Industrial edge computing processes data locally at manufacturing sites, enabling real-time analytics and reducing latency for critical applications like predictive maintenance and quality control. Embedded control systems are dedicated hardware and software units designed to manage specific machinery operations with high reliability and minimal delay. Explore how these technologies enhance efficiency and decision-making in modern manufacturing environments.

Why it is important

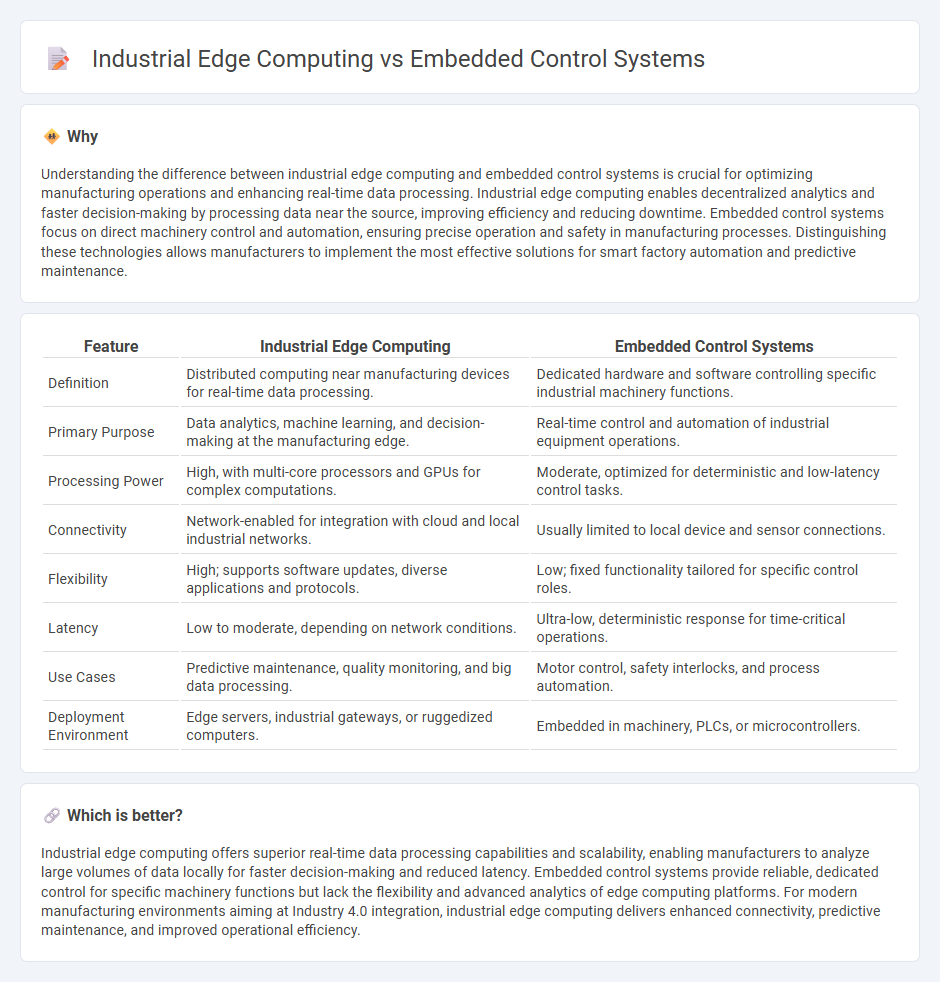

Understanding the difference between industrial edge computing and embedded control systems is crucial for optimizing manufacturing operations and enhancing real-time data processing. Industrial edge computing enables decentralized analytics and faster decision-making by processing data near the source, improving efficiency and reducing downtime. Embedded control systems focus on direct machinery control and automation, ensuring precise operation and safety in manufacturing processes. Distinguishing these technologies allows manufacturers to implement the most effective solutions for smart factory automation and predictive maintenance.

