Microfactories concentrate production within compact, highly automated facilities designed for rapid customization and local distribution, significantly reducing lead times and logistics costs. Modular manufacturing relies on standardized, interchangeable units that streamline scalability and flexibility across diverse production setups, enabling efficient adjustments to demand fluctuations. Explore how microfactory and modular manufacturing models revolutionize industrial production efficiency and adaptability.

Why it is important

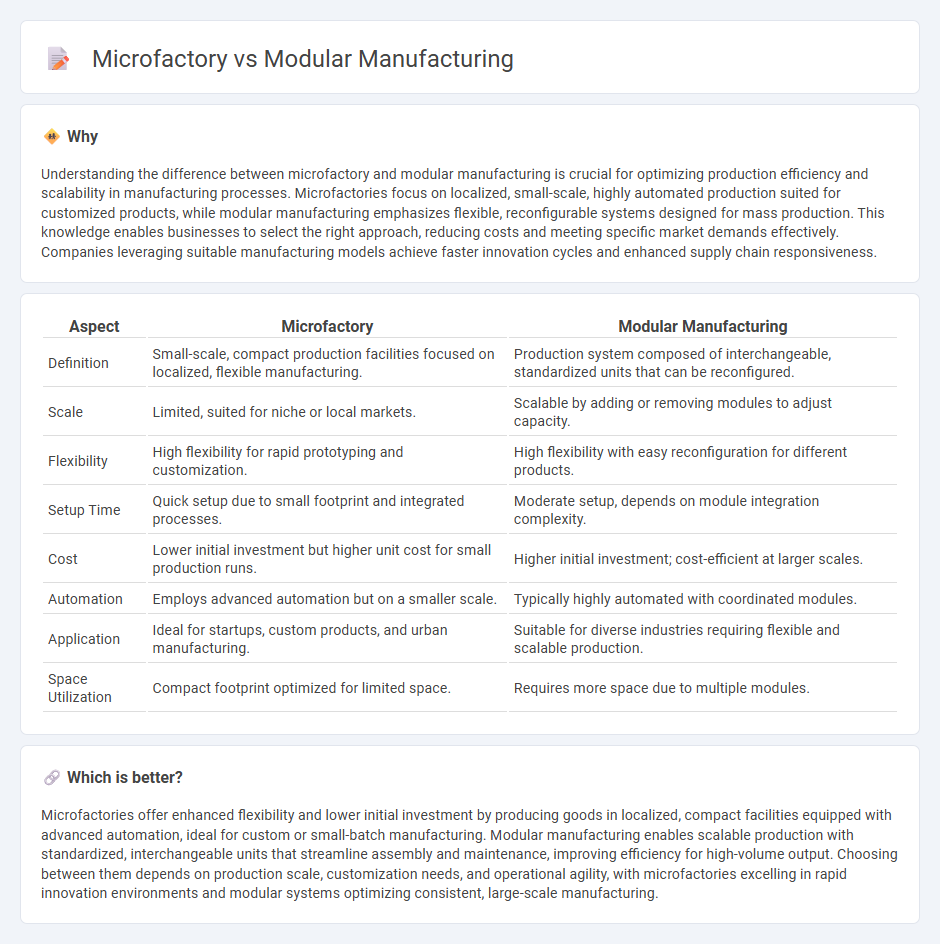

Understanding the difference between microfactory and modular manufacturing is crucial for optimizing production efficiency and scalability in manufacturing processes. Microfactories focus on localized, small-scale, highly automated production suited for customized products, while modular manufacturing emphasizes flexible, reconfigurable systems designed for mass production. This knowledge enables businesses to select the right approach, reducing costs and meeting specific market demands effectively. Companies leveraging suitable manufacturing models achieve faster innovation cycles and enhanced supply chain responsiveness.

Comparison Table

| Aspect | Microfactory | Modular Manufacturing |

|---|---|---|

| Definition | Small-scale, compact production facilities focused on localized, flexible manufacturing. | Production system composed of interchangeable, standardized units that can be reconfigured. |

| Scale | Limited, suited for niche or local markets. | Scalable by adding or removing modules to adjust capacity. |

| Flexibility | High flexibility for rapid prototyping and customization. | High flexibility with easy reconfiguration for different products. |

| Setup Time | Quick setup due to small footprint and integrated processes. | Moderate setup, depends on module integration complexity. |

| Cost | Lower initial investment but higher unit cost for small production runs. | Higher initial investment; cost-efficient at larger scales. |

| Automation | Employs advanced automation but on a smaller scale. | Typically highly automated with coordinated modules. |

| Application | Ideal for startups, custom products, and urban manufacturing. | Suitable for diverse industries requiring flexible and scalable production. |

| Space Utilization | Compact footprint optimized for limited space. | Requires more space due to multiple modules. |

Which is better?

Microfactories offer enhanced flexibility and lower initial investment by producing goods in localized, compact facilities equipped with advanced automation, ideal for custom or small-batch manufacturing. Modular manufacturing enables scalable production with standardized, interchangeable units that streamline assembly and maintenance, improving efficiency for high-volume output. Choosing between them depends on production scale, customization needs, and operational agility, with microfactories excelling in rapid innovation environments and modular systems optimizing consistent, large-scale manufacturing.

Connection

Microfactories utilize modular manufacturing principles by integrating compact, reconfigurable production units that enhance flexibility and scalability. Modular manufacturing enables rapid customization and efficient workflows within microfactories, reducing lead times and operational costs. This synergy supports localized production and agile responses to market demands, driving innovation in modern manufacturing systems.

Key Terms

Standardized Modules

Standardized modules in modular manufacturing enable scalable, repeatable production processes by using pre-engineered components designed for easy assembly and customization. Microfactories leverage these modules to create flexible, compact production units focused on local, on-demand manufacturing with faster turnaround times. Explore how standardized modules transform production efficiency and flexibility in modern manufacturing systems.

Decentralized Production

Decentralized production enhances flexibility and reduces transportation costs by distributing manufacturing processes across modular manufacturing units and microfactories. Modular manufacturing involves assembling standardized components in scalable units, while microfactories focus on compact, automated facilities tailored for local markets, boosting responsiveness and customization. Explore deeper insights on how decentralized production reshapes manufacturing efficiency and sustainability.

Scalability

Modular manufacturing offers rapid scalability through standardized, interchangeable units that can be easily expanded or reconfigured to meet changing production demands. Microfactories enable localized, small-batch production with flexibility but often face challenges in scaling operations quickly due to space and resource constraints. Explore the nuances of scalability between modular manufacturing and microfactory models to optimize your production strategy.

Source and External Links

The Benefits of Modular Design in Manufacturing - Tencom - Modular manufacturing produces standardized, interchangeable modules simultaneously in different locations, enabling efficient assembly, cost savings, flexibility, and rapid response to market changes across industries like automotive, electronics, construction, and aerospace.

Modular Manufacturing - Last Energy - Modular manufacturing utilizes standardized, compatible modules produced at various facilities and assembled later, improving efficiency, sustainability, flexibility in supply chains, and innovation by simplifying upgrades and reducing production bottlenecks.

Modular manufacturing systems - EIT Manufacturing - Modular manufacturing systems increase operational flexibility by enabling easily reconfigurable, scalable production lines composed of modular units, which can be moved and adapted quickly to changing production needs and conditions.

dowidth.com

dowidth.com