Collaborative robots enhance manufacturing efficiency by working safely alongside human operators, performing precision tasks with adaptability and reducing labor costs. Smart conveyors integrate IoT sensors and automation to optimize material flow, monitor system performance, and minimize downtime through real-time data analysis. Explore the differences and benefits of collaborative robots versus smart conveyors to revolutionize manufacturing processes.

Why it is important

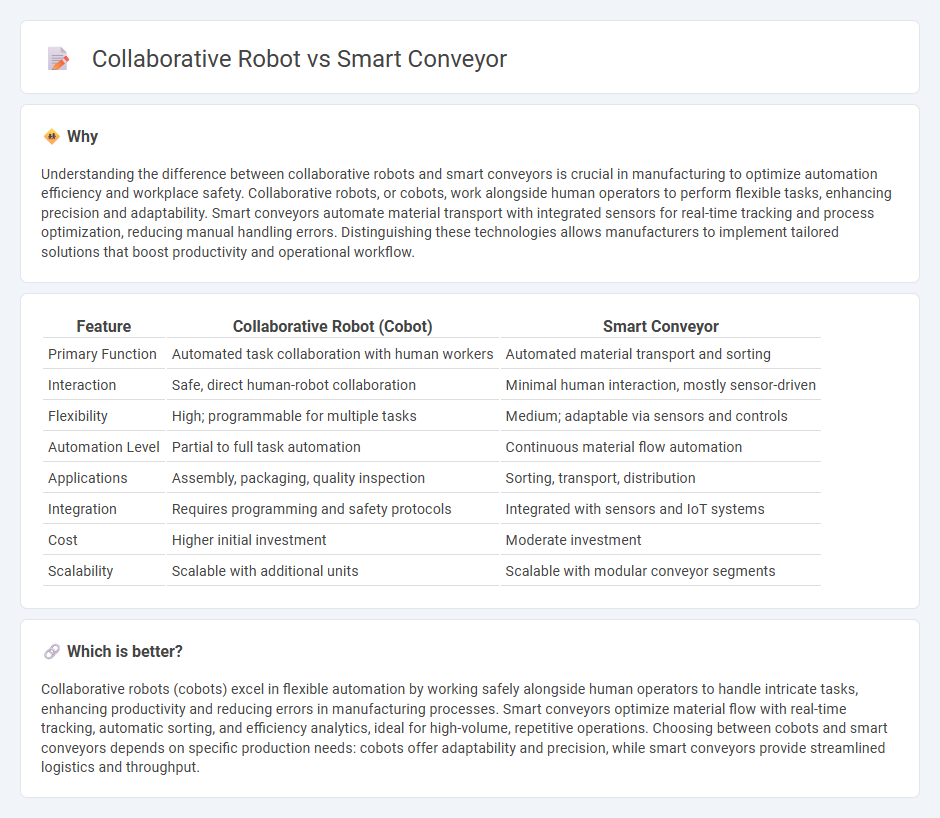

Understanding the difference between collaborative robots and smart conveyors is crucial in manufacturing to optimize automation efficiency and workplace safety. Collaborative robots, or cobots, work alongside human operators to perform flexible tasks, enhancing precision and adaptability. Smart conveyors automate material transport with integrated sensors for real-time tracking and process optimization, reducing manual handling errors. Distinguishing these technologies allows manufacturers to implement tailored solutions that boost productivity and operational workflow.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Smart Conveyor |

|---|---|---|

| Primary Function | Automated task collaboration with human workers | Automated material transport and sorting |

| Interaction | Safe, direct human-robot collaboration | Minimal human interaction, mostly sensor-driven |

| Flexibility | High; programmable for multiple tasks | Medium; adaptable via sensors and controls |

| Automation Level | Partial to full task automation | Continuous material flow automation |

| Applications | Assembly, packaging, quality inspection | Sorting, transport, distribution |

| Integration | Requires programming and safety protocols | Integrated with sensors and IoT systems |

| Cost | Higher initial investment | Moderate investment |

| Scalability | Scalable with additional units | Scalable with modular conveyor segments |

Which is better?

Collaborative robots (cobots) excel in flexible automation by working safely alongside human operators to handle intricate tasks, enhancing productivity and reducing errors in manufacturing processes. Smart conveyors optimize material flow with real-time tracking, automatic sorting, and efficiency analytics, ideal for high-volume, repetitive operations. Choosing between cobots and smart conveyors depends on specific production needs: cobots offer adaptability and precision, while smart conveyors provide streamlined logistics and throughput.

Connection

Collaborative robots (cobots) and smart conveyors integrate seamlessly to enhance manufacturing automation by enabling synchronized material handling and assembly processes. Cobots equipped with sensors communicate with smart conveyors using IoT protocols to optimize workflow, reduce downtime, and increase throughput. This connectivity facilitates real-time data exchange, improving precision and efficiency across production lines.

Key Terms

Automation

Smart conveyors integrate sensors and IoT technology to optimize material handling by enabling real-time tracking and adaptive speed control, significantly increasing efficiency in automated workflows. Collaborative robots (cobots) enhance automation by working alongside human operators, providing flexible and precise task execution without the need for extensive safety barriers. Explore how these automation technologies can transform production lines and improve operational productivity.

Flexibility

Smart conveyors offer high flexibility by adapting to varying product sizes and speeds through programmable controls and modular designs, enhancing material handling efficiency. Collaborative robots (cobots) provide unmatched flexibility by learning and adjusting to diverse tasks and working safely alongside humans in dynamic production environments. Explore deeper insights to understand how both technologies transform manufacturing flexibility.

Human-robot interaction

Smart conveyors enhance human-robot interaction by automating material transport with built-in sensors and AI-driven adjustments, reducing manual handling and minimizing errors. Collaborative robots (cobots) work alongside humans, equipped with advanced safety features and adaptive controls to enable seamless teamwork in shared workspaces. Explore the nuances of human-robot collaboration to optimize industrial efficiency and safety.

Source and External Links

What Makes a Smart Conveyor System "Smart"? - Smart conveyors integrate motion control (e.g., servo motors, encoders), artificial intelligence, and smart sensors to precisely track and control individual materials, enabling autonomous decision-making and synchronization with other machines.

Smart Conveyors - These conveyors offer features such as energy efficiency, motion control, high-speed connectivity, and precision movement, boosting productivity and efficiency across manufacturing and shipping industries.

SmartMove(r) Conveyors - A manufacturer of safe, modular conveyors with plug-and-play designs, customizable for various industrial applications, emphasizing operator safety and ease of expansion without technicians.

dowidth.com

dowidth.com