Closed-loop manufacturing integrates real-time feedback systems to continuously monitor and adjust production processes, enhancing precision and reducing waste. Smart manufacturing leverages IoT, AI, and data analytics to optimize operations, improve efficiency, and enable predictive maintenance. Explore the key differences and benefits of closed-loop and smart manufacturing to elevate your production strategy.

Why it is important

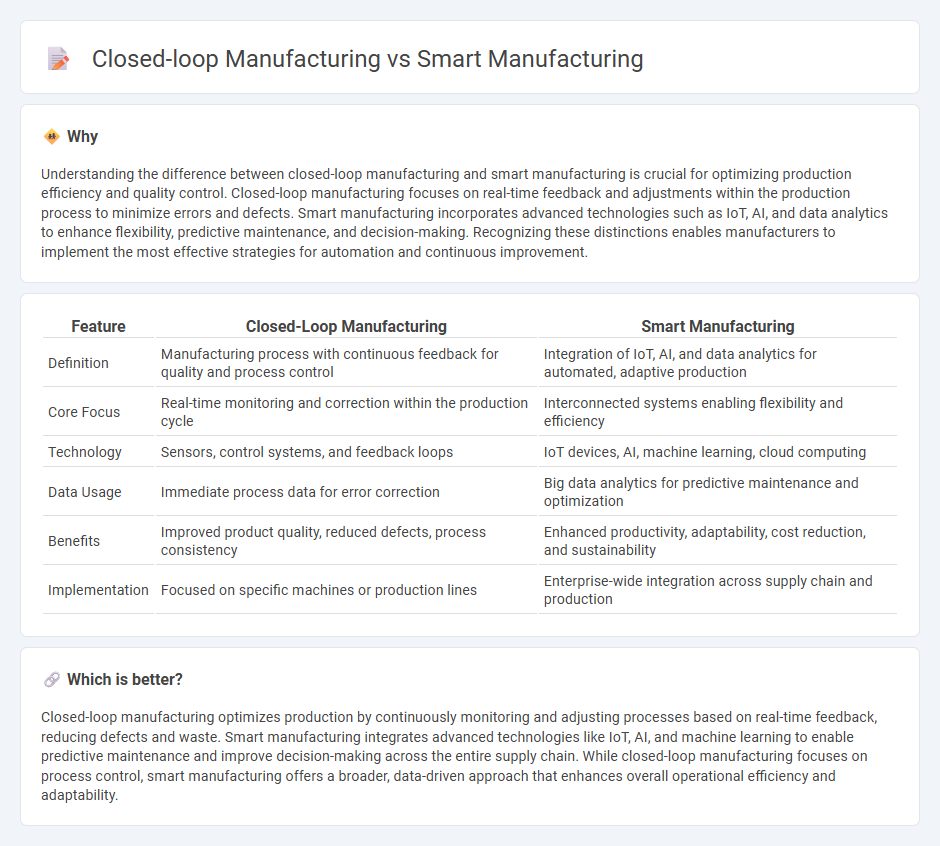

Understanding the difference between closed-loop manufacturing and smart manufacturing is crucial for optimizing production efficiency and quality control. Closed-loop manufacturing focuses on real-time feedback and adjustments within the production process to minimize errors and defects. Smart manufacturing incorporates advanced technologies such as IoT, AI, and data analytics to enhance flexibility, predictive maintenance, and decision-making. Recognizing these distinctions enables manufacturers to implement the most effective strategies for automation and continuous improvement.

Comparison Table

| Feature | Closed-Loop Manufacturing | Smart Manufacturing |

|---|---|---|

| Definition | Manufacturing process with continuous feedback for quality and process control | Integration of IoT, AI, and data analytics for automated, adaptive production |

| Core Focus | Real-time monitoring and correction within the production cycle | Interconnected systems enabling flexibility and efficiency |

| Technology | Sensors, control systems, and feedback loops | IoT devices, AI, machine learning, cloud computing |

| Data Usage | Immediate process data for error correction | Big data analytics for predictive maintenance and optimization |

| Benefits | Improved product quality, reduced defects, process consistency | Enhanced productivity, adaptability, cost reduction, and sustainability |

| Implementation | Focused on specific machines or production lines | Enterprise-wide integration across supply chain and production |

Which is better?

Closed-loop manufacturing optimizes production by continuously monitoring and adjusting processes based on real-time feedback, reducing defects and waste. Smart manufacturing integrates advanced technologies like IoT, AI, and machine learning to enable predictive maintenance and improve decision-making across the entire supply chain. While closed-loop manufacturing focuses on process control, smart manufacturing offers a broader, data-driven approach that enhances overall operational efficiency and adaptability.

Connection

Closed-loop manufacturing integrates real-time sensor data and feedback systems to continuously optimize production processes, closely aligning with smart manufacturing's emphasis on automation and data-driven decision-making. Both approaches leverage advanced technologies such as IoT, AI, and machine learning to enhance product quality, reduce waste, and improve operational efficiency. The synergy between closed-loop systems and smart manufacturing enables dynamic adjustments and predictive maintenance, driving innovation and sustainability in industrial production.

Key Terms

IoT Integration

Smart manufacturing leverages IoT integration to enable real-time data collection, predictive maintenance, and adaptive production processes, enhancing operational efficiency and reducing downtime. Closed-loop manufacturing incorporates IoT sensors and feedback systems to continuously monitor and adjust manufacturing parameters, ensuring quality control and minimizing waste throughout the production cycle. Discover how IoT-driven smart and closed-loop manufacturing can transform your industrial operations with improved connectivity and automation.

Real-time Data Analytics

Smart manufacturing leverages IoT sensors and AI algorithms to optimize production by analyzing real-time data streams, enhancing operational efficiency and predictive maintenance. Closed-loop manufacturing integrates feedback systems in real-time data analytics for continuous monitoring and adaptive control, ensuring quality and minimizing waste through immediate adjustments. Explore how both approaches transform industry processes with advanced data analytics to boost productivity and innovation.

Feedback Control Systems

Smart manufacturing leverages real-time data analytics and IoT integration to optimize production processes with enhanced flexibility and efficiency. Closed-loop manufacturing emphasizes continuous feedback control systems that monitor and adjust operations automatically to maintain quality and reduce errors. Explore deeper insights into how feedback control systems revolutionize manufacturing performance and reliability.

Source and External Links

What Is Smart Manufacturing? - Smart manufacturing is the convergence of data science and artificial intelligence with industrial processes to create highly connected, knowledge-enabled, and efficient operations that enhance productivity, sustainability, and economic performance across the supply chain.

What Is Smart Manufacturing? - Information-driven and collaborative, smart manufacturing integrates, monitors, and continuously evaluates resources and processes using digital technologies to automate routine actions, predict problems, and orchestrate improvements in speed, quality, cost, safety, and asset reliability.

Smart manufacturing - Wikipedia - Employing computer-integrated manufacturing and advanced automation, smart manufacturing focuses on adaptability, rapid design changes, and real-time data analysis to eliminate workplace inefficiencies, optimize safety, and reduce human error.

dowidth.com

dowidth.com