Closed-loop manufacturing integrates real-time data feedback to continuously monitor and adjust production processes, maximizing efficiency and reducing waste. Agile manufacturing emphasizes flexibility and rapid response to market changes by adapting production lines and workflows quickly to meet customer demands. Explore the key differences and benefits of these manufacturing approaches to optimize your production strategy.

Why it is important

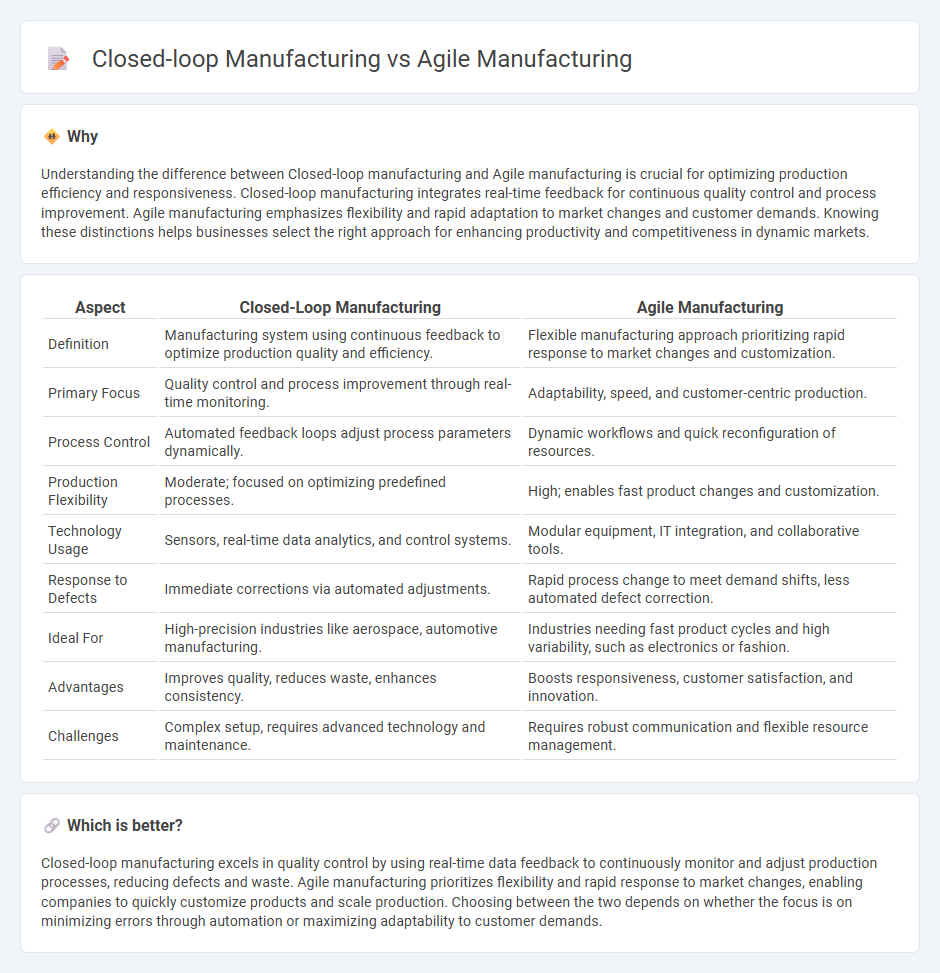

Understanding the difference between Closed-loop manufacturing and Agile manufacturing is crucial for optimizing production efficiency and responsiveness. Closed-loop manufacturing integrates real-time feedback for continuous quality control and process improvement. Agile manufacturing emphasizes flexibility and rapid adaptation to market changes and customer demands. Knowing these distinctions helps businesses select the right approach for enhancing productivity and competitiveness in dynamic markets.

Comparison Table

| Aspect | Closed-Loop Manufacturing | Agile Manufacturing |

|---|---|---|

| Definition | Manufacturing system using continuous feedback to optimize production quality and efficiency. | Flexible manufacturing approach prioritizing rapid response to market changes and customization. |

| Primary Focus | Quality control and process improvement through real-time monitoring. | Adaptability, speed, and customer-centric production. |

| Process Control | Automated feedback loops adjust process parameters dynamically. | Dynamic workflows and quick reconfiguration of resources. |

| Production Flexibility | Moderate; focused on optimizing predefined processes. | High; enables fast product changes and customization. |

| Technology Usage | Sensors, real-time data analytics, and control systems. | Modular equipment, IT integration, and collaborative tools. |

| Response to Defects | Immediate corrections via automated adjustments. | Rapid process change to meet demand shifts, less automated defect correction. |

| Ideal For | High-precision industries like aerospace, automotive manufacturing. | Industries needing fast product cycles and high variability, such as electronics or fashion. |

| Advantages | Improves quality, reduces waste, enhances consistency. | Boosts responsiveness, customer satisfaction, and innovation. |

| Challenges | Complex setup, requires advanced technology and maintenance. | Requires robust communication and flexible resource management. |

Which is better?

Closed-loop manufacturing excels in quality control by using real-time data feedback to continuously monitor and adjust production processes, reducing defects and waste. Agile manufacturing prioritizes flexibility and rapid response to market changes, enabling companies to quickly customize products and scale production. Choosing between the two depends on whether the focus is on minimizing errors through automation or maximizing adaptability to customer demands.

Connection

Closed-loop manufacturing integrates real-time feedback and data analytics to continuously optimize production processes, directly supporting Agile manufacturing's focus on flexibility and rapid responsiveness to market changes. By leveraging sensor data and automated adjustments, closed-loop systems reduce waste and improve quality control, essential for Agile manufacturing's iterative and adaptive workflows. Together, they enable manufacturers to swiftly adapt to customer demands and minimize downtime, enhancing overall operational efficiency and product customization.

Key Terms

Agile Manufacturing:

Agile manufacturing emphasizes flexibility, rapid response to market changes, and efficient production processes by leveraging adaptive technologies and cross-functional teams. It enhances the ability to customize products, reduce lead times, and improve collaboration throughout the supply chain. Discover more about how agile manufacturing drives innovation and operational excellence in modern industries.

Flexibility

Agile manufacturing prioritizes rapid adaptation to market changes through flexible production processes, enabling companies to swiftly modify product designs and volumes. Closed-loop manufacturing integrates real-time feedback systems to continuously optimize and control production quality, emphasizing precision and efficiency while maintaining flexibility. Explore how both approaches enhance manufacturing flexibility by balancing responsiveness and control for optimized production outcomes.

Rapid response

Agile manufacturing emphasizes flexibility and quick adaptation to market changes through decentralized decision-making and lean processes, enabling rapid response to customer demands and production variations. Closed-loop manufacturing integrates real-time data feedback from production and supply chain systems to continuously optimize operations and enhance responsiveness, reducing delays and improving product quality. Explore how these methodologies drive efficiency and speed in modern manufacturing environments.

Source and External Links

What Is Agile Manufacturing? Lean vs. Agile - Agile manufacturing is a methodology focused on rapid response to customers, leveraging speed and flexibility as a competitive advantage by adapting quickly to market demands and using lean principles like small batch production and continuous improvement as its foundation.

Agile manufacturing - Wikipedia - Agile manufacturing is a modern production approach enabling companies to swiftly and flexibly respond to market changes while controlling quality and costs, often integrated with lean manufacturing to balance efficiency and adaptability.

Agile Manufacturing Explained: What, How, and Why -- Katana - Agile manufacturing creates highly flexible production processes that can quickly adjust to changing customer demands or market conditions, improving customer satisfaction, efficiency, competitiveness, and sustainability.

dowidth.com

dowidth.com