Adaptive machining enhances precision by using real-time sensor feedback to adjust cutting parameters dynamically, reducing errors and material waste. Computer-integrated manufacturing (CIM) streamlines production through automated control of the entire manufacturing process, integrating hardware and software for improved efficiency and reduced lead times. Explore how these advanced technologies transform manufacturing workflows and boost productivity.

Why it is important

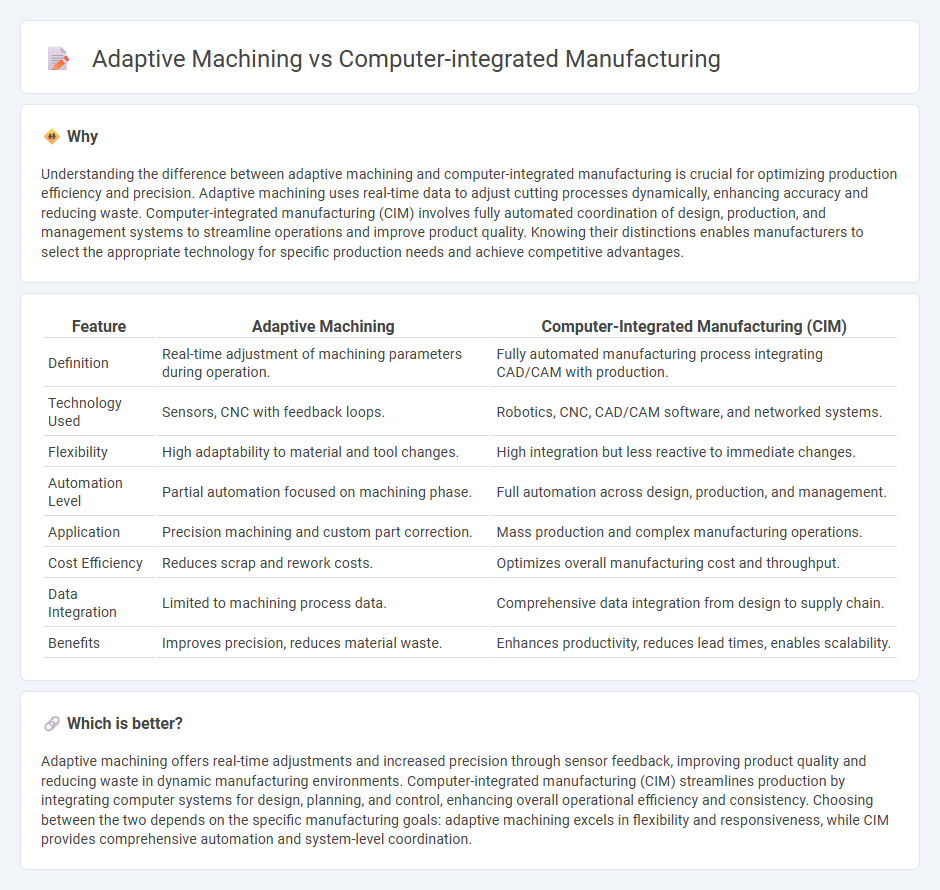

Understanding the difference between adaptive machining and computer-integrated manufacturing is crucial for optimizing production efficiency and precision. Adaptive machining uses real-time data to adjust cutting processes dynamically, enhancing accuracy and reducing waste. Computer-integrated manufacturing (CIM) involves fully automated coordination of design, production, and management systems to streamline operations and improve product quality. Knowing their distinctions enables manufacturers to select the appropriate technology for specific production needs and achieve competitive advantages.

Comparison Table

| Feature | Adaptive Machining | Computer-Integrated Manufacturing (CIM) |

|---|---|---|

| Definition | Real-time adjustment of machining parameters during operation. | Fully automated manufacturing process integrating CAD/CAM with production. |

| Technology Used | Sensors, CNC with feedback loops. | Robotics, CNC, CAD/CAM software, and networked systems. |

| Flexibility | High adaptability to material and tool changes. | High integration but less reactive to immediate changes. |

| Automation Level | Partial automation focused on machining phase. | Full automation across design, production, and management. |

| Application | Precision machining and custom part correction. | Mass production and complex manufacturing operations. |

| Cost Efficiency | Reduces scrap and rework costs. | Optimizes overall manufacturing cost and throughput. |

| Data Integration | Limited to machining process data. | Comprehensive data integration from design to supply chain. |

| Benefits | Improves precision, reduces material waste. | Enhances productivity, reduces lead times, enables scalability. |

Which is better?

Adaptive machining offers real-time adjustments and increased precision through sensor feedback, improving product quality and reducing waste in dynamic manufacturing environments. Computer-integrated manufacturing (CIM) streamlines production by integrating computer systems for design, planning, and control, enhancing overall operational efficiency and consistency. Choosing between the two depends on the specific manufacturing goals: adaptive machining excels in flexibility and responsiveness, while CIM provides comprehensive automation and system-level coordination.

Connection

Adaptive machining relies on real-time data and sensor feedback to adjust machining processes dynamically, enhancing precision and efficiency. Computer-integrated manufacturing (CIM) coordinates various manufacturing processes through computer systems, enabling seamless integration of adaptive machining techniques. Together, adaptive machining and CIM optimize production workflows, reduce errors, and increase automation in modern manufacturing environments.

Key Terms

**Computer-integrated manufacturing:**

Computer-integrated manufacturing (CIM) integrates automated machining, computer-aided design (CAD), and computer-aided manufacturing (CAM) systems to streamline production processes, improve precision, and reduce lead times. CIM systems enhance factory efficiency by enabling real-time monitoring, data exchange, and seamless coordination among different manufacturing stages. Explore more about how CIM revolutionizes modern manufacturing workflows and boosts operational productivity.

Automation

Computer-integrated manufacturing (CIM) streamlines production by integrating automated systems like CAD/CAM, robotics, and real-time data analytics to enhance efficiency and consistency in manufacturing processes. Adaptive machining leverages sensor data and AI to dynamically adjust machining parameters, optimizing tool paths and cutting conditions for improved precision and reduced waste. Explore the advanced automation technologies driving these innovations for deeper insights into their industrial impact.

Integration

Computer-integrated manufacturing (CIM) streamlines production by unifying design, engineering, and manufacturing processes through automated systems, enhancing overall operational efficiency. Adaptive machining employs real-time data and sensor feedback to dynamically adjust machining parameters, optimizing precision and tool performance during production. Explore how these technologies redefine manufacturing integration and adaptability for modern industry demands.

Source and External Links

Computer-integrated manufacturing - Wikipedia - Computer-integrated manufacturing (CIM) is a manufacturing approach using computers to control the entire production process, integrating design, production, marketing, and support functions to enable faster, less error-prone manufacturing with real-time sensor feedback and data exchange between systems.

Computer-Integrated Manufacturing (CIM): Automation & Efficiency - CIM involves key components like CAD/CAM for design and process planning, production control, quality assurance, inventory management, and predictive maintenance to automate and optimize manufacturing operations and improve efficiency, quality, and competitiveness.

Computer Integrated Manufacturing | PPTX - SlideShare - CIM integrates all enterprise operations and manufacturing processes around a common data repository enabling automation, improved efficiency, quality, and responsiveness, although its implementation often requires significant changes in corporate culture and systems.

dowidth.com

dowidth.com