Machine vision inspection uses advanced cameras and image processing algorithms to detect surface defects with high accuracy and speed, enhancing quality control in manufacturing processes. Magnetic particle inspection employs magnetic fields and ferrous particles to identify surface and near-surface discontinuities in ferromagnetic materials, crucial for ensuring structural integrity. Explore the advantages and applications of both technologies to optimize your inspection strategy.

Why it is important

Understanding the difference between machine vision inspection and magnetic particle inspection is crucial for selecting the appropriate method in manufacturing quality control, as machine vision excels in detecting surface defects using optical technology while magnetic particle inspection identifies surface and near-surface flaws in ferromagnetic materials. Machine vision inspection uses cameras and image processing algorithms to assess product integrity rapidly and non-destructively, ideal for high-speed production lines. Magnetic particle inspection involves applying magnetic fields and ferrous particles to reveal discontinuities, essential for safety-critical components in automotive and aerospace industries. Choosing the right inspection technique enhances defect detection accuracy, ensures compliance with industry standards, and reduces costly recalls.

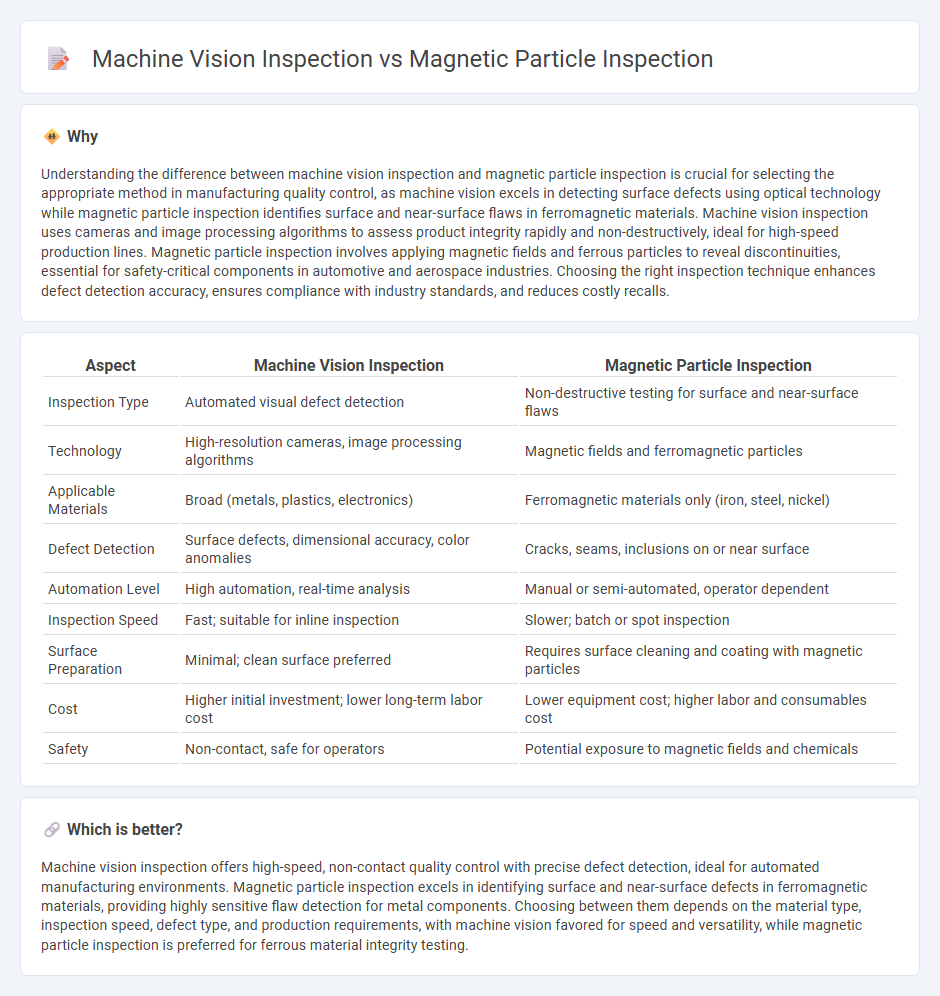

Comparison Table

| Aspect | Machine Vision Inspection | Magnetic Particle Inspection |

|---|---|---|

| Inspection Type | Automated visual defect detection | Non-destructive testing for surface and near-surface flaws |

