Digital thread integrates real-time data flow across the entire manufacturing lifecycle, enhancing traceability and decision-making. Six Sigma focuses on reducing defects and variability through rigorous statistical analysis and continuous improvement methodologies. Discover how combining digital thread with Six Sigma can revolutionize manufacturing efficiency and quality control.

Why it is important

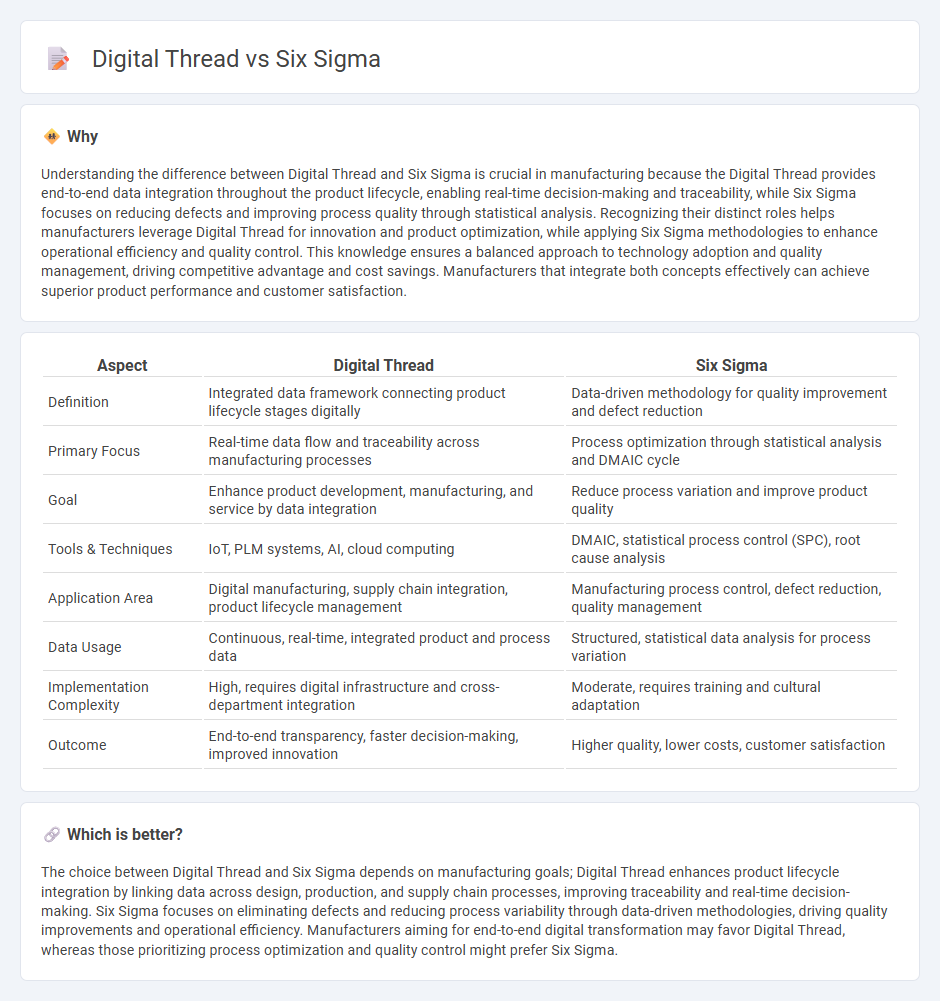

Understanding the difference between Digital Thread and Six Sigma is crucial in manufacturing because the Digital Thread provides end-to-end data integration throughout the product lifecycle, enabling real-time decision-making and traceability, while Six Sigma focuses on reducing defects and improving process quality through statistical analysis. Recognizing their distinct roles helps manufacturers leverage Digital Thread for innovation and product optimization, while applying Six Sigma methodologies to enhance operational efficiency and quality control. This knowledge ensures a balanced approach to technology adoption and quality management, driving competitive advantage and cost savings. Manufacturers that integrate both concepts effectively can achieve superior product performance and customer satisfaction.

Comparison Table

| Aspect | Digital Thread | Six Sigma |

|---|---|---|

| Definition | Integrated data framework connecting product lifecycle stages digitally | Data-driven methodology for quality improvement and defect reduction |

| Primary Focus | Real-time data flow and traceability across manufacturing processes | Process optimization through statistical analysis and DMAIC cycle |

| Goal | Enhance product development, manufacturing, and service by data integration | Reduce process variation and improve product quality |

| Tools & Techniques | IoT, PLM systems, AI, cloud computing | DMAIC, statistical process control (SPC), root cause analysis |

| Application Area | Digital manufacturing, supply chain integration, product lifecycle management | Manufacturing process control, defect reduction, quality management |

| Data Usage | Continuous, real-time, integrated product and process data | Structured, statistical data analysis for process variation |

| Implementation Complexity | High, requires digital infrastructure and cross-department integration | Moderate, requires training and cultural adaptation |

| Outcome | End-to-end transparency, faster decision-making, improved innovation | Higher quality, lower costs, customer satisfaction |

Which is better?

The choice between Digital Thread and Six Sigma depends on manufacturing goals; Digital Thread enhances product lifecycle integration by linking data across design, production, and supply chain processes, improving traceability and real-time decision-making. Six Sigma focuses on eliminating defects and reducing process variability through data-driven methodologies, driving quality improvements and operational efficiency. Manufacturers aiming for end-to-end digital transformation may favor Digital Thread, whereas those prioritizing process optimization and quality control might prefer Six Sigma.

Connection

Digital thread integrates real-time data across manufacturing processes, enabling precise monitoring and control that supports Six Sigma's focus on reducing defects and variability. Six Sigma methodologies leverage this continuous data flow to identify root causes and implement improvements, enhancing process efficiency and product quality. The synergy between digital thread and Six Sigma drives data-driven decision-making, fostering consistent production excellence and minimizing operational costs.

Key Terms

Defect Reduction (Six Sigma)

Six Sigma employs statistical methods and DMAIC (Define, Measure, Analyze, Improve, Control) to achieve defect reduction by minimizing process variation and improving quality control. The digital thread integrates real-time data across the product lifecycle, enabling enhanced traceability and proactive defect identification through advanced analytics and IoT connectivity. Explore how combining Six Sigma's structured defect reduction with digital thread innovations can elevate manufacturing quality and efficiency.

Data Integration (Digital Thread)

Digital thread technology seamlessly integrates data across the entire product lifecycle, enabling real-time visibility and traceability from design to manufacturing and beyond. Six Sigma focuses on process improvement and quality management by reducing variability and defects through data-driven methodologies. Explore how integrating Six Sigma principles with digital thread capabilities can drive superior data integration and operational excellence.

Process Optimization (Both)

Six Sigma utilizes data-driven methodologies and statistical analysis to reduce process variation and defects, achieving near-perfect quality levels in manufacturing and business operations. Digital thread integrates real-time data and interconnected digital models across the product lifecycle, enabling seamless process optimization and enhanced decision-making through continuous feedback loops. Explore how combining Six Sigma with digital thread technologies elevates process efficiency and innovation.

Source and External Links

What is Lean Six Sigma? - ASQ - Six Sigma is a disciplined quality improvement method focused on reducing process variation and defects to improve customer satisfaction, aiming for a defect level of 3.4 per million opportunities by defining, measuring, analyzing, improving, and controlling business processes.

Six Sigma - Wikipedia - Introduced by Bill Smith at Motorola in 1986, Six Sigma relies on data-driven approaches and statistical methods to reduce defects and variability in manufacturing and business processes, emphasizing management commitment and measurable financial returns.

What Is Six Sigma?: Transform Your Organization's Productivity - Six Sigma requires structured implementation with defined roles such as White, Yellow, Green, Black, and Master Black Belts, involving leadership engagement and team-driven projects to systematically eliminate defects and improve processes.

dowidth.com

dowidth.com