Soft robotics and collaborative robots (cobots) represent innovative advancements in manufacturing automation, enhancing flexibility and safety on the production floor. Soft robotics utilize flexible materials to perform delicate tasks and adapt to complex environments, while cobots are designed to work safely alongside human operators, improving efficiency through shared tasks. Explore these technologies further to understand their unique applications and benefits in modern manufacturing processes.

Why it is important

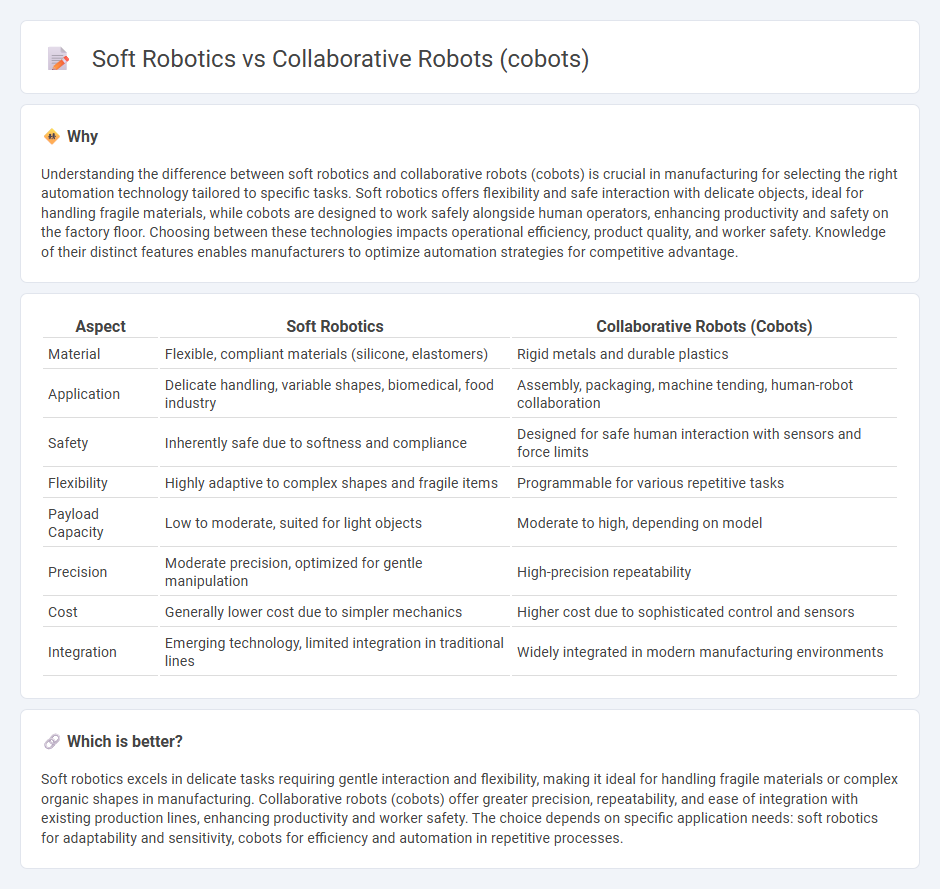

Understanding the difference between soft robotics and collaborative robots (cobots) is crucial in manufacturing for selecting the right automation technology tailored to specific tasks. Soft robotics offers flexibility and safe interaction with delicate objects, ideal for handling fragile materials, while cobots are designed to work safely alongside human operators, enhancing productivity and safety on the factory floor. Choosing between these technologies impacts operational efficiency, product quality, and worker safety. Knowledge of their distinct features enables manufacturers to optimize automation strategies for competitive advantage.

Comparison Table

| Aspect | Soft Robotics | Collaborative Robots (Cobots) |

|---|---|---|

| Material | Flexible, compliant materials (silicone, elastomers) | Rigid metals and durable plastics |

| Application | Delicate handling, variable shapes, biomedical, food industry | Assembly, packaging, machine tending, human-robot collaboration |

| Safety | Inherently safe due to softness and compliance | Designed for safe human interaction with sensors and force limits |

| Flexibility | Highly adaptive to complex shapes and fragile items | Programmable for various repetitive tasks |

| Payload Capacity | Low to moderate, suited for light objects | Moderate to high, depending on model |

| Precision | Moderate precision, optimized for gentle manipulation | High-precision repeatability |

| Cost | Generally lower cost due to simpler mechanics | Higher cost due to sophisticated control and sensors |

| Integration | Emerging technology, limited integration in traditional lines | Widely integrated in modern manufacturing environments |

Which is better?

Soft robotics excels in delicate tasks requiring gentle interaction and flexibility, making it ideal for handling fragile materials or complex organic shapes in manufacturing. Collaborative robots (cobots) offer greater precision, repeatability, and ease of integration with existing production lines, enhancing productivity and worker safety. The choice depends on specific application needs: soft robotics for adaptability and sensitivity, cobots for efficiency and automation in repetitive processes.

Connection

Soft robotics and collaborative robots (cobots) are interconnected through their shared emphasis on flexibility and safe human-robot interaction in manufacturing environments. Soft robotics utilize pliable materials and adaptive mechanisms to handle delicate tasks, while cobots are designed to work alongside human operators without safety barriers. Integrating soft robotic components into cobots enhances their dexterity and sensitivity, enabling more precise, efficient, and collaborative manufacturing processes.

Key Terms

Human-robot interaction

Collaborative robots (cobots) are designed to work safely alongside humans in shared environments, emphasizing ergonomic design and sensor-based safety features that enable real-time interaction. Soft robotics leverage flexible, compliant materials to mimic natural movements, enhancing dexterity and adaptability in complex tasks while minimizing risk of injury. Explore the latest advancements in human-robot interaction to understand how these technologies are revolutionizing collaborative automation.

Flexibility

Collaborative robots (cobots) excel in precision and repeatability within structured industrial environments, offering flexible automation solutions adaptable to various manufacturing tasks. Soft robotics, characterized by their compliant materials and adaptive structures, provide unparalleled flexibility for handling delicate objects and navigating unstructured settings. Explore deeper insights into how cobots and soft robots redefine flexibility across industries.

Dexterity

Collaborative robots (cobots) excel in precision and repeatability, offering advanced dexterity in controlled industrial settings through articulated joints and multi-axis movement. Soft robotics leverage flexible, adaptive materials that mimic biological systems, enabling delicate handling and versatile manipulation in unstructured environments. Explore the evolving capabilities of dexterity in cobots and soft robotics to understand their distinct applications and future potential.

Source and External Links

The True Value of Collaborative Robots (Cobots) - AutoStore - Cobots are designed to work safely alongside humans in shared workspaces, offering flexibility and advanced safety features for tasks like assembly, material handling, and precision operations.

What is a cobot? | The ultimate collaborative robot guide - Cobots are advanced, sensor-equipped robots that can safely collaborate with people, democratizing automation for companies of all sizes and enabling quick adaptation to changing production needs.

Cobots: A beginner's guide to collaborative robots - Standard Bots - Cobots are defined by their ability to work directly with humans without safety barriers and come in types such as power- and force-limiting, safety-monitored stop, speed and separation monitoring, and hand-guiding, depending on their safety mechanisms and applications.

dowidth.com

dowidth.com