Collaborative robots (cobots) and flexible automation systems both enhance manufacturing efficiency by adapting to various tasks with precision and speed. Cobots are designed to safely work alongside human operators, improving productivity while maintaining safety, whereas flexible automation systems offer high adaptability for complex, repetitive tasks across multiple production lines. Explore the key differences and benefits of each technology to determine the best fit for your manufacturing needs.

Why it is important

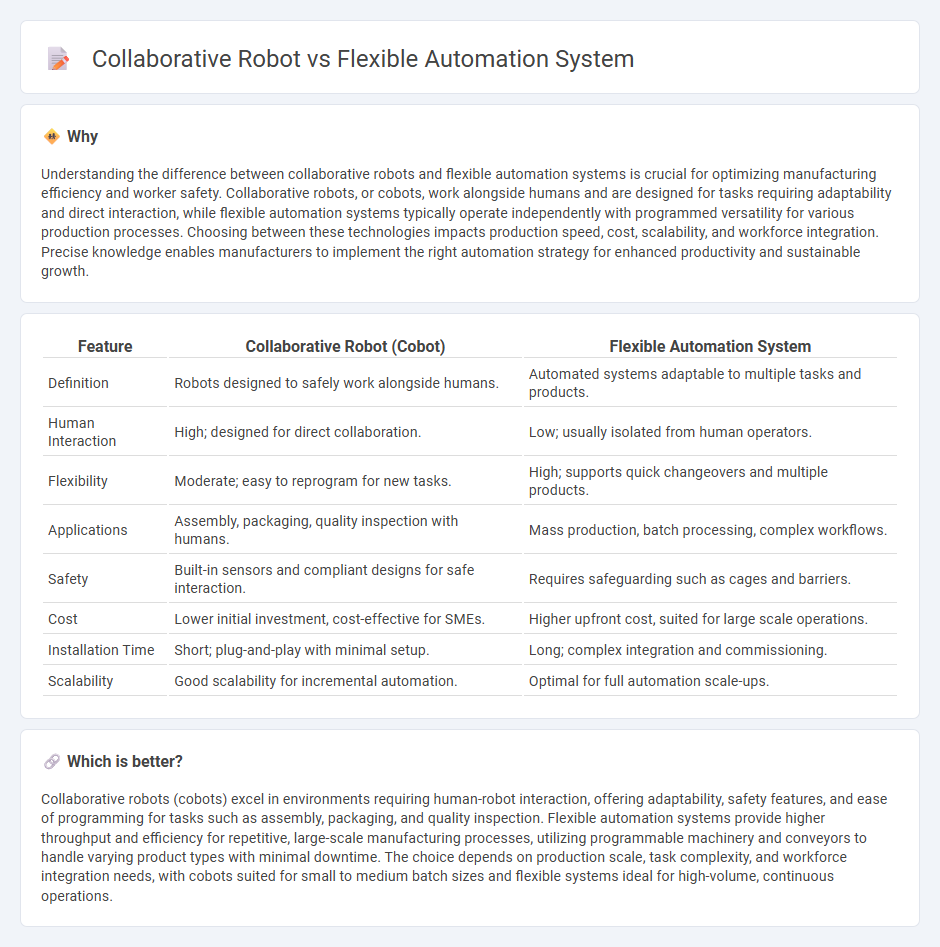

Understanding the difference between collaborative robots and flexible automation systems is crucial for optimizing manufacturing efficiency and worker safety. Collaborative robots, or cobots, work alongside humans and are designed for tasks requiring adaptability and direct interaction, while flexible automation systems typically operate independently with programmed versatility for various production processes. Choosing between these technologies impacts production speed, cost, scalability, and workforce integration. Precise knowledge enables manufacturers to implement the right automation strategy for enhanced productivity and sustainable growth.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Flexible Automation System |

|---|---|---|

| Definition | Robots designed to safely work alongside humans. | Automated systems adaptable to multiple tasks and products. |

| Human Interaction | High; designed for direct collaboration. | Low; usually isolated from human operators. |

| Flexibility | Moderate; easy to reprogram for new tasks. | High; supports quick changeovers and multiple products. |

| Applications | Assembly, packaging, quality inspection with humans. | Mass production, batch processing, complex workflows. |

| Safety | Built-in sensors and compliant designs for safe interaction. | Requires safeguarding such as cages and barriers. |

| Cost | Lower initial investment, cost-effective for SMEs. | Higher upfront cost, suited for large scale operations. |

| Installation Time | Short; plug-and-play with minimal setup. | Long; complex integration and commissioning. |

| Scalability | Good scalability for incremental automation. | Optimal for full automation scale-ups. |

Which is better?

Collaborative robots (cobots) excel in environments requiring human-robot interaction, offering adaptability, safety features, and ease of programming for tasks such as assembly, packaging, and quality inspection. Flexible automation systems provide higher throughput and efficiency for repetitive, large-scale manufacturing processes, utilizing programmable machinery and conveyors to handle varying product types with minimal downtime. The choice depends on production scale, task complexity, and workforce integration needs, with cobots suited for small to medium batch sizes and flexible systems ideal for high-volume, continuous operations.

Connection

Collaborative robots (cobots) integrate seamlessly with flexible automation systems by enhancing adaptability and precision in manufacturing processes. Cobots work alongside human operators, enabling dynamic task sharing and real-time adjustments within automated production lines. This synergy improves efficiency, reduces downtime, and supports scalable manufacturing operations across diverse industrial applications.

Key Terms

**Flexible automation system:**

Flexible automation systems integrate programmable machinery designed for high adaptability and efficiency across diverse production tasks, enabling quick reconfiguration without significant downtime. These systems use advanced sensors and control technologies to optimize workflow, improve accuracy, and reduce labor costs in manufacturing environments. Discover how flexible automation systems can revolutionize your production line with enhanced versatility and productivity.

Changeover time

Flexible automation systems significantly reduce changeover time by enabling rapid reprogramming and tool swaps, enhancing production efficiency for varying tasks. Collaborative robots (cobots) offer quick adaptation with minimal setup and intuitive programming but may not match the scalability of flexible automation in high-volume environments. Explore detailed comparisons to determine the optimal solution for minimizing changeover time in your manufacturing process.

Programmable controllers

Flexible automation systems utilize programmable logic controllers (PLCs) to manage complex, high-volume production tasks with adaptability for various operations. Collaborative robots (cobots) often rely on embedded programmable controllers designed for safe human-robot interaction and easy reprogramming on the shop floor. Explore the differences in control strategies and programming approaches to enhance manufacturing efficiency.

Source and External Links

Flexible Automation in Industrial Settings - RT Engineering - Flexible automation uses reprogrammable, adaptable systems to handle varied tasks and product changes without major downtime, increasing manufacturing efficiency and adaptability.

How to Identify Flexible Automation for Your Warehouse - Flexible automation features modular, scalable equipment and software control, enabling quick adjustments for changing order volumes and dynamic task allocation based on real-time demand.

Flexible automation systems: Explained w/ examples - Standard Bots - Flexible automation combines CNC machines, robots, material handling systems, and central computers, allowing easy reprogramming and reconfiguration to produce a variety of products efficiently.

dowidth.com

dowidth.com