Biofabrication leverages biological materials and living cells to create functional tissue and organ structures, expanding possibilities within regenerative medicine. Additive manufacturing, commonly known as 3D printing, builds components layer by layer from digital models using polymers, metals, or ceramics, enhancing precision and customization in production. Discover how these innovative manufacturing techniques are transforming industries and healthcare by exploring their unique applications and benefits.

Why it is important

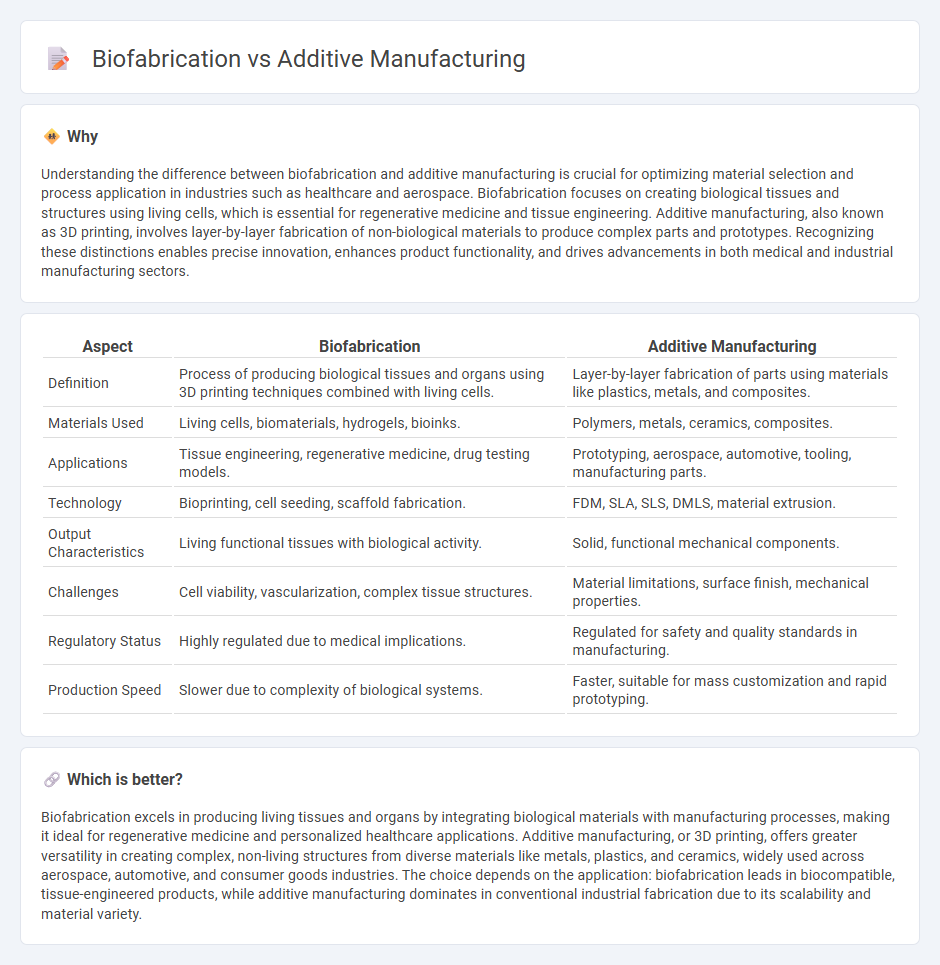

Understanding the difference between biofabrication and additive manufacturing is crucial for optimizing material selection and process application in industries such as healthcare and aerospace. Biofabrication focuses on creating biological tissues and structures using living cells, which is essential for regenerative medicine and tissue engineering. Additive manufacturing, also known as 3D printing, involves layer-by-layer fabrication of non-biological materials to produce complex parts and prototypes. Recognizing these distinctions enables precise innovation, enhances product functionality, and drives advancements in both medical and industrial manufacturing sectors.

Comparison Table

| Aspect | Biofabrication | Additive Manufacturing |

|---|---|---|

| Definition | Process of producing biological tissues and organs using 3D printing techniques combined with living cells. | Layer-by-layer fabrication of parts using materials like plastics, metals, and composites. |

| Materials Used | Living cells, biomaterials, hydrogels, bioinks. | Polymers, metals, ceramics, composites. |

| Applications | Tissue engineering, regenerative medicine, drug testing models. | Prototyping, aerospace, automotive, tooling, manufacturing parts. |

| Technology | Bioprinting, cell seeding, scaffold fabrication. | FDM, SLA, SLS, DMLS, material extrusion. |

| Output Characteristics | Living functional tissues with biological activity. | Solid, functional mechanical components. |

| Challenges | Cell viability, vascularization, complex tissue structures. | Material limitations, surface finish, mechanical properties. |

| Regulatory Status | Highly regulated due to medical implications. | Regulated for safety and quality standards in manufacturing. |

| Production Speed | Slower due to complexity of biological systems. | Faster, suitable for mass customization and rapid prototyping. |

Which is better?

Biofabrication excels in producing living tissues and organs by integrating biological materials with manufacturing processes, making it ideal for regenerative medicine and personalized healthcare applications. Additive manufacturing, or 3D printing, offers greater versatility in creating complex, non-living structures from diverse materials like metals, plastics, and ceramics, widely used across aerospace, automotive, and consumer goods industries. The choice depends on the application: biofabrication leads in biocompatible, tissue-engineered products, while additive manufacturing dominates in conventional industrial fabrication due to its scalability and material variety.

Connection

Biofabrication and additive manufacturing are interconnected through their shared use of layer-by-layer construction techniques to create complex biological structures and components. Both methods leverage computer-aided design (CAD) and precise material deposition technologies to fabricate customized, functional products ranging from medical implants to tissue scaffolds. The integration of biofabrication with additive manufacturing enables advancements in regenerative medicine and personalized healthcare by producing biologically compatible materials with controlled architecture and properties.

Key Terms

3D Printing

Additive manufacturing and biofabrication are revolutionizing 3D printing by enabling the precise layer-by-layer creation of complex structures, with additive manufacturing primarily used for metals, plastics, and ceramics, while biofabrication targets the production of biological tissues and organs using living cells and biomaterials. Advances in bioprinting techniques such as inkjet, extrusion, and laser-based methods optimize cellular viability and functional tissue development, critical for regenerative medicine and drug testing. Explore deeper insights into how these technologies are shaping the future of manufacturing and healthcare innovation.

Biomaterials

Additive manufacturing employs a variety of synthetic polymers and metals to create precise, customizable structures, while biofabrication emphasizes biocompatible and biodegradable biomaterials such as hydrogels, collagen, and decellularized extracellular matrices to replicate native tissue environments. Biomaterials in biofabrication are designed to support cell viability, proliferation, and differentiation, making them critical for applications in tissue engineering and regenerative medicine. Explore the latest advancements in biomaterial development to understand their transformative impact on additive manufacturing and biofabrication technologies.

Tissue Engineering

Additive manufacturing in tissue engineering involves layer-by-layer deposition of biomaterials to create scaffolds that support cell growth, offering precise control over scaffold architecture and porosity. Biofabrication extends this concept by integrating living cells directly into the manufacturing process, enabling the creation of complex, functional tissue constructs that closely mimic native biological structures. Explore more to understand how these technologies revolutionize tissue regeneration and personalized medicine.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing builds objects layer by layer from digital designs, evolving from rapid prototyping in the 1980s to producing functional products using various materials such as polymers, metals, and biomaterials.

Additive manufacturing | NIST - Additive manufacturing uses digital designs to fabricate complex 3D products by layering materials like metal, plastic, or ceramic, enabling lightweight aerospace structures and customized biomedical implants while reducing waste compared to traditional manufacturing.

What Is Additive Manufacturing? | 3D Printing Simulation Software - Additive manufacturing involves building 3D objects from CAD models by layering materials via technologies such as powder bed fusion, material extrusion, binder jetting, photopolymerization, and direct energy deposition, targeting industrial applications including prototypes and production parts.

dowidth.com

dowidth.com