Industrial metaverse transforms manufacturing by integrating digital twins, IoT, and AI to create immersive virtual environments that optimize production processes and predictive maintenance. Human-robot collaboration enhances efficiency and safety on the factory floor by combining robotic precision with human adaptability and decision-making. Explore the potential of these technologies to revolutionize industrial operations and drive innovation.

Why it is important

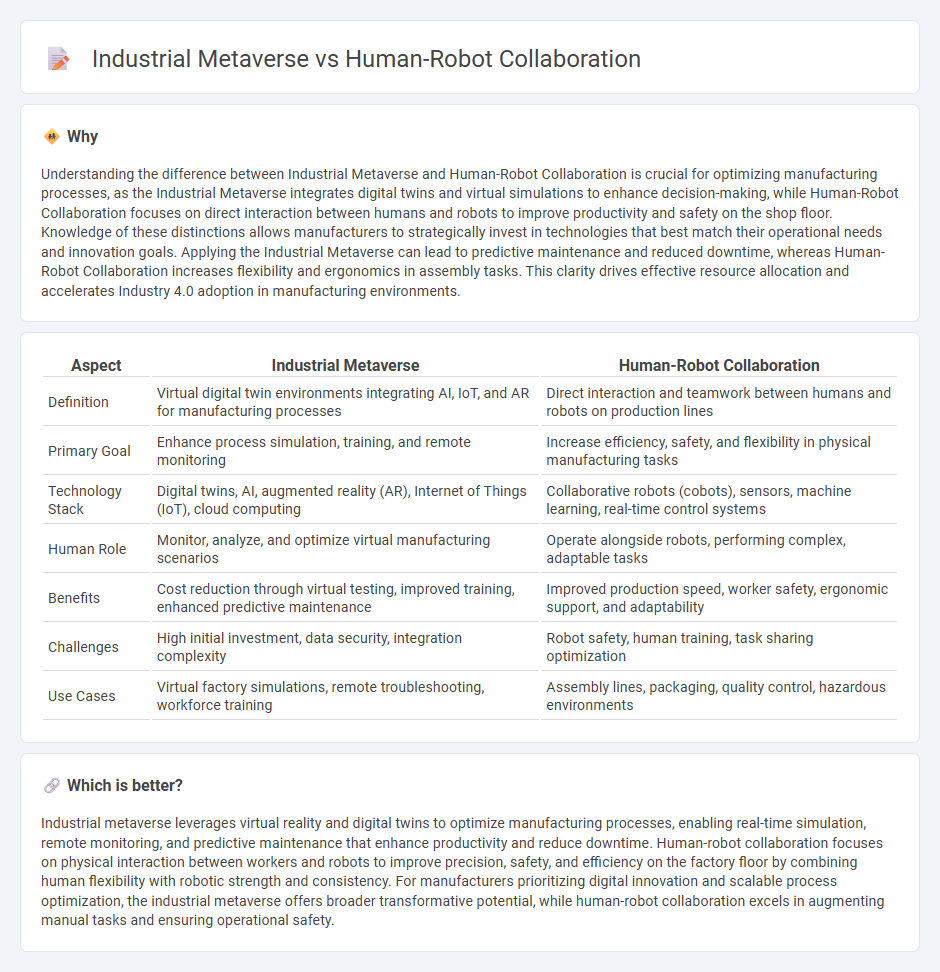

Understanding the difference between Industrial Metaverse and Human-Robot Collaboration is crucial for optimizing manufacturing processes, as the Industrial Metaverse integrates digital twins and virtual simulations to enhance decision-making, while Human-Robot Collaboration focuses on direct interaction between humans and robots to improve productivity and safety on the shop floor. Knowledge of these distinctions allows manufacturers to strategically invest in technologies that best match their operational needs and innovation goals. Applying the Industrial Metaverse can lead to predictive maintenance and reduced downtime, whereas Human-Robot Collaboration increases flexibility and ergonomics in assembly tasks. This clarity drives effective resource allocation and accelerates Industry 4.0 adoption in manufacturing environments.

Comparison Table

| Aspect | Industrial Metaverse | Human-Robot Collaboration |

|---|---|---|

| Definition | Virtual digital twin environments integrating AI, IoT, and AR for manufacturing processes | Direct interaction and teamwork between humans and robots on production lines |

| Primary Goal | Enhance process simulation, training, and remote monitoring | Increase efficiency, safety, and flexibility in physical manufacturing tasks |

| Technology Stack | Digital twins, AI, augmented reality (AR), Internet of Things (IoT), cloud computing | Collaborative robots (cobots), sensors, machine learning, real-time control systems |

| Human Role | Monitor, analyze, and optimize virtual manufacturing scenarios | Operate alongside robots, performing complex, adaptable tasks |

| Benefits | Cost reduction through virtual testing, improved training, enhanced predictive maintenance | Improved production speed, worker safety, ergonomic support, and adaptability |

| Challenges | High initial investment, data security, integration complexity | Robot safety, human training, task sharing optimization |

| Use Cases | Virtual factory simulations, remote troubleshooting, workforce training | Assembly lines, packaging, quality control, hazardous environments |

Which is better?

Industrial metaverse leverages virtual reality and digital twins to optimize manufacturing processes, enabling real-time simulation, remote monitoring, and predictive maintenance that enhance productivity and reduce downtime. Human-robot collaboration focuses on physical interaction between workers and robots to improve precision, safety, and efficiency on the factory floor by combining human flexibility with robotic strength and consistency. For manufacturers prioritizing digital innovation and scalable process optimization, the industrial metaverse offers broader transformative potential, while human-robot collaboration excels in augmenting manual tasks and ensuring operational safety.

Connection

Industrial metaverse platforms create immersive digital twins of manufacturing environments, enabling seamless human-robot collaboration by enhancing real-time data sharing and remote control capabilities. These virtual environments simulate complex production workflows, allowing workers and robots to interact safely and optimize processes through synchronized task execution. Leveraging augmented reality and AI-driven analytics, the industrial metaverse facilitates adaptive learning and proactive maintenance, improving efficiency and reducing downtime in human-robot collaborative manufacturing settings.

Key Terms

Cobots

Human-robot collaboration enhances production efficiency by integrating collaborative robots (cobots) that work safely alongside human operators, improving precision and flexibility in manufacturing tasks. The industrial metaverse expands this concept by creating immersive digital twins where cobots and human workflows can be simulated and optimized in real time, enabling advanced training and predictive maintenance. Explore the transformative impact of cobots within the industrial metaverse to unlock new levels of operational excellence.

Digital Twin

Human-robot collaboration integrates digital twin technology to create real-time, adaptive systems enhancing factory productivity and safety. The industrial metaverse expands this concept by immersing digital twins within a virtual ecosystem, enabling comprehensive simulation and remote interaction across decentralized environments. Explore how digital twin advancements redefine the synergy between physical and virtual industrial workflows.

Simulation

Human-robot collaboration enhances manufacturing efficiency by integrating real-time data with autonomous robotic actions, enabling adaptive responses to dynamic environments. Industrial metaverse leverages immersive simulation platforms to create digital twins that optimize production workflows and virtual prototyping at scale. Explore how these cutting-edge simulation technologies drive innovation and operational excellence in smart factories.

Source and External Links

Human-robot collaboration - Wikipedia - Human-robot collaboration (HRC) is the interdisciplinary study of how humans and robots work together in shared spaces to achieve common goals, combining expertise from robotics, AI, ergonomics, and psychology to enable safe and effective teamwork in diverse settings such as manufacturing, healthcare, and space exploration.

Human-Robot Collaborations in Smart Manufacturing - In HRC systems, humans and robots combine their respective strengths--human judgment and robot precision--to enhance productivity and flexibility in industrial processes, with a focus on safety through physical separation and advanced communication during direct collaboration.

Human - Robot Collaboration in Industry - Collaborative robotics, as part of Industry 4.0, enables humans and robots to share workspaces safely, with robots assisting in repetitive, ergonomically challenging, or hazardous tasks while using sensors to avoid endangering human coworkers.

dowidth.com

dowidth.com