Machine vision systems utilize advanced cameras and AI algorithms to automate the inspection process, enhancing detection accuracy of defects on production lines compared to traditional quality control systems that often rely on manual inspection. By integrating real-time image processing and pattern recognition, machine vision offers consistent and objective quality assessments, reducing human error and increasing throughput. Discover how machine vision can revolutionize your manufacturing quality control by exploring its key advantages.

Why it is important

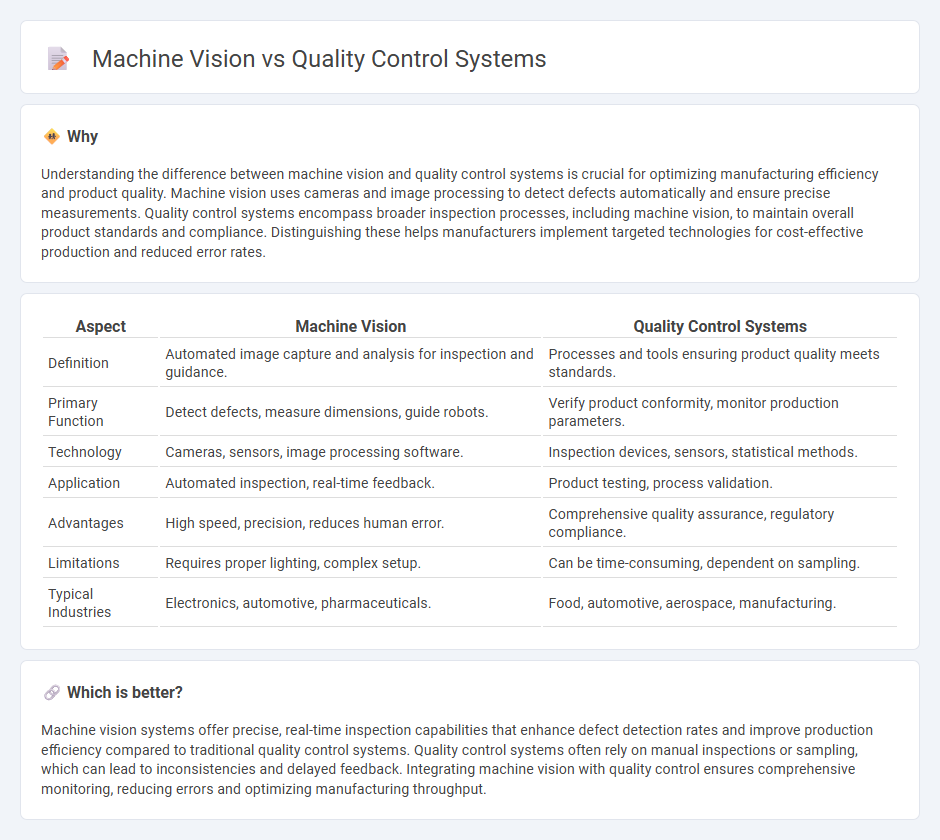

Understanding the difference between machine vision and quality control systems is crucial for optimizing manufacturing efficiency and product quality. Machine vision uses cameras and image processing to detect defects automatically and ensure precise measurements. Quality control systems encompass broader inspection processes, including machine vision, to maintain overall product standards and compliance. Distinguishing these helps manufacturers implement targeted technologies for cost-effective production and reduced error rates.

Comparison Table

| Aspect | Machine Vision | Quality Control Systems |

|---|---|---|

| Definition | Automated image capture and analysis for inspection and guidance. | Processes and tools ensuring product quality meets standards. |

| Primary Function | Detect defects, measure dimensions, guide robots. | Verify product conformity, monitor production parameters. |

| Technology | Cameras, sensors, image processing software. | Inspection devices, sensors, statistical methods. |

| Application | Automated inspection, real-time feedback. | Product testing, process validation. |

| Advantages | High speed, precision, reduces human error. | Comprehensive quality assurance, regulatory compliance. |

| Limitations | Requires proper lighting, complex setup. | Can be time-consuming, dependent on sampling. |

| Typical Industries | Electronics, automotive, pharmaceuticals. | Food, automotive, aerospace, manufacturing. |

Which is better?

Machine vision systems offer precise, real-time inspection capabilities that enhance defect detection rates and improve production efficiency compared to traditional quality control systems. Quality control systems often rely on manual inspections or sampling, which can lead to inconsistencies and delayed feedback. Integrating machine vision with quality control ensures comprehensive monitoring, reducing errors and optimizing manufacturing throughput.

Connection

Machine vision systems play a critical role in manufacturing quality control by providing automated inspection and defect detection with high precision and speed. These systems utilize advanced imaging technologies and AI algorithms to analyze products on the production line, ensuring consistency and adherence to quality standards. Integrating machine vision with quality control reduces human error, enhances product reliability, and minimizes downtime in manufacturing processes.

Key Terms

Statistical Process Control (SPC)

Statistical Process Control (SPC) enhances quality control systems by monitoring and controlling manufacturing processes through real-time data analysis to reduce variability and defects. Machine vision integrates with SPC by providing automated inspection and precise measurements, enabling faster detection of anomalies and ensuring consistent product quality. Explore how combining SPC with machine vision technology can revolutionize quality assurance in your production line.

Defect Detection

Quality control systems integrate various inspection methods to identify defects, ensuring product consistency and compliance with industry standards. Machine vision leverages advanced cameras and AI algorithms to detect surface flaws, dimensional inaccuracies, and assembly errors in real-time, enhancing accuracy and speed compared to traditional methods. Discover how combining quality control systems with machine vision can revolutionize defect detection in manufacturing.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) leverages advanced machine vision technologies to enhance quality control systems by rapidly detecting defects in manufacturing processes with high precision and minimal human intervention. Quality control systems focus on comprehensive product evaluation integrating various methods, while AOI specifically uses cameras and image processing algorithms to identify surface flaws, misalignments, and missing components on printed circuit boards and other assemblies. Explore deeper insights into how AOI transforms industrial inspection and boosts production efficiency.

Source and External Links

What Is A Quality Control System? A Deep Dive Into Its Role And ... - This article provides an in-depth look at quality control systems, highlighting their key features such as standards, inspection mechanisms, feedback loops, and documentation.

Quality management system - Wikipedia - This page discusses the concept of a quality management system, detailing its components and requirements, including management controls and corrective actions.

What is a Quality Management System (QMS)? - ASQ - This resource explains a quality management system as a structured framework that defines processes and responsibilities to achieve quality objectives and improve organizational performance.

dowidth.com

dowidth.com