Machine vision inspection leverages advanced algorithms and high-resolution cameras to detect defects with greater accuracy and speed compared to manual inspection, which relies on human observation and is prone to variability. Automated systems enhance consistency, reduce labor costs, and facilitate real-time quality control in manufacturing processes. Discover the advantages of integrating machine vision inspection to optimize production quality and efficiency.

Why it is important

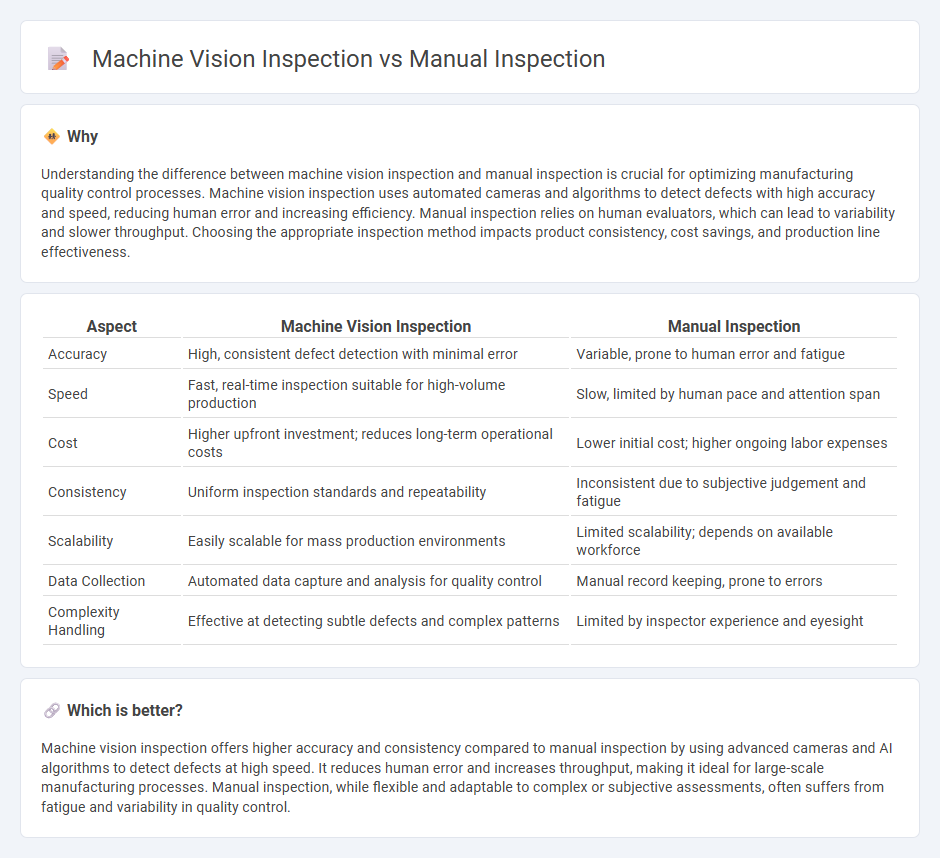

Understanding the difference between machine vision inspection and manual inspection is crucial for optimizing manufacturing quality control processes. Machine vision inspection uses automated cameras and algorithms to detect defects with high accuracy and speed, reducing human error and increasing efficiency. Manual inspection relies on human evaluators, which can lead to variability and slower throughput. Choosing the appropriate inspection method impacts product consistency, cost savings, and production line effectiveness.

Comparison Table

| Aspect | Machine Vision Inspection | Manual Inspection |

|---|---|---|

| Accuracy | High, consistent defect detection with minimal error | Variable, prone to human error and fatigue |

| Speed | Fast, real-time inspection suitable for high-volume production | Slow, limited by human pace and attention span |

| Cost | Higher upfront investment; reduces long-term operational costs | Lower initial cost; higher ongoing labor expenses |

| Consistency | Uniform inspection standards and repeatability | Inconsistent due to subjective judgement and fatigue |

| Scalability | Easily scalable for mass production environments | Limited scalability; depends on available workforce |

| Data Collection | Automated data capture and analysis for quality control | Manual record keeping, prone to errors |

| Complexity Handling | Effective at detecting subtle defects and complex patterns | Limited by inspector experience and eyesight |

Which is better?

Machine vision inspection offers higher accuracy and consistency compared to manual inspection by using advanced cameras and AI algorithms to detect defects at high speed. It reduces human error and increases throughput, making it ideal for large-scale manufacturing processes. Manual inspection, while flexible and adaptable to complex or subjective assessments, often suffers from fatigue and variability in quality control.

Connection

Machine vision inspection and manual inspection in manufacturing are interconnected through their complementary roles in quality control processes. Machine vision systems use automated cameras and AI algorithms to detect defects with high speed and accuracy, while manual inspection relies on human expertise to identify subtle issues and perform detailed evaluations. Integrating both methods ensures comprehensive defect detection, enhances product quality, and reduces the risk of defective goods reaching customers.

Key Terms

Accuracy

Manual inspection relies on human operators to identify defects, often leading to variability in accuracy due to fatigue and subjective judgment. Machine vision inspection utilizes advanced cameras and AI algorithms to consistently detect flaws with high precision and repeatability, significantly reducing false negatives. Explore the latest technologies enhancing inspection accuracy for your industry needs.

Consistency

Machine vision inspection provides superior consistency by eliminating human errors and fatigue that often affect manual inspection accuracy. Automated systems perform high-speed, repeatable evaluations with uniform standards, ensuring reliable quality control across large production volumes. Explore more about how machine vision can transform inspection consistency in your operations.

Throughput

Manual inspection typically results in lower throughput due to human limitations in speed and fatigue, making it less efficient for high-volume production lines. Machine vision inspection significantly increases throughput by enabling rapid, consistent, and non-stop evaluation of products with high accuracy. Discover how integrating advanced machine vision systems can optimize your production throughput.

Source and External Links

Automated Quality Control vs Manual Inspection - Averroes AI - Manual inspection involves human inspectors visually evaluating products for defects, relying on human intuition and adaptability, but it can be slower, subjective, and prone to fatigue compared to automated systems.

Manual Inspection vs. AI Inspection with Instrumental - Manual inspection is commonly used for final visual checks, cosmetic inspection, and safety-critical areas where human judgment is essential despite its limitations in scalability and consistency.

What is Manual Inspection? - Help Center - Manual inspection can also refer to operator-driven test reporting in manufacturing systems where automatic test equipment is absent or inefficient, with data entered through web interfaces for quality control.

dowidth.com

dowidth.com