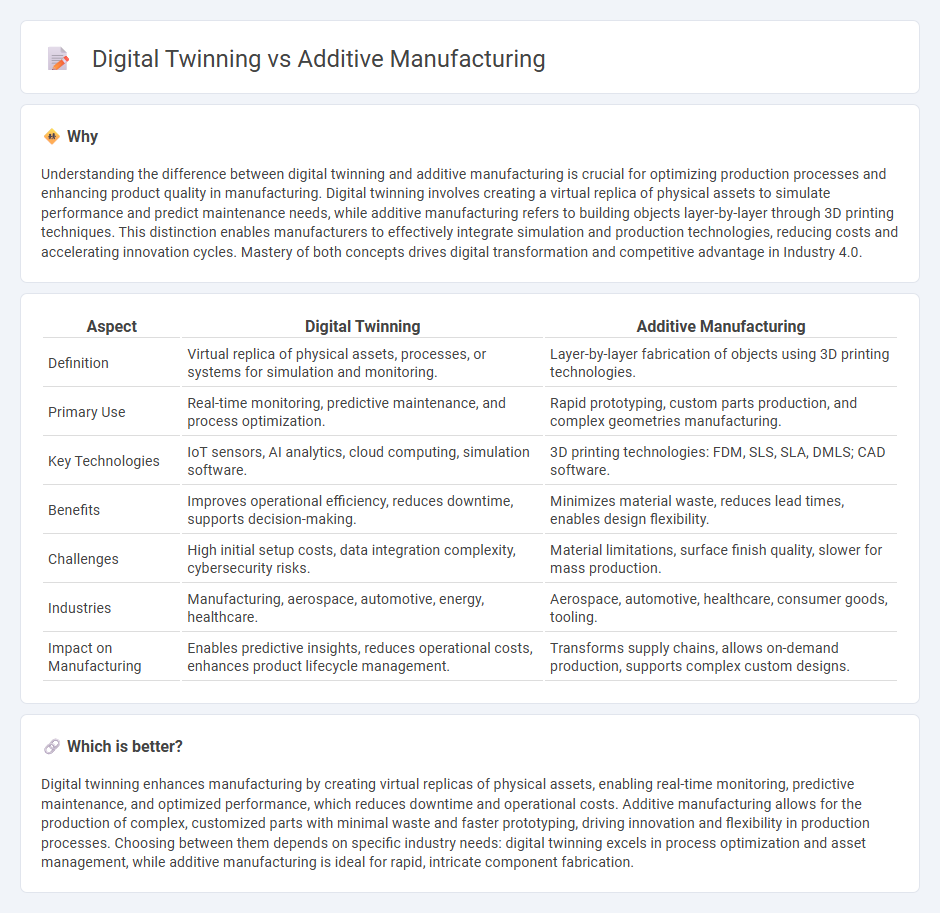

Understanding the difference between digital twinning and additive manufacturing is crucial for optimizing production processes and enhancing product quality in manufacturing. Digital twinning involves creating a virtual replica of physical assets to simulate performance and predict maintenance needs, while additive manufacturing refers to building objects layer-by-layer through 3D printing techniques. This distinction enables manufacturers to effectively integrate simulation and production technologies, reducing costs and accelerating innovation cycles. Mastery of both concepts drives digital transformation and competitive advantage in Industry 4.0.

Comparison Table

| Aspect | Digital Twinning | Additive Manufacturing |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems for simulation and monitoring. | Layer-by-layer fabrication of objects using 3D printing technologies. |

| Primary Use | Real-time monitoring, predictive maintenance, and process optimization. | Rapid prototyping, custom parts production, and complex geometries manufacturing. |

| Key Technologies | IoT sensors, AI analytics, cloud computing, simulation software. | 3D printing technologies: FDM, SLS, SLA, DMLS; CAD software. |

| Benefits | Improves operational efficiency, reduces downtime, supports decision-making. | Minimizes material waste, reduces lead times, enables design flexibility. |

| Challenges | High initial setup costs, data integration complexity, cybersecurity risks. | Material limitations, surface finish quality, slower for mass production. |

| Industries | Manufacturing, aerospace, automotive, energy, healthcare. | Aerospace, automotive, healthcare, consumer goods, tooling. |

| Impact on Manufacturing | Enables predictive insights, reduces operational costs, enhances product lifecycle management. | Transforms supply chains, allows on-demand production, supports complex custom designs. |

Which is better?

Digital twinning enhances manufacturing by creating virtual replicas of physical assets, enabling real-time monitoring, predictive maintenance, and optimized performance, which reduces downtime and operational costs. Additive manufacturing allows for the production of complex, customized parts with minimal waste and faster prototyping, driving innovation and flexibility in production processes. Choosing between them depends on specific industry needs: digital twinning excels in process optimization and asset management, while additive manufacturing is ideal for rapid, intricate component fabrication.

Connection

Digital twinning enhances additive manufacturing by creating virtual replicas of physical products and manufacturing processes, enabling real-time simulation and optimization. This connection allows for precise control over 3D printing parameters, reducing material waste and accelerating prototyping cycles. Integrating these technologies improves product quality, minimizes production errors, and streamlines the entire manufacturing workflow.

Key Terms

3D Printing

Additive manufacturing, commonly known as 3D printing, builds physical objects layer by layer from digital models, enabling rapid prototyping and complex geometries in aerospace, healthcare, and automotive industries. Digital twinning creates a virtual replica of physical assets to simulate, monitor, and optimize performance in real-time, enhancing predictive maintenance and operational efficiency across manufacturing processes. Explore how integrating additive manufacturing with digital twinning transforms product development and industrial innovation in greater detail.

Virtual Simulation

Additive manufacturing enables precise layer-by-layer creation of complex components, enhancing production flexibility and reducing material waste. Digital twinning integrates virtual simulation to replicate real-world processes, allowing for predictive analysis and optimization of manufacturing performance. Explore how combining additive manufacturing with digital twin technology revolutionizes virtual simulation in modern industry.

Data Integration

Additive manufacturing generates complex, customizable parts through layer-by-layer material deposition, producing extensive real-time production data. Digital twinning integrates this data by creating virtual replicas of physical assets, enabling continuous monitoring, simulation, and optimization. Explore how seamless data integration enhances manufacturing efficiency and innovation by connecting these advanced technologies.

Source and External Links

Additive manufacturing, explained - Additive manufacturing is the process of creating an object by building it layer by layer, typically using 3D printing, and it has evolved from rapid prototyping in the 1980s to functional product manufacturing today, utilizing materials such as polymers, metals, and biomaterials.

Additive manufacturing | NIST - Additive manufacturing uses digital designs to fabricate 3D products by laying down material layer-by-layer, enabling complex designs with less waste, and is impacting industries from aerospace to biomedical implants, with ongoing work on standards and measurement science to support its growth.

What Is Additive Manufacturing? | 3D Printing Simulation ... - Additive manufacturing builds physical models from digital 3D CAD designs through processes like powder bed fusion, material extrusion, binder jetting, photopolymerization, and direct energy deposition, serving industrial needs for prototypes and production parts.

dowidth.com

dowidth.com