Robotic Process Automation (RPA) streamlines repetitive manufacturing tasks by automating software-driven processes, enhancing efficiency and reducing human error. The Industrial Internet of Things (IIoT) integrates advanced sensors and connected devices on the factory floor to collect real-time data, enabling predictive maintenance and optimized production workflows. Explore the distinct benefits and applications of RPA and IIoT to transform modern manufacturing operations.

Why it is important

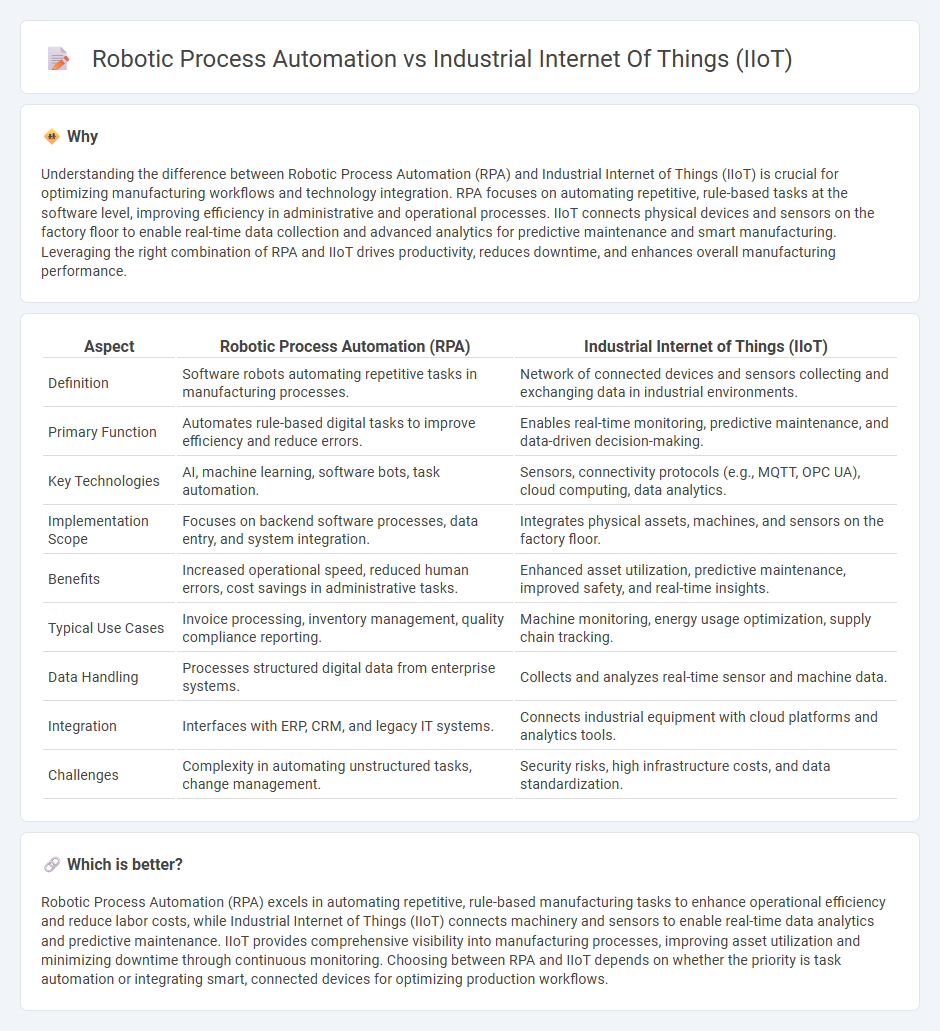

Understanding the difference between Robotic Process Automation (RPA) and Industrial Internet of Things (IIoT) is crucial for optimizing manufacturing workflows and technology integration. RPA focuses on automating repetitive, rule-based tasks at the software level, improving efficiency in administrative and operational processes. IIoT connects physical devices and sensors on the factory floor to enable real-time data collection and advanced analytics for predictive maintenance and smart manufacturing. Leveraging the right combination of RPA and IIoT drives productivity, reduces downtime, and enhances overall manufacturing performance.

Comparison Table

| Aspect | Robotic Process Automation (RPA) | Industrial Internet of Things (IIoT) |

|---|---|---|

| Definition | Software robots automating repetitive tasks in manufacturing processes. | Network of connected devices and sensors collecting and exchanging data in industrial environments. |

| Primary Function | Automates rule-based digital tasks to improve efficiency and reduce errors. | Enables real-time monitoring, predictive maintenance, and data-driven decision-making. |

| Key Technologies | AI, machine learning, software bots, task automation. | Sensors, connectivity protocols (e.g., MQTT, OPC UA), cloud computing, data analytics. |

| Implementation Scope | Focuses on backend software processes, data entry, and system integration. | Integrates physical assets, machines, and sensors on the factory floor. |

| Benefits | Increased operational speed, reduced human errors, cost savings in administrative tasks. | Enhanced asset utilization, predictive maintenance, improved safety, and real-time insights. |

| Typical Use Cases | Invoice processing, inventory management, quality compliance reporting. | Machine monitoring, energy usage optimization, supply chain tracking. |

| Data Handling | Processes structured digital data from enterprise systems. | Collects and analyzes real-time sensor and machine data. |

| Integration | Interfaces with ERP, CRM, and legacy IT systems. | Connects industrial equipment with cloud platforms and analytics tools. |

| Challenges | Complexity in automating unstructured tasks, change management. | Security risks, high infrastructure costs, and data standardization. |

Which is better?

Robotic Process Automation (RPA) excels in automating repetitive, rule-based manufacturing tasks to enhance operational efficiency and reduce labor costs, while Industrial Internet of Things (IIoT) connects machinery and sensors to enable real-time data analytics and predictive maintenance. IIoT provides comprehensive visibility into manufacturing processes, improving asset utilization and minimizing downtime through continuous monitoring. Choosing between RPA and IIoT depends on whether the priority is task automation or integrating smart, connected devices for optimizing production workflows.

Connection

Robotic Process Automation (RPA) enhances manufacturing efficiency by automating repetitive tasks, while Industrial Internet of Things (IIoT) connects machines and sensors to collect real-time data. The integration of RPA with IIoT enables predictive maintenance, reduces downtime, and optimizes production workflows through data-driven decisions. This synergy drives smart manufacturing by improving operational accuracy and enabling seamless communication between digital and physical systems.

Key Terms

Sensors and Connectivity

Industrial Internet of Things (IIoT) leverages advanced sensors and seamless connectivity to collect real-time data from machinery, enabling predictive maintenance and operational efficiency. Robotic Process Automation (RPA) focuses on automating repetitive digital tasks without relying on physical sensors or connected devices, enhancing workflow speed and accuracy. Explore how integrating IIoT's sensor data with RPA can transform industrial processes by visiting our detailed insights.

Data Integration

Industrial Internet of Things (IIoT) leverages connected sensors and devices to collect real-time data across manufacturing systems, enabling enhanced operational visibility and predictive maintenance. Robotic Process Automation (RPA) focuses on automating repetitive, rule-based tasks by integrating and processing data from multiple enterprise applications to improve efficiency. Explore how combining IIoT and RPA data integration strategies can optimize industrial workflows and drive digital transformation.

Workflow Automation

Industrial Internet of Things (IIoT) integrates connected sensors and devices within manufacturing environments to collect real-time data, optimizing operational workflows through enhanced visibility and predictive maintenance. Robotic Process Automation (RPA) focuses on automating repetitive, rule-based digital tasks to streamline business workflows and reduce human error. Explore how combining IIoT and RPA can revolutionize workflow automation and advance industrial efficiency.

Source and External Links

Industrial IoT | Digital Transformation - IIoT integrates machines, cloud computing, analytics, and people to enhance performance, productivity, and quality in industrial processes such as manufacturing and energy, using sensor data for predictive quality and optimizing operations.

What is IIoT (Industrial Internet of Things)? | Definition from ... - IIoT connects smart sensors and devices in industries like manufacturing and energy to collect and analyze data for improved efficiency, reliability, predictive maintenance, and supply chain optimization.

The Industrial Internet of Things: A Primer - IIoT platforms combine hardware and software to connect industrial machines with information systems, enabling centralized control, data-driven insights, predictive maintenance, and operational efficiency improvements.

dowidth.com

dowidth.com