Comparison Table

| Feature | Industrial Edge Computing | Embedded Control Systems |

|---|---|---|

| Definition | Distributed computing near manufacturing devices for real-time data processing. | Dedicated hardware and software controlling specific industrial machinery functions. |

| Primary Purpose | Data analytics, machine learning, and decision-making at the manufacturing edge. | Real-time control and automation of industrial equipment operations. |

| Processing Power | High, with multi-core processors and GPUs for complex computations. | Moderate, optimized for deterministic and low-latency control tasks. |

| Connectivity | Network-enabled for integration with cloud and local industrial networks. | Usually limited to local device and sensor connections. |

| Flexibility | High; supports software updates, diverse applications and protocols. | Low; fixed functionality tailored for specific control roles. |

| Latency | Low to moderate, depending on network conditions. | Ultra-low, deterministic response for time-critical operations. |

| Use Cases | Predictive maintenance, quality monitoring, and big data processing. | Motor control, safety interlocks, and process automation. |

| Deployment Environment | Edge servers, industrial gateways, or ruggedized computers. | Embedded in machinery, PLCs, or microcontrollers. |

Which is better?

Industrial edge computing offers superior real-time data processing capabilities and scalability, enabling manufacturers to analyze large volumes of data locally for faster decision-making and reduced latency. Embedded control systems provide reliable, dedicated control for specific machinery functions but lack the flexibility and advanced analytics of edge computing platforms. For modern manufacturing environments aiming at Industry 4.0 integration, industrial edge computing delivers enhanced connectivity, predictive maintenance, and improved operational efficiency.

Connection

Industrial edge computing enhances manufacturing by processing data locally on embedded control systems, enabling real-time monitoring and rapid decision-making. Embedded control systems act as the interface for machinery and sensors, collecting critical operational data that edge computing analyzes to optimize production efficiency and reduce downtime. This integration boosts automation reliability and supports predictive maintenance, driving smarter industrial operations.

Key Terms

Real-time processing

Embedded control systems offer deterministic real-time processing with minimal latency, essential for safety-critical applications like automotive and aerospace industries. Industrial edge computing provides scalable, distributed processing power closer to the data source, enabling advanced analytics and machine learning while managing real-time constraints through edge-native architectures. Explore how both technologies complement each other to optimize performance in modern industrial environments.

Data analytics

Embedded control systems execute real-time operations with limited processing capabilities, primarily focusing on control logic and sensor data acquisition, thus restricting extensive data analytics applications. Industrial edge computing leverages advanced processing power at the network edge, enabling complex data analytics such as predictive maintenance, anomaly detection, and operational optimization directly on-site. Explore how integrating industrial edge computing enhances data-driven decision-making beyond traditional embedded control systems.

Connectivity

Embedded control systems rely on real-time, low-latency connectivity protocols such as CAN bus or Modbus to ensure precise machine operations and critical data exchange within industrial environments. Industrial edge computing leverages advanced network technologies like 5G and Ethernet/IP to enable high-bandwidth data processing and seamless integration with cloud platforms for enhanced analytics and operational efficiency. Explore how connectivity advancements are transforming industrial automation by delving deeper into the roles and capabilities of embedded control systems and edge computing.

Source and External Links

Embedded system - Wikipedia - An embedded control system is a specialized computer system combining a processor, memory, and I/O peripherals, often using microcontrollers with architectures like simple control loops or interrupt-driven systems designed for low power, small size, and real-time event handling.

A Course in Embedded Control Systems at the University of Michigan - Embedded control systems typically contain microprocessors interfacing with sensors and actuators to perform time-critical operations, often distributed over networks, requiring multi-disciplinary knowledge in control algorithms, real-time software, hardware, and mechanical design.

Achieving Real-Time Performance with Embedded Control Systems - Real-time embedded control systems ensure deterministic, reliable performance in applications like motor control and sensor integration using specialized processors and algorithms to deliver high-speed automated operation.

dowidth.com

dowidth.com