Additive manufacturing builds complex parts layer by layer using digital models, offering design flexibility and reduced waste. Powder metallurgy compacts and sinters metal powders into solid components, optimizing material properties and enabling mass production. Explore the key differences and applications of these advanced manufacturing techniques to enhance your production strategy.

Why it is important

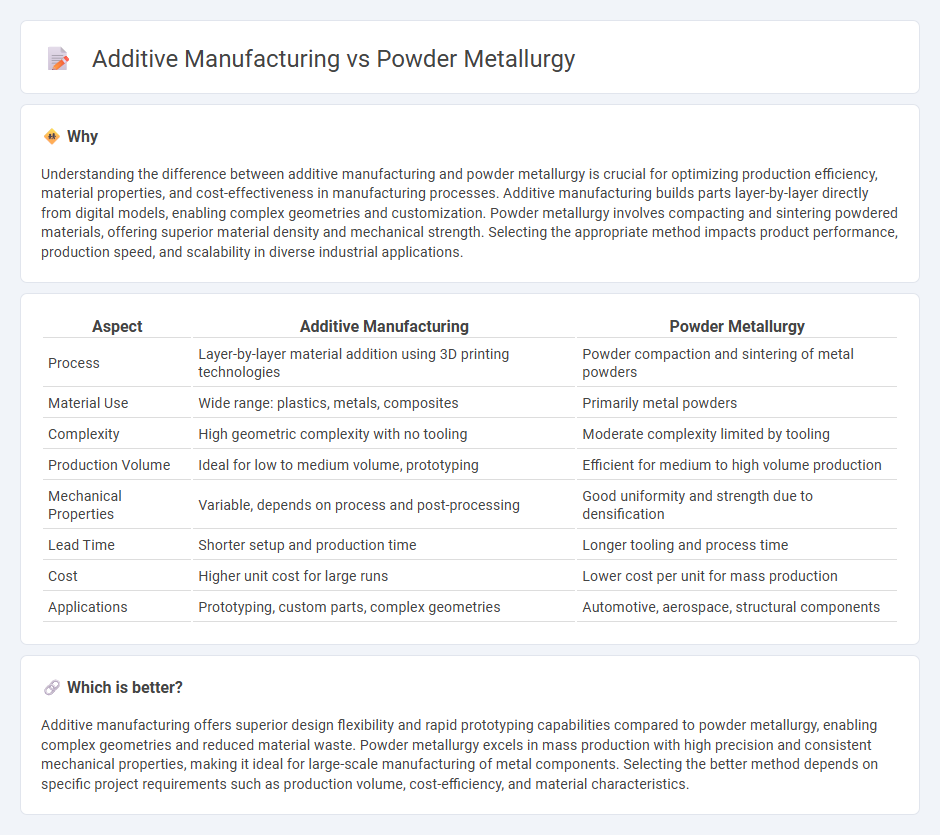

Understanding the difference between additive manufacturing and powder metallurgy is crucial for optimizing production efficiency, material properties, and cost-effectiveness in manufacturing processes. Additive manufacturing builds parts layer-by-layer directly from digital models, enabling complex geometries and customization. Powder metallurgy involves compacting and sintering powdered materials, offering superior material density and mechanical strength. Selecting the appropriate method impacts product performance, production speed, and scalability in diverse industrial applications.

Comparison Table

| Aspect | Additive Manufacturing | Powder Metallurgy |

|---|---|---|

| Process | Layer-by-layer material addition using 3D printing technologies | Powder compaction and sintering of metal powders |

| Material Use | Wide range: plastics, metals, composites | Primarily metal powders |

| Complexity | High geometric complexity with no tooling | Moderate complexity limited by tooling |

| Production Volume | Ideal for low to medium volume, prototyping | Efficient for medium to high volume production |

| Mechanical Properties | Variable, depends on process and post-processing | Good uniformity and strength due to densification |

| Lead Time | Shorter setup and production time | Longer tooling and process time |

| Cost | Higher unit cost for large runs | Lower cost per unit for mass production |

| Applications | Prototyping, custom parts, complex geometries | Automotive, aerospace, structural components |

Which is better?

Additive manufacturing offers superior design flexibility and rapid prototyping capabilities compared to powder metallurgy, enabling complex geometries and reduced material waste. Powder metallurgy excels in mass production with high precision and consistent mechanical properties, making it ideal for large-scale manufacturing of metal components. Selecting the better method depends on specific project requirements such as production volume, cost-efficiency, and material characteristics.

Connection

Additive manufacturing and powder metallurgy are interconnected through their reliance on powdered materials to create complex, high-precision components layer by layer. Both techniques utilize metal powders, which are selectively fused or sintered to produce parts with minimal waste and superior mechanical properties. This synergy enhances customization, reduces lead times, and supports lightweight, durable designs in aerospace, automotive, and medical industries.

Key Terms

Powder Metallurgy:

Powder metallurgy offers precise control over material composition and microstructure, enabling the production of complex, high-strength components with minimal waste. This manufacturing process excels in mass production of metal parts, offering superior mechanical properties and cost efficiency compared to traditional casting methods. Explore the advantages, applications, and innovations in powder metallurgy to understand its critical role in modern manufacturing.

Sintering

Powder metallurgy relies on sintering to bond metal particles through heat below melting points, resulting in dense, strong components with excellent mechanical properties. Additive manufacturing sintering, particularly in techniques like selective laser sintering (SLS), uses a laser to fuse powdered material layer-by-layer, offering complex geometries and minimal waste compared to traditional sintering. Explore detailed insights on sintering differences to optimize manufacturing processes and material performance.

Compaction

Powder metallurgy and additive manufacturing both utilize powder compaction but differ significantly in process and application. Powder metallurgy employs high-pressure compaction followed by sintering to create dense, uniform parts ideal for mass production of metal components. Discover more about how these techniques optimize material properties through compaction by exploring their detailed processes and industrial uses.

Source and External Links

Powder metallurgy - Wikipedia - Powder metallurgy involves compressing metal powder into a shape and heating it (sintering) below its melting point to form solid parts, commonly using iron powder with additives; it allows precise parts but with some porosity and sub-wrought steel properties.

What is Powder Metallurgy? - Knife Steel Nerds - Powder metallurgy uses rapid solidification and gas atomization to produce fine metal powders that can be pressed and consolidated into steels with fine carbide distributions and enhanced toughness, originally for high alloy tool steels.

The Advantages & Disadvantages of Powder Metallurgy - Powder metallurgy is cost-effective and environmentally friendly, minimizing waste by using over 97% of starting material and allowing precise control of final part properties like porosity and hardness via selection of powder and sintering parameters.

dowidth.com

dowidth.com