| Technology | High-resolution cameras, image processing algorithms | Magnetic fields and ferromagnetic particles |

| Applicable Materials | Broad (metals, plastics, electronics) | Ferromagnetic materials only (iron, steel, nickel) |

| Defect Detection | Surface defects, dimensional accuracy, color anomalies | Cracks, seams, inclusions on or near surface |

| Automation Level | High automation, real-time analysis | Manual or semi-automated, operator dependent |

| Inspection Speed | Fast; suitable for inline inspection | Slower; batch or spot inspection |

| Surface Preparation | Minimal; clean surface preferred | Requires surface cleaning and coating with magnetic particles |

| Cost | Higher initial investment; lower long-term labor cost | Lower equipment cost; higher labor and consumables cost |

| Safety | Non-contact, safe for operators | Potential exposure to magnetic fields and chemicals |

Which is better?

Machine vision inspection offers high-speed, non-contact quality control with precise defect detection, ideal for automated manufacturing environments. Magnetic particle inspection excels in identifying surface and near-surface defects in ferromagnetic materials, providing highly sensitive flaw detection for metal components. Choosing between them depends on the material type, inspection speed, defect type, and production requirements, with machine vision favored for speed and versatility, while magnetic particle inspection is preferred for ferrous material integrity testing.

Connection

Machine vision inspection and magnetic particle inspection are connected through their complementary roles in enhancing quality control during manufacturing. Machine vision inspection uses advanced cameras and image processing algorithms to detect surface defects and dimensional inaccuracies, while magnetic particle inspection identifies subsurface flaws in ferromagnetic materials by revealing discontinuities using magnetic fields and iron particles. Combining these technologies ensures comprehensive defect detection, improving product reliability and reducing manufacturing defects.

Key Terms

**Magnetic Particle Inspection:**

Magnetic Particle Inspection (MPI) is a nondestructive testing method that detects surface and near-surface defects in ferromagnetic materials by applying a magnetic field and ferrous particles, which accumulate at discontinuities. MPI is highly effective for identifying cracks, laps, and inclusions in components such as welds, castings, and forgings, offering rapid and reliable defect detection with high sensitivity. Explore more to understand MPI's advantages and applications compared to machine vision inspection.

Ferromagnetic Materials

Magnetic Particle Inspection (MPI) excels in detecting surface and slightly subsurface discontinuities in ferromagnetic materials by using magnetic fields and ferrous particles to reveal defects such as cracks and inclusions. Machine Vision Inspection offers non-contact, high-speed visual analysis capable of identifying surface anomalies, dimensional measurements, and pattern recognition but may struggle with subsurface defect detection in ferromagnetic components. Explore in-depth comparisons and application-specific advantages to optimize your inspection strategy for ferromagnetic materials.

Magnetic Flux Leakage

Magnetic Particle Inspection (MPI) detects surface and near-surface defects in ferromagnetic materials by applying magnetic flux and visualizing leakage fields through magnetic particles, offering high sensitivity for cracks and flaws. Machine Vision Inspection uses cameras and image processing algorithms to analyze surface appearances but lacks direct detection of magnetic flux leakage, limiting its effectiveness in identifying subsurface defects. Explore more about how Magnetic Flux Leakage enhances defect detection beyond visual inspection techniques.

Source and External Links

Magnetic particle inspection - Wikipedia - Magnetic particle inspection (MPI) is a nondestructive testing method that uses a magnetic field to detect surface and near-surface discontinuities in ferromagnetic materials like iron and its alloys by applying magnetic particles that gather at flux leakage areas revealing defects.

How to Do Visible Magnetic Particle Inspections - Magnaflux - This source outlines the standard steps in MPI: magnetizing the part, applying dry magnetic particles during magnetization, inspecting under suitable lighting for indications, and possibly re-magnetizing for additional inspection angles.

Magnetic Particle Testing (MT) Method for NDT Inspections - ASNT - Magnetic particle testing works by introducing a magnetic field into a ferromagnetic part and applying ferrous particles that accumulate at magnetic flux leakages caused by discontinuities, allowing technicians to locate and size surface and near-surface defects.

dowidth.com

dowidth.com