Digital twinning creates a dynamic, real-time virtual replica of physical manufacturing processes, allowing continuous monitoring and operational feedback. Simulation modeling uses static, scenario-based analysis to predict manufacturing outcomes without ongoing data integration. Explore how digital twinning and simulation modeling transform manufacturing efficiency and decision-making.

Why it is important

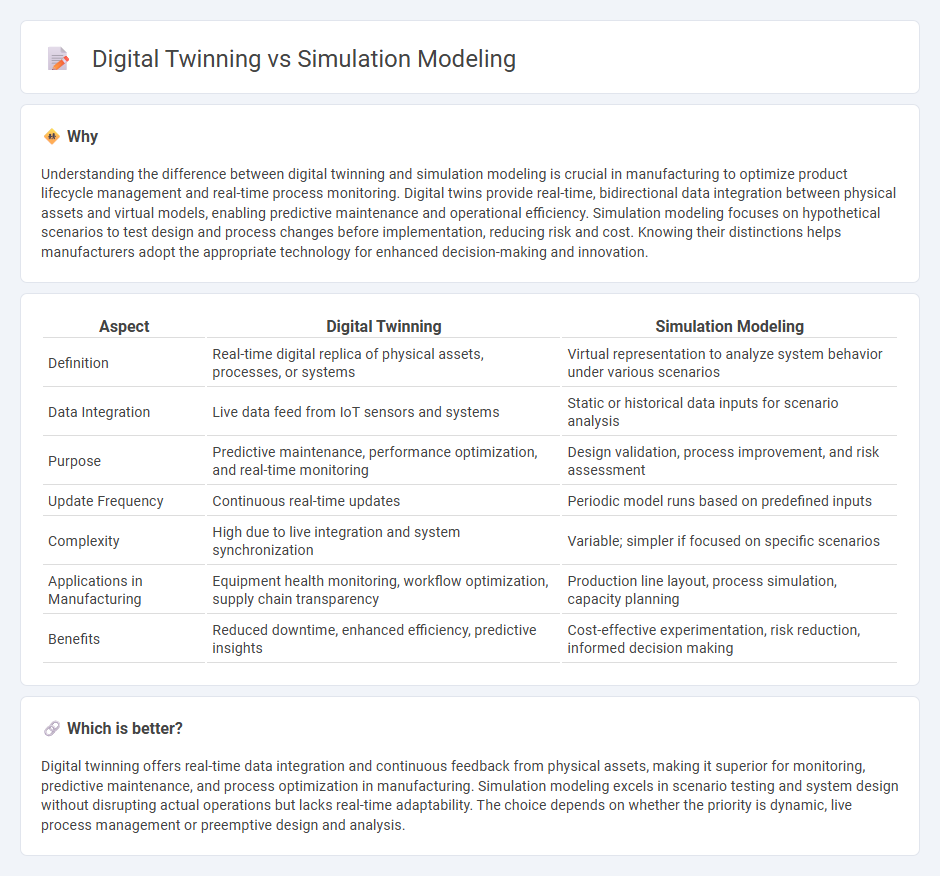

Understanding the difference between digital twinning and simulation modeling is crucial in manufacturing to optimize product lifecycle management and real-time process monitoring. Digital twins provide real-time, bidirectional data integration between physical assets and virtual models, enabling predictive maintenance and operational efficiency. Simulation modeling focuses on hypothetical scenarios to test design and process changes before implementation, reducing risk and cost. Knowing their distinctions helps manufacturers adopt the appropriate technology for enhanced decision-making and innovation.

Comparison Table

| Aspect | Digital Twinning | Simulation Modeling |

|---|---|---|

| Definition | Real-time digital replica of physical assets, processes, or systems | Virtual representation to analyze system behavior under various scenarios |

| Data Integration | Live data feed from IoT sensors and systems | Static or historical data inputs for scenario analysis |

| Purpose | Predictive maintenance, performance optimization, and real-time monitoring | Design validation, process improvement, and risk assessment |

| Update Frequency | Continuous real-time updates | Periodic model runs based on predefined inputs |

| Complexity | High due to live integration and system synchronization | Variable; simpler if focused on specific scenarios |

| Applications in Manufacturing | Equipment health monitoring, workflow optimization, supply chain transparency | Production line layout, process simulation, capacity planning |

| Benefits | Reduced downtime, enhanced efficiency, predictive insights | Cost-effective experimentation, risk reduction, informed decision making |

Which is better?

Digital twinning offers real-time data integration and continuous feedback from physical assets, making it superior for monitoring, predictive maintenance, and process optimization in manufacturing. Simulation modeling excels in scenario testing and system design without disrupting actual operations but lacks real-time adaptability. The choice depends on whether the priority is dynamic, live process management or preemptive design and analysis.

Connection

Digital twinning leverages simulation modeling to create virtual replicas of physical manufacturing processes, enabling real-time monitoring and optimization. Simulation modeling provides predictive analytics within digital twins, allowing manufacturers to test scenarios and improve operational efficiency without disrupting actual production. This integration enhances decision-making by offering detailed insights into machinery performance, process workflows, and potential system failures.

Key Terms

Virtual Prototype

Simulation modeling enables virtual prototypes by using mathematical models to predict system behavior under various conditions, offering insights into performance and feasibility. Digital twinning extends this by creating a dynamic, real-time virtual prototype that mirrors its physical counterpart, facilitating continuous monitoring and optimization. Explore more to understand how these technologies revolutionize product development and operational efficiency.

Real-time Data Integration

Simulation modeling relies on predefined scenarios and historical data to predict system behavior, often lacking continuous real-time updates. Digital twinning integrates real-time data streams from IoT sensors and operational systems, enabling dynamic replication of physical assets for immediate and precise analysis. Explore how digital twins revolutionize strategies through seamless real-time data integration and operational insights.

Predictive Analytics

Simulation modeling enables predictive analytics by creating abstract representations of systems to test scenarios and forecast outcomes based on historical and real-time data. Digital twinning enhances predictive capabilities through real-time synchronization between a physical asset and its digital counterpart, allowing for continuous data-driven insights and proactive decision-making. Explore how integrating these technologies advances predictive analytics for optimized operations.

Source and External Links

Simulation modeling - Wikipedia - Simulation modeling is the process of creating and analyzing a digital prototype of a physical model to predict its real-world performance, helping engineers optimize design, simulate failure, and assess extreme conditions without multiple physical prototypes.

4 types of simulation models used in data analytics - TechTarget - Key types of simulation models include Monte Carlo, Agent-based, Discrete event, and System dynamics, which help analyze and predict behaviors in complex systems for decision-making and risk assessment.

Use of Simulation - AnyLogic - Simulation modeling provides a safe and efficient way to investigate complex systems through computer-based dynamic models, enabling experimentation and insight where physical testing is impractical or costly.

dowidth.com

dowidth.com