Lights-out manufacturing leverages fully automated, unmanned production facilities to enhance efficiency and reduce labor costs, enabling continuous operation and streamlined workflows. Mass customization combines the flexibility of custom-tailored products with the efficiency of mass production, allowing companies to meet individual customer demands at scale. Explore how integrating these strategies can revolutionize your manufacturing processes.

Why it is important

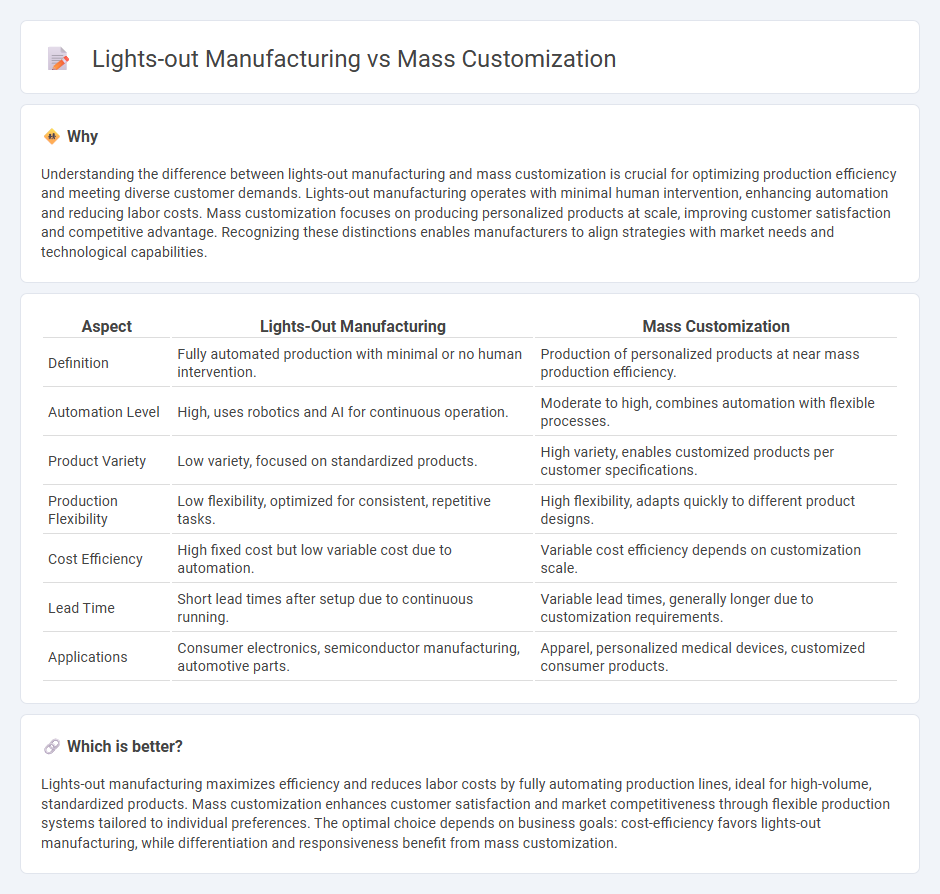

Understanding the difference between lights-out manufacturing and mass customization is crucial for optimizing production efficiency and meeting diverse customer demands. Lights-out manufacturing operates with minimal human intervention, enhancing automation and reducing labor costs. Mass customization focuses on producing personalized products at scale, improving customer satisfaction and competitive advantage. Recognizing these distinctions enables manufacturers to align strategies with market needs and technological capabilities.

Comparison Table

| Aspect | Lights-Out Manufacturing | Mass Customization |

|---|---|---|

| Definition | Fully automated production with minimal or no human intervention. | Production of personalized products at near mass production efficiency. |

| Automation Level | High, uses robotics and AI for continuous operation. | Moderate to high, combines automation with flexible processes. |

| Product Variety | Low variety, focused on standardized products. | High variety, enables customized products per customer specifications. |

| Production Flexibility | Low flexibility, optimized for consistent, repetitive tasks. | High flexibility, adapts quickly to different product designs. |

| Cost Efficiency | High fixed cost but low variable cost due to automation. | Variable cost efficiency depends on customization scale. |

| Lead Time | Short lead times after setup due to continuous running. | Variable lead times, generally longer due to customization requirements. |

| Applications | Consumer electronics, semiconductor manufacturing, automotive parts. | Apparel, personalized medical devices, customized consumer products. |

Which is better?

Lights-out manufacturing maximizes efficiency and reduces labor costs by fully automating production lines, ideal for high-volume, standardized products. Mass customization enhances customer satisfaction and market competitiveness through flexible production systems tailored to individual preferences. The optimal choice depends on business goals: cost-efficiency favors lights-out manufacturing, while differentiation and responsiveness benefit from mass customization.

Connection

Lights-out manufacturing leverages autonomous robots and AI-driven systems to operate factories with minimal human intervention, enabling continuous production and enhanced efficiency. This technology supports mass customization by allowing flexible, real-time adjustments to manufacturing processes, accommodating varied product specifications without extensive downtime. Integrating these innovations reduces operational costs and accelerates delivery times, meeting the growing demand for personalized products at scale.

Key Terms

Flexibility

Mass customization excels in flexibility by allowing tailored product variations to meet specific customer needs without sacrificing efficiency, leveraging modular design and advanced manufacturing technologies. Lights-out manufacturing emphasizes operational flexibility through fully automated, unattended production lines that can quickly adapt to different product types and volumes with minimal human intervention. Explore how integrating both approaches can maximize manufacturing agility and responsiveness.

Automation

Mass customization leverages automation technologies to tailor products to individual customer specifications while maintaining high production efficiency. Lights-out manufacturing emphasizes fully automated, unattended production processes enabled by robotics and AI, maximizing operational uptime and minimizing human intervention. Explore the benefits and challenges of integrating automation in these manufacturing strategies to optimize performance and adaptability.

Scalability

Mass customization offers a scalable approach by leveraging flexible manufacturing systems and digital technologies to produce customized products at near mass production speeds. Lights-out manufacturing enhances scalability through fully automated, unmanned production facilities capable of 24/7 operation, reducing human error and operational costs. Explore the nuances of scalability in these manufacturing strategies to optimize your production efficiency.

Source and External Links

Mass Customization: A Complete Guide - Mass customization is a business strategy focused on providing personalized products and services cost-effectively by understanding customer needs, using technology like 3D printing, designing for scalability, automating processes, and monitoring quality and performance.

Guide to Mass Customization - Mass customization combines individuality and mass production advantages, with approaches such as collaborative customization (co-creation) and adaptive customization to best meet customer needs while allowing large-scale production efficiency.

Mass customization - Mass customization leverages flexible computer-aided systems to produce customized products with near mass production efficiency, balancing variety and cost by postponing product differentiation to the latest point in the supply chain and often involving customer-manufacturer collaboration.

dowidth.com

dowidth.com