Cobots, or collaborative robots, are designed to work safely alongside human operators, enhancing flexibility and precision in manufacturing processes. Unlike traditional robotic arms that operate autonomously in segregated zones, cobots enable seamless human-machine interaction, improving efficiency and reducing downtime. Discover how integrating cobots can revolutionize your manufacturing workflow.

Why it is important

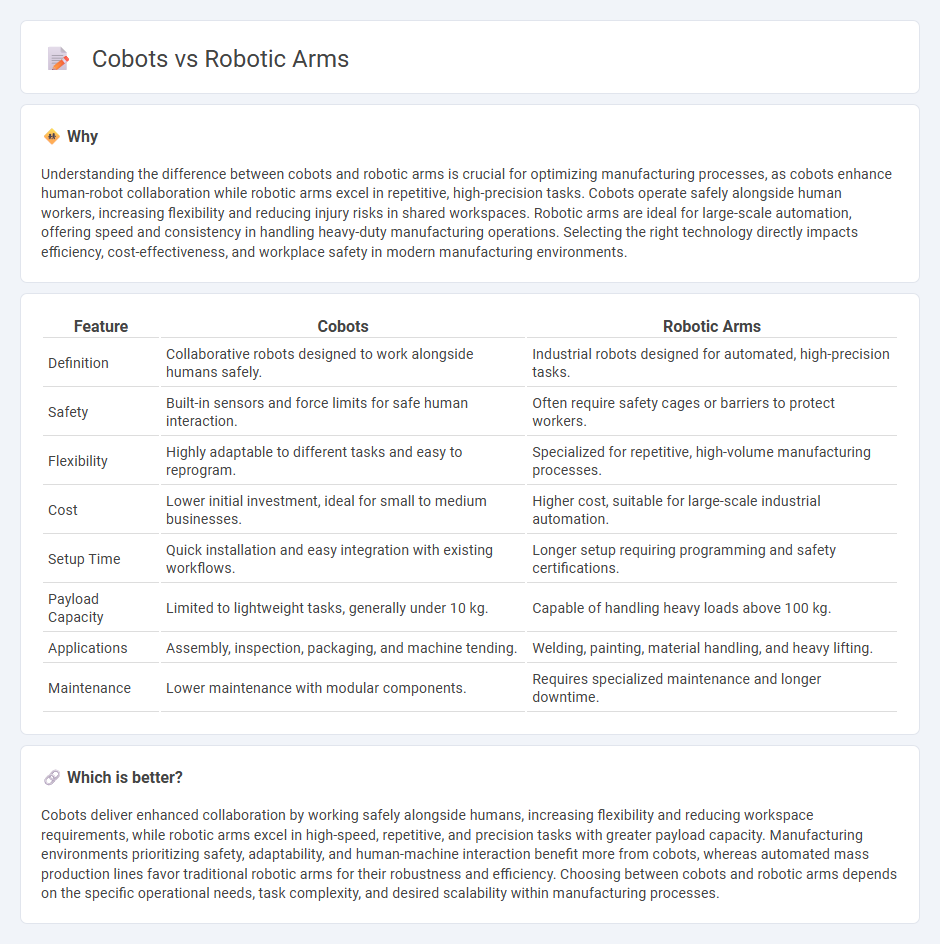

Understanding the difference between cobots and robotic arms is crucial for optimizing manufacturing processes, as cobots enhance human-robot collaboration while robotic arms excel in repetitive, high-precision tasks. Cobots operate safely alongside human workers, increasing flexibility and reducing injury risks in shared workspaces. Robotic arms are ideal for large-scale automation, offering speed and consistency in handling heavy-duty manufacturing operations. Selecting the right technology directly impacts efficiency, cost-effectiveness, and workplace safety in modern manufacturing environments.

Comparison Table

| Feature | Cobots | Robotic Arms |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans safely. | Industrial robots designed for automated, high-precision tasks. |

| Safety | Built-in sensors and force limits for safe human interaction. | Often require safety cages or barriers to protect workers. |

| Flexibility | Highly adaptable to different tasks and easy to reprogram. | Specialized for repetitive, high-volume manufacturing processes. |

| Cost | Lower initial investment, ideal for small to medium businesses. | Higher cost, suitable for large-scale industrial automation. |

| Setup Time | Quick installation and easy integration with existing workflows. | Longer setup requiring programming and safety certifications. |

| Payload Capacity | Limited to lightweight tasks, generally under 10 kg. | Capable of handling heavy loads above 100 kg. |

| Applications | Assembly, inspection, packaging, and machine tending. | Welding, painting, material handling, and heavy lifting. |

| Maintenance | Lower maintenance with modular components. | Requires specialized maintenance and longer downtime. |

Which is better?

Cobots deliver enhanced collaboration by working safely alongside humans, increasing flexibility and reducing workspace requirements, while robotic arms excel in high-speed, repetitive, and precision tasks with greater payload capacity. Manufacturing environments prioritizing safety, adaptability, and human-machine interaction benefit more from cobots, whereas automated mass production lines favor traditional robotic arms for their robustness and efficiency. Choosing between cobots and robotic arms depends on the specific operational needs, task complexity, and desired scalability within manufacturing processes.

Connection

Cobots and robotic arms are interconnected through advanced automation technologies that enable seamless collaboration between human operators and machines. Integrated sensors and AI-driven control systems allow cobots to work safely alongside humans, enhancing precision and efficiency in manufacturing processes. This connectivity streamlines production lines, reduces downtime, and improves overall operational productivity.

Key Terms

Automation

Robotic arms excel in repetitive, high-precision tasks within manufacturing and automotive sectors, delivering consistent speed and accuracy. Cobots, designed to work alongside humans, enhance flexibility and safety in automation processes, particularly in small to medium-sized enterprises. Explore how integrating robotic arms and cobots can revolutionize your automation strategy.

Human-robot collaboration

Human-robot collaboration enhances productivity and safety by combining the precision of robotic arms with the adaptability of cobots designed to work alongside humans. Cobots feature advanced sensors and AI algorithms to detect human presence, allowing seamless and safe interaction without extensive safety barriers. Discover how evolving technologies are reshaping collaborative automation and driving innovation in industrial workflows.

Safety systems

Robotic arms typically operate within safeguarded environments and rely on physical barriers and emergency stop systems to ensure operator safety. Cobots, or collaborative robots, integrate advanced safety features such as force-limited joints, proximity sensors, and real-time human detection to enable safe interaction alongside human workers without extensive guarding. Explore the latest advancements in safety systems to optimize your automation setup.

Source and External Links

Robotic Arms: Different Types and When to Use Them | HowToRobot - Robotic arms come in various types, including articulated, six-axis, collaborative, SCARA, Cartesian, cylindrical, spherical/polar, parallel/delta, and anthropomorphic, each optimized for different industrial tasks and environments.

Top Applications Of Robotic Arms - Dorna Robotics - Robotic arms are widely used for precise diagnostic testing, surgery, quality control, welding, and material handling across industries such as electronics, aerospace, food production, chemical plants, and mining due to their accuracy, speed, and safety benefits.

Robotic Arms in Manufacturing: How and Where They're Used - In manufacturing, robotic arms, including collaborative robots or cobots, automate repetitive tasks like pallet stacking and material handling, improving consistency, productivity, and workplace safety while reducing labor costs.

dowidth.com

dowidth.com