Machine vision enhances manufacturing by enabling real-time quality control through automated defect detection and precise measurements, reducing human error and increasing production efficiency. Predictive maintenance leverages sensor data and machine learning algorithms to forecast equipment failures, minimizing downtime and lowering maintenance costs. Explore how integrating machine vision and predictive maintenance transforms manufacturing processes for optimal performance.

Why it is important

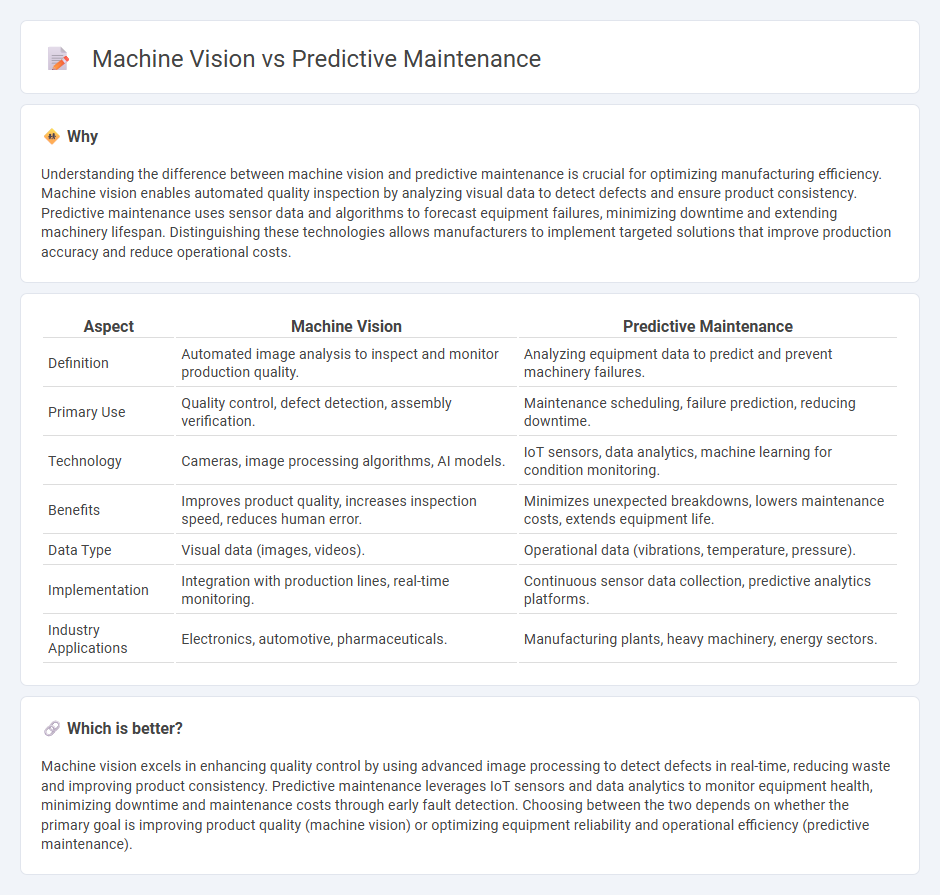

Understanding the difference between machine vision and predictive maintenance is crucial for optimizing manufacturing efficiency. Machine vision enables automated quality inspection by analyzing visual data to detect defects and ensure product consistency. Predictive maintenance uses sensor data and algorithms to forecast equipment failures, minimizing downtime and extending machinery lifespan. Distinguishing these technologies allows manufacturers to implement targeted solutions that improve production accuracy and reduce operational costs.

Comparison Table

| Aspect | Machine Vision | Predictive Maintenance |

|---|---|---|

| Definition | Automated image analysis to inspect and monitor production quality. | Analyzing equipment data to predict and prevent machinery failures. |

| Primary Use | Quality control, defect detection, assembly verification. | Maintenance scheduling, failure prediction, reducing downtime. |

| Technology | Cameras, image processing algorithms, AI models. | IoT sensors, data analytics, machine learning for condition monitoring. |

| Benefits | Improves product quality, increases inspection speed, reduces human error. | Minimizes unexpected breakdowns, lowers maintenance costs, extends equipment life. |

| Data Type | Visual data (images, videos). | Operational data (vibrations, temperature, pressure). |

| Implementation | Integration with production lines, real-time monitoring. | Continuous sensor data collection, predictive analytics platforms. |

| Industry Applications | Electronics, automotive, pharmaceuticals. | Manufacturing plants, heavy machinery, energy sectors. |

Which is better?

Machine vision excels in enhancing quality control by using advanced image processing to detect defects in real-time, reducing waste and improving product consistency. Predictive maintenance leverages IoT sensors and data analytics to monitor equipment health, minimizing downtime and maintenance costs through early fault detection. Choosing between the two depends on whether the primary goal is improving product quality (machine vision) or optimizing equipment reliability and operational efficiency (predictive maintenance).

Connection

Machine vision systems capture real-time data on equipment conditions, enabling precise monitoring of manufacturing processes. This data feeds into predictive maintenance algorithms, which analyze patterns to forecast potential machine failures. Integrating machine vision with predictive maintenance reduces downtime, enhances operational efficiency, and lowers maintenance costs in manufacturing environments.

Key Terms

**Predictive maintenance:**

Predictive maintenance leverages advanced analytics and sensor data to anticipate equipment failures, reducing downtime and maintenance costs while enhancing operational efficiency. It employs techniques such as vibration analysis, thermal imaging, and IoT connectivity to monitor asset health in real-time. Discover how integrating predictive maintenance can transform your maintenance strategy and boost productivity.

Condition monitoring

Predictive maintenance leverages sensor data and advanced algorithms to anticipate equipment failures by analyzing patterns and anomalies in real-time operational parameters. Machine vision enhances condition monitoring by providing visual inspections and defect detection through image processing and AI-driven analysis, enabling early identification of surface-level faults. Explore the latest advancements in integrating predictive maintenance with machine vision for comprehensive condition monitoring.

Failure prediction

Predictive maintenance leverages advanced sensors and data analytics to anticipate equipment failures by monitoring real-time operational parameters, enabling timely interventions that minimize downtime. Machine vision enhances failure prediction by utilizing high-resolution cameras and AI algorithms to detect surface defects and anomalies that traditional sensors might miss. Explore how integrating these technologies can revolutionize failure prediction strategies in industrial settings.

Source and External Links

What is Predictive Maintenance? - Predictive maintenance uses sensor data and advanced analytics like machine learning to continuously assess equipment health and predict when maintenance should be performed, reducing unplanned downtime and maintenance costs by acting only when necessary.

Predictive maintenance - Predictive maintenance determines equipment condition to schedule maintenance based on actual state rather than average life, enabling planned stops, cost savings, longer equipment life, and better resource use.

What is Predictive Maintenance? Benefits, Challenges & ... - Predictive maintenance leverages real-time data and analytics to forecast equipment failures early, optimize maintenance timing, reduce costs, improve asset lifespan, and enhance safety, particularly in fleet management.

dowidth.com

dowidth.com