Collaborative robots enhance manufacturing efficiency by performing repetitive, precise tasks while human workers focus on complex decision-making and problem-solving. These robots improve safety and productivity, working alongside humans without barriers. Discover how collaborative robots and human workers combine strengths to revolutionize manufacturing processes.

Why it is important

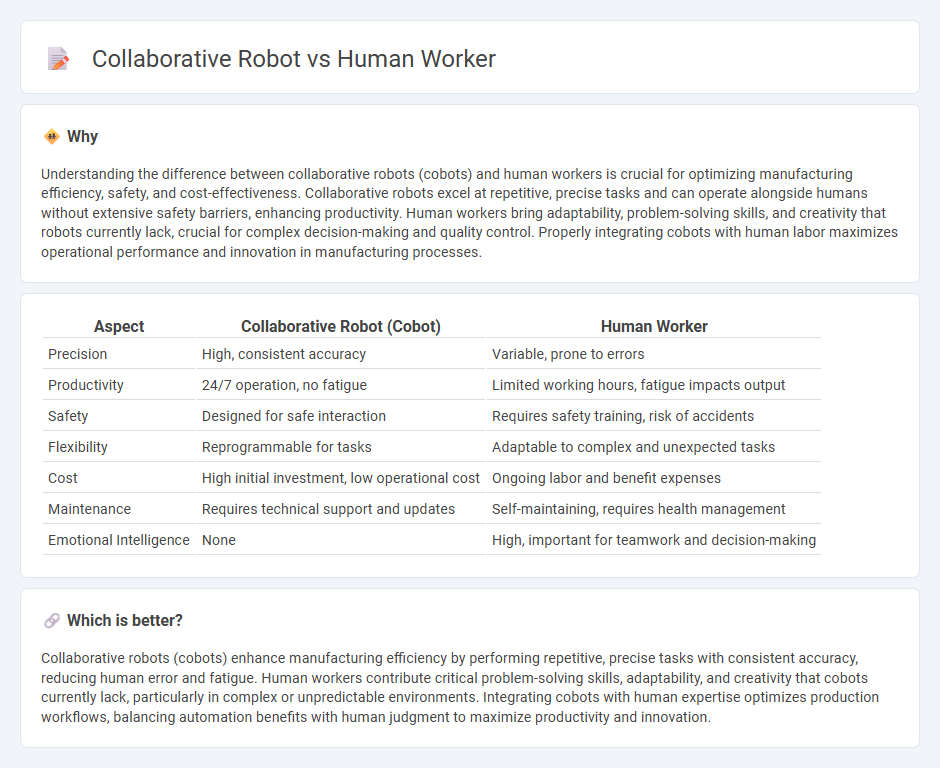

Understanding the difference between collaborative robots (cobots) and human workers is crucial for optimizing manufacturing efficiency, safety, and cost-effectiveness. Collaborative robots excel at repetitive, precise tasks and can operate alongside humans without extensive safety barriers, enhancing productivity. Human workers bring adaptability, problem-solving skills, and creativity that robots currently lack, crucial for complex decision-making and quality control. Properly integrating cobots with human labor maximizes operational performance and innovation in manufacturing processes.

Comparison Table

| Aspect | Collaborative Robot (Cobot) | Human Worker |

|---|---|---|

| Precision | High, consistent accuracy | Variable, prone to errors |

| Productivity | 24/7 operation, no fatigue | Limited working hours, fatigue impacts output |

| Safety | Designed for safe interaction | Requires safety training, risk of accidents |

| Flexibility | Reprogrammable for tasks | Adaptable to complex and unexpected tasks |

| Cost | High initial investment, low operational cost | Ongoing labor and benefit expenses |

| Maintenance | Requires technical support and updates | Self-maintaining, requires health management |

| Emotional Intelligence | None | High, important for teamwork and decision-making |

Which is better?

Collaborative robots (cobots) enhance manufacturing efficiency by performing repetitive, precise tasks with consistent accuracy, reducing human error and fatigue. Human workers contribute critical problem-solving skills, adaptability, and creativity that cobots currently lack, particularly in complex or unpredictable environments. Integrating cobots with human expertise optimizes production workflows, balancing automation benefits with human judgment to maximize productivity and innovation.

Connection

Collaborative robots (cobots) enhance manufacturing efficiency by working alongside human workers, sharing tasks that require precision and repetition while humans focus on complex decision-making and problem-solving. Sensors and advanced AI enable cobots to safely interact with humans, reducing workplace injuries and increasing productivity. This human-robot collaboration drives innovation in smart factories by combining machine accuracy with human creativity.

Key Terms

Safety

Collaborative robots (cobots) are designed with advanced safety features such as force limiters and sensors to detect human presence, reducing the risk of workplace injuries compared to traditional human workers. Safety standards like ISO/TS 15066 provide guidelines specifically for human-robot collaboration, ensuring cobots operate within safe parameters. Explore the latest advancements in collaborative robot safety to enhance your industrial environment.

Task Allocation

In task allocation, human workers excel in complex decision-making, adaptability, and problem-solving, while collaborative robots (cobots) provide consistent precision and endurance in repetitive or hazardous tasks. Effective integration maximizes productivity by leveraging human creativity alongside cobot efficiency in assembly lines, quality control, and material handling. Explore how optimized task distribution between humans and cobots enhances industrial performance and workforce satisfaction.

Human-Robot Interaction

Human-robot interaction (HRI) plays a critical role in optimizing workflows between human workers and collaborative robots (cobots) in industrial settings. Cobots are designed with advanced sensors and intuitive interfaces to safely assist humans, enhancing productivity and reducing workplace injuries. Explore the latest innovations in HRI technology to unlock new potentials in human-cobot collaboration.

Source and External Links

The Advantage of a Highly Trained Human Worker in the Digital Era - Human workers bring critical thinking, creativity, and emotional intelligence to complement technology, and continuous learning is essential for them to stay relevant in a rapidly changing digital environment.

Seven big advantages human workers have over AI - Human workers excel in jobs requiring physical strength and versatility, particularly in roles involving manipulation of physical objects and interpersonal services, areas where robots currently cannot fully replace humans.

The Human View of Robot Workers: What Do Employees Really Think - Human workers maintain competitiveness by focusing on decision-making, problem-solving, creativity, and interpersonal skills, which robots cannot replicate, and ongoing training helps them integrate with robotic technologies.

dowidth.com

dowidth.com