Digital thread integrates data flow across the manufacturing lifecycle, enabling traceability and real-time analytics from design to production. Smart factory utilizes IoT, automation, and AI to optimize manufacturing processes, increase efficiency, and reduce downtime through interconnected systems. Discover how these technologies transform modern manufacturing by exploring their unique roles and benefits.

Why it is important

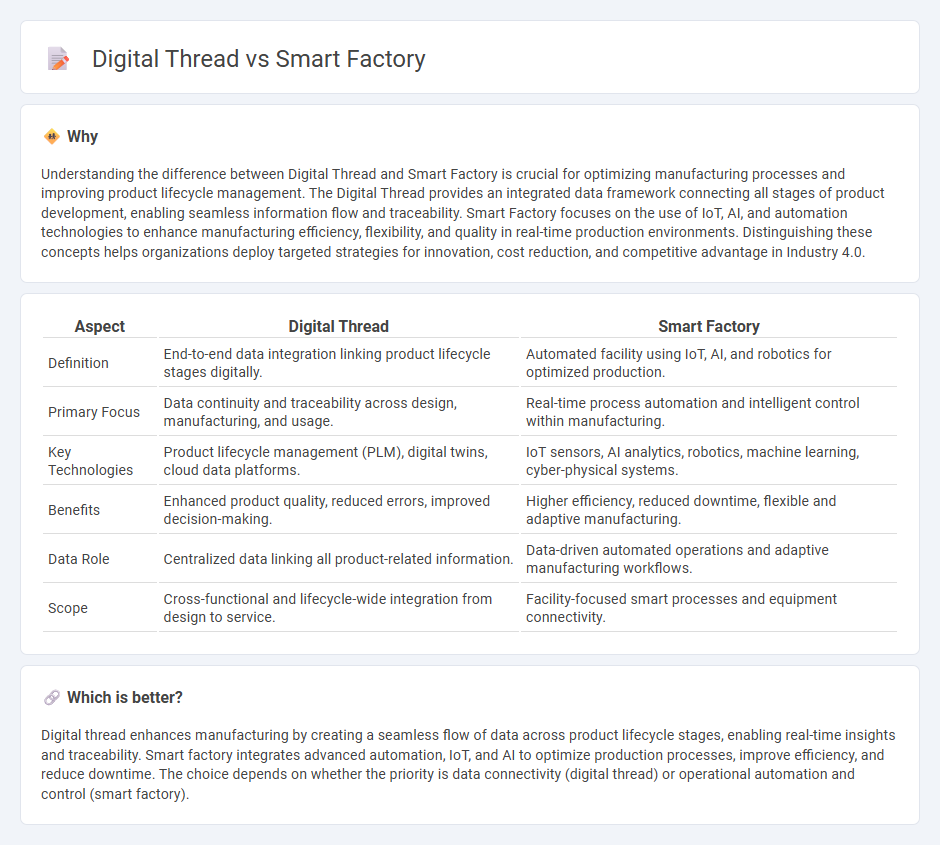

Understanding the difference between Digital Thread and Smart Factory is crucial for optimizing manufacturing processes and improving product lifecycle management. The Digital Thread provides an integrated data framework connecting all stages of product development, enabling seamless information flow and traceability. Smart Factory focuses on the use of IoT, AI, and automation technologies to enhance manufacturing efficiency, flexibility, and quality in real-time production environments. Distinguishing these concepts helps organizations deploy targeted strategies for innovation, cost reduction, and competitive advantage in Industry 4.0.

Comparison Table

| Aspect | Digital Thread | Smart Factory |

|---|---|---|

| Definition | End-to-end data integration linking product lifecycle stages digitally. | Automated facility using IoT, AI, and robotics for optimized production. |

| Primary Focus | Data continuity and traceability across design, manufacturing, and usage. | Real-time process automation and intelligent control within manufacturing. |

| Key Technologies | Product lifecycle management (PLM), digital twins, cloud data platforms. | IoT sensors, AI analytics, robotics, machine learning, cyber-physical systems. |

| Benefits | Enhanced product quality, reduced errors, improved decision-making. | Higher efficiency, reduced downtime, flexible and adaptive manufacturing. |

| Data Role | Centralized data linking all product-related information. | Data-driven automated operations and adaptive manufacturing workflows. |

| Scope | Cross-functional and lifecycle-wide integration from design to service. | Facility-focused smart processes and equipment connectivity. |

Which is better?

Digital thread enhances manufacturing by creating a seamless flow of data across product lifecycle stages, enabling real-time insights and traceability. Smart factory integrates advanced automation, IoT, and AI to optimize production processes, improve efficiency, and reduce downtime. The choice depends on whether the priority is data connectivity (digital thread) or operational automation and control (smart factory).

Connection

Digital thread integrates data across the entire manufacturing lifecycle, enabling seamless communication between design, production, and supply chain processes. Smart factories leverage this continuous data flow to optimize operations through real-time monitoring, predictive maintenance, and automation. This connectivity enhances efficiency, reduces downtime, and accelerates product innovation within manufacturing environments.

Key Terms

Smart factory:

A Smart Factory integrates advanced technologies such as IoT, AI, and robotics to optimize manufacturing processes, enhance productivity, and enable real-time decision-making. Unlike the Digital Thread, which connects data throughout a product's lifecycle, the Smart Factory focuses on operational efficiency within the production environment. Explore how Smart Factory solutions revolutionize Industry 4.0 for deeper insights.

Automation

Smart factories leverage interconnected automation systems to optimize production efficiency, integrating IoT devices, robotics, and AI-driven analytics for real-time process control. Digital thread connects data across the entire product lifecycle, enabling seamless traceability and informed decision-making through automated data flow from design to manufacturing. Explore how automation unites smart factories and digital thread to revolutionize industrial operations.

IoT (Internet of Things)

Smart factories leverage IoT technologies to enable real-time data collection, automation, and improved operational efficiency across manufacturing processes. The digital thread integrates IoT-generated data to create a continuous, traceable flow of information throughout the product lifecycle, enhancing connectivity between design, production, and supply chain management. Discover how combining smart factory IoT capabilities with the digital thread drives innovation and competitive advantage in Industry 4.0.

Source and External Links

What Is a Smart Factory? An Expert Guide - A smart factory is a highly automated, digitally connected manufacturing environment that integrates machines, data analytics, AI, and human insight to continuously optimize production, improve quality, and adapt in real time.

What is a smart factory? How to build - A smart factory enables smart manufacturing by digitalizing all aspects of production, using sensors, cloud computing, and AI to collect and analyze data for real-time process improvements and decision-making.

Smart Factory Guide | L2L - A smart factory connects machines, people, and processes through digital technologies and data analytics to boost efficiency, quality, and cost reduction across manufacturing operations.

dowidth.com

dowidth.com