Human augmentation enhances manufacturing efficiency by integrating wearable technology and robotics to improve worker precision and safety, while predictive maintenance leverages IoT sensors and AI algorithms to anticipate equipment failures and reduce downtime. Both approaches increase productivity and operational resilience through advanced data analytics and automation. Explore the latest innovations shaping the future of manufacturing performance.

Why it is important

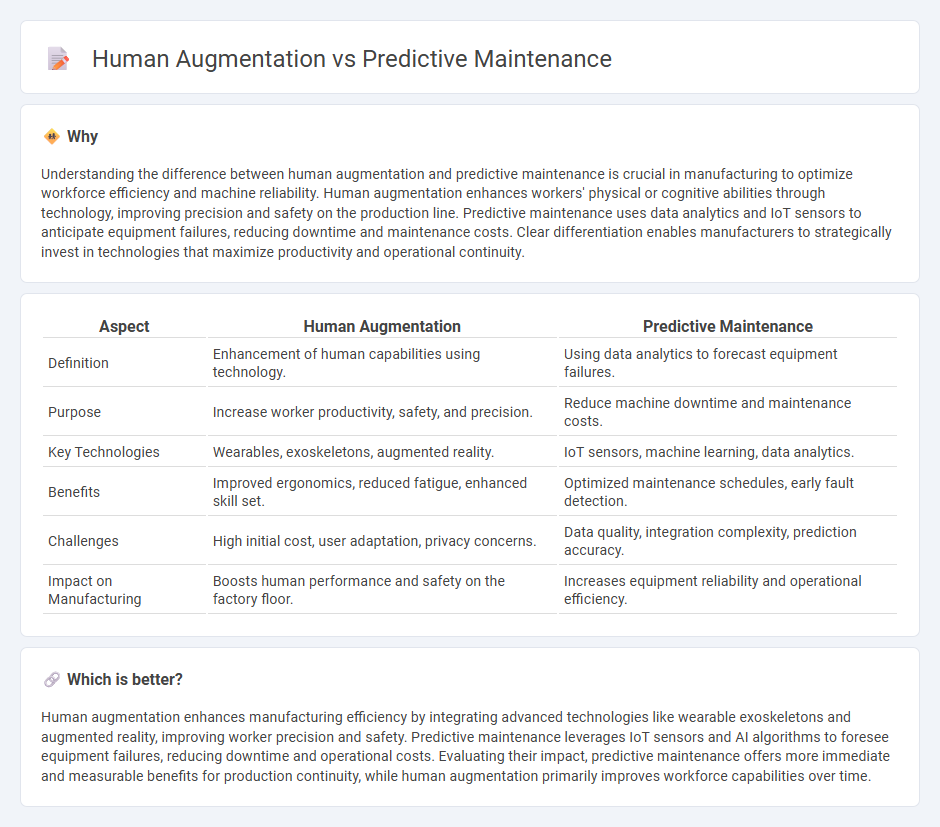

Understanding the difference between human augmentation and predictive maintenance is crucial in manufacturing to optimize workforce efficiency and machine reliability. Human augmentation enhances workers' physical or cognitive abilities through technology, improving precision and safety on the production line. Predictive maintenance uses data analytics and IoT sensors to anticipate equipment failures, reducing downtime and maintenance costs. Clear differentiation enables manufacturers to strategically invest in technologies that maximize productivity and operational continuity.

Comparison Table

| Aspect | Human Augmentation | Predictive Maintenance |

|---|---|---|

| Definition | Enhancement of human capabilities using technology. | Using data analytics to forecast equipment failures. |

| Purpose | Increase worker productivity, safety, and precision. | Reduce machine downtime and maintenance costs. |

| Key Technologies | Wearables, exoskeletons, augmented reality. | IoT sensors, machine learning, data analytics. |

| Benefits | Improved ergonomics, reduced fatigue, enhanced skill set. | Optimized maintenance schedules, early fault detection. |

| Challenges | High initial cost, user adaptation, privacy concerns. | Data quality, integration complexity, prediction accuracy. |

| Impact on Manufacturing | Boosts human performance and safety on the factory floor. | Increases equipment reliability and operational efficiency. |

Which is better?

Human augmentation enhances manufacturing efficiency by integrating advanced technologies like wearable exoskeletons and augmented reality, improving worker precision and safety. Predictive maintenance leverages IoT sensors and AI algorithms to foresee equipment failures, reducing downtime and operational costs. Evaluating their impact, predictive maintenance offers more immediate and measurable benefits for production continuity, while human augmentation primarily improves workforce capabilities over time.

Connection

Human augmentation in manufacturing enhances workers' physical and cognitive abilities through wearable devices and exoskeletons, enabling more precise and efficient tasks. Predictive maintenance utilizes IoT sensors and machine learning algorithms to monitor equipment health in real-time, reducing unexpected downtime. The integration of these technologies creates a synergistic environment where augmented workers use predictive insights to perform timely maintenance, improving overall operational productivity.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages advanced sensors, machine learning algorithms, and IoT data to anticipate equipment failures before they occur, reducing downtime and maintenance costs significantly. It improves operational efficiency by enabling timely interventions based on real-time analytics and historical performance trends, extending the lifespan of critical assets. Explore the latest innovations and case studies in predictive maintenance to enhance manufacturing reliability and productivity.

Condition Monitoring

Predictive maintenance leverages advanced condition monitoring technologies, such as IoT sensors and machine learning algorithms, to analyze real-time equipment data and forecast potential failures, minimizing unplanned downtime and reducing maintenance costs. Human augmentation enhances condition monitoring by integrating augmented reality (AR), wearable devices, and AI-driven decision support systems, enabling technicians to interpret complex data more accurately and perform timely interventions with greater efficiency. Explore more to understand how these technologies transform industrial asset management and operational reliability.

Failure Prediction

Predictive maintenance leverages AI-driven analytics and sensor data to anticipate equipment failures, minimizing downtime and optimizing operational efficiency. Human augmentation enhances technicians' capabilities through wearable devices and real-time insights, enabling faster, more accurate failure diagnosis and intervention. Explore how combining predictive maintenance with human augmentation transforms failure prediction and improves asset reliability.

Source and External Links

What is Predictive Maintenance? - Predictive maintenance uses sensor data and machine learning to assess equipment health in real time, enabling maintenance only when needed to reduce downtime and costs while optimizing performance and lifespan.

Predictive maintenance - This technique estimates when maintenance should be performed by measuring actual equipment condition, helping schedule repairs in advance, reduce unplanned stops, and improve safety and equipment lifetime.

What is Predictive Maintenance? Benefits, Challenges & ... - Predictive maintenance analyzes real-time vehicle sensor data to predict failures weeks in advance, improving fleet uptime, reducing costs, and optimizing maintenance priorities through data-driven alerts.

dowidth.com

dowidth.com