Hyperautomation integrates advanced AI technologies to streamline manufacturing processes, boosting productivity and reducing errors through end-to-end automation. Machine vision focuses specifically on visual inspection and quality control by enabling machines to interpret and analyze images with high precision. Discover how these transformative technologies are reshaping manufacturing efficiency and accuracy.

Why it is important

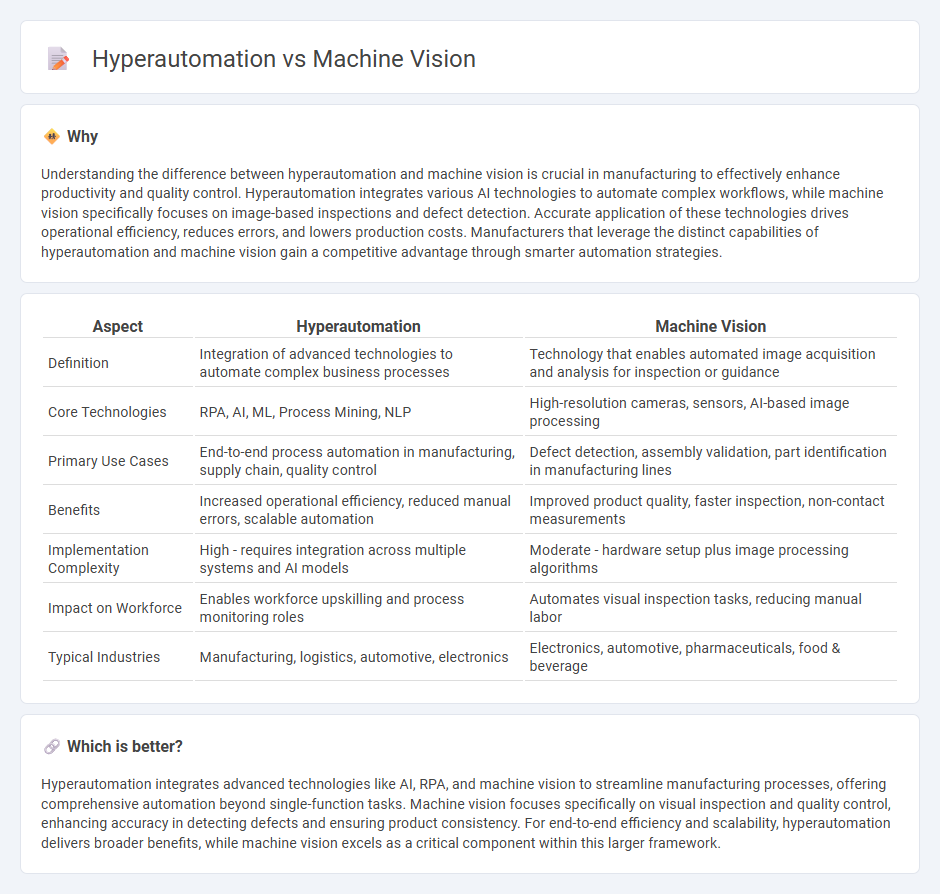

Understanding the difference between hyperautomation and machine vision is crucial in manufacturing to effectively enhance productivity and quality control. Hyperautomation integrates various AI technologies to automate complex workflows, while machine vision specifically focuses on image-based inspections and defect detection. Accurate application of these technologies drives operational efficiency, reduces errors, and lowers production costs. Manufacturers that leverage the distinct capabilities of hyperautomation and machine vision gain a competitive advantage through smarter automation strategies.

Comparison Table

| Aspect | Hyperautomation | Machine Vision |

|---|---|---|

| Definition | Integration of advanced technologies to automate complex business processes | Technology that enables automated image acquisition and analysis for inspection or guidance |

| Core Technologies | RPA, AI, ML, Process Mining, NLP | High-resolution cameras, sensors, AI-based image processing |

| Primary Use Cases | End-to-end process automation in manufacturing, supply chain, quality control | Defect detection, assembly validation, part identification in manufacturing lines |

| Benefits | Increased operational efficiency, reduced manual errors, scalable automation | Improved product quality, faster inspection, non-contact measurements |

| Implementation Complexity | High - requires integration across multiple systems and AI models | Moderate - hardware setup plus image processing algorithms |

| Impact on Workforce | Enables workforce upskilling and process monitoring roles | Automates visual inspection tasks, reducing manual labor |

| Typical Industries | Manufacturing, logistics, automotive, electronics | Electronics, automotive, pharmaceuticals, food & beverage |

Which is better?

Hyperautomation integrates advanced technologies like AI, RPA, and machine vision to streamline manufacturing processes, offering comprehensive automation beyond single-function tasks. Machine vision focuses specifically on visual inspection and quality control, enhancing accuracy in detecting defects and ensuring product consistency. For end-to-end efficiency and scalability, hyperautomation delivers broader benefits, while machine vision excels as a critical component within this larger framework.

Connection

Hyperautomation integrates machine vision to enhance manufacturing processes by enabling real-time quality inspections and defect detection with high precision and speed. Machine vision systems capture and analyze visual data, which hyperautomation platforms use to streamline production workflows and reduce human error. This synergy accelerates decision-making, improves operational efficiency, and supports predictive maintenance in manufacturing environments.

Key Terms

**Machine Vision:**

Machine vision involves the use of cameras, sensors, and AI algorithms to enable machines to interpret and act on visual data with high accuracy and speed, essential in quality control, defect detection, and robotic guidance. It focuses on real-time image processing and machine learning techniques to extract meaningful information from visual inputs, significantly improving automation in manufacturing and logistics. Explore the latest advancements in machine vision technology to enhance operational efficiency and product quality.

Image Processing

Machine vision leverages advanced cameras and sensors to capture and analyze images for quality control, defect detection, and pattern recognition in industrial automation. Hyperautomation integrates machine vision with AI-driven workflows and robotic process automation to streamline complex business processes, enhancing decision-making and operational efficiency. Explore how combining image processing with hyperautomation transforms industries by driving intelligent automation solutions.

Pattern Recognition

Machine vision leverages advanced cameras and AI algorithms to perform precise pattern recognition, enabling real-time defect detection and quality control in manufacturing. Hyperautomation integrates machine vision with process automation tools, orchestrating end-to-end workflows that enhance operational efficiency beyond isolated visual inspections. Explore the distinct benefits and applications of machine vision and hyperautomation in pattern recognition to optimize industrial processes.

Source and External Links

What Is Machine Vision? - Intel - Machine vision combines smart cameras, industrial PCs, and deep learning to enable robots and automated systems to perceive and make decisions in industrial automation, distinct from broader computer vision by focusing on predefined tasks like quality inspection and robotic guidance.

Machine Vision Vs Computer Vision - What Is The Difference? | Zebra - Machine vision is a focused subset of computer vision used in industrial practical applications such as inspecting objects, detecting flaws, and robot guidance by capturing images and triggering automated actions.

What is Machine Vision? | Definition from TechTarget - Machine vision uses cameras, image processing, and AI to allow computers and robots to see and perform complex tasks like picking, sorting, scanning, and navigating environments in manufacturing and retail.

dowidth.com

dowidth.com