Cobotics integrates collaborative robots into manufacturing processes, enhancing flexibility and worker safety while boosting productivity in small to medium-sized operations. Smart factories leverage advanced IoT technologies, AI, and automation to create highly efficient, interconnected production systems capable of real-time data analysis and adaptive decision-making. Discover more about how these innovations are transforming the future of manufacturing.

Why it is important

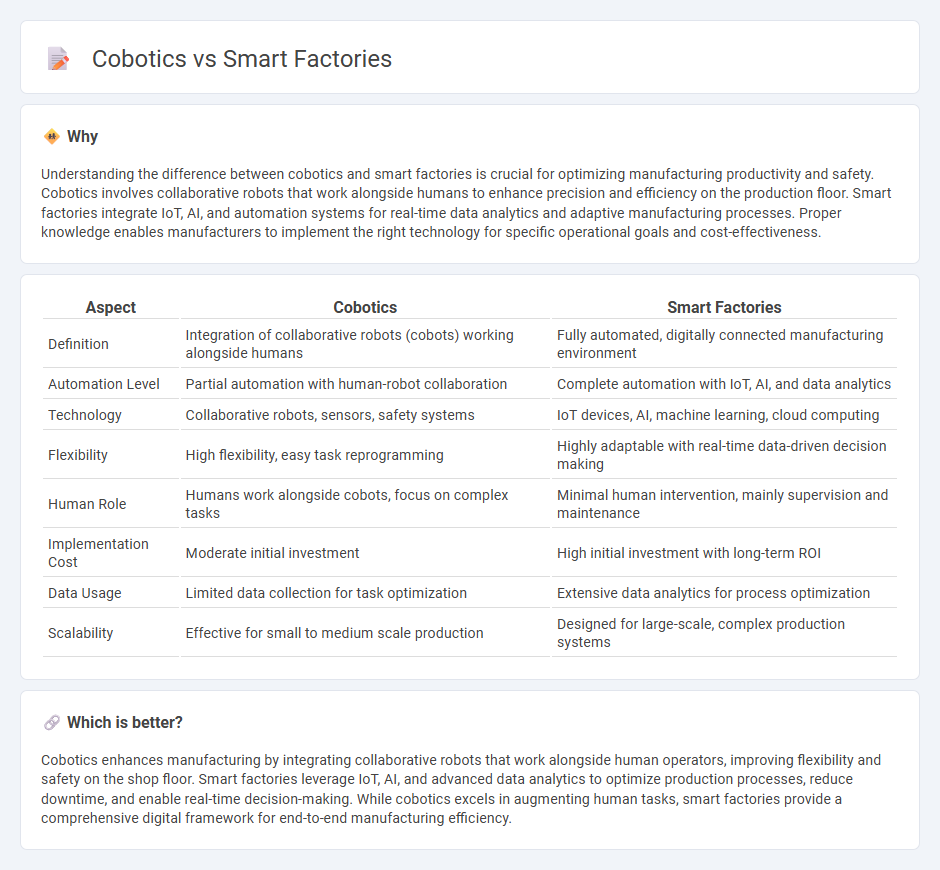

Understanding the difference between cobotics and smart factories is crucial for optimizing manufacturing productivity and safety. Cobotics involves collaborative robots that work alongside humans to enhance precision and efficiency on the production floor. Smart factories integrate IoT, AI, and automation systems for real-time data analytics and adaptive manufacturing processes. Proper knowledge enables manufacturers to implement the right technology for specific operational goals and cost-effectiveness.

Comparison Table

| Aspect | Cobotics | Smart Factories |

|---|---|---|

| Definition | Integration of collaborative robots (cobots) working alongside humans | Fully automated, digitally connected manufacturing environment |

| Automation Level | Partial automation with human-robot collaboration | Complete automation with IoT, AI, and data analytics |

| Technology | Collaborative robots, sensors, safety systems | IoT devices, AI, machine learning, cloud computing |

| Flexibility | High flexibility, easy task reprogramming | Highly adaptable with real-time data-driven decision making |

| Human Role | Humans work alongside cobots, focus on complex tasks | Minimal human intervention, mainly supervision and maintenance |

| Implementation Cost | Moderate initial investment | High initial investment with long-term ROI |

| Data Usage | Limited data collection for task optimization | Extensive data analytics for process optimization |

| Scalability | Effective for small to medium scale production | Designed for large-scale, complex production systems |

Which is better?

Cobotics enhances manufacturing by integrating collaborative robots that work alongside human operators, improving flexibility and safety on the shop floor. Smart factories leverage IoT, AI, and advanced data analytics to optimize production processes, reduce downtime, and enable real-time decision-making. While cobotics excels in augmenting human tasks, smart factories provide a comprehensive digital framework for end-to-end manufacturing efficiency.

Connection

Cobotics integrates collaborative robots within smart factories, enabling real-time data exchange and adaptive automation to enhance manufacturing efficiency. Smart factories utilize IoT sensors, AI analytics, and cloud connectivity to optimize production processes, where cobots work alongside humans to perform repetitive or precision tasks safely. This synergy drives increased productivity, reduced downtime, and scalable customization in modern manufacturing environments.

Key Terms

Automation

Smart factories integrate advanced IoT sensors, AI-driven analytics, and automated machinery to optimize production workflows and reduce human error. Cobotics centers on collaborative robots that work alongside human operators, enhancing flexibility and precision in automated tasks. Explore how these automation technologies transform industry efficiency and workforce dynamics.

Human-Robot Collaboration

Smart factories integrate advanced automation systems and IoT technologies to optimize manufacturing processes, while cobotics centers on direct Human-Robot Collaboration (HRC) for enhanced productivity and safety. Cobots are designed to work alongside human operators, improving precision and reducing ergonomic risks, which complements the data-driven efficiency of smart factories. Explore the evolving dynamics of HRC to unlock the full potential of industrial innovation.

Industrial IoT

Smart factories leverage Industrial IoT to create interconnected systems that enable real-time data collection, automated decision-making, and enhanced operational efficiency. Cobotics integrates collaborative robots with IoT sensors to facilitate seamless human-robot interaction, boosting productivity and safety on the factory floor. Explore how these technologies converge to transform manufacturing and drive Industry 4.0 advancements.

Source and External Links

9 Benefits of Smart Factories - Smart factories leverage IoT, AI, and real-time data analytics to boost efficiency, improve quality control, and enable flexible, customized production lines.

What is Smart Factory and Smart Manufacturing? - A smart factory is a highly interconnected production facility that uses real-time data from sensors and advanced robotics to optimize processes, predict maintenance, and improve decision-making across all operational levels.

What is a Smart Factory? - A smart factory integrates Industry 4.0 technologies like cloud computing and big data analytics to monitor and streamline the entire production process, enabling rapid issue detection and predictive maintenance for uninterrupted manufacturing.

dowidth.com

dowidth.com