Industrial Internet integrates advanced data analytics, IoT sensors, and cloud computing to optimize manufacturing processes in real-time, driving predictive maintenance and enhanced operational efficiency. SCADA systems focus on centralized monitoring and control of industrial equipment through programmable logic controllers and human-machine interfaces, ensuring reliable automation and safety. Explore the key differences and benefits of Industrial Internet versus SCADA to transform your manufacturing operations.

Why it is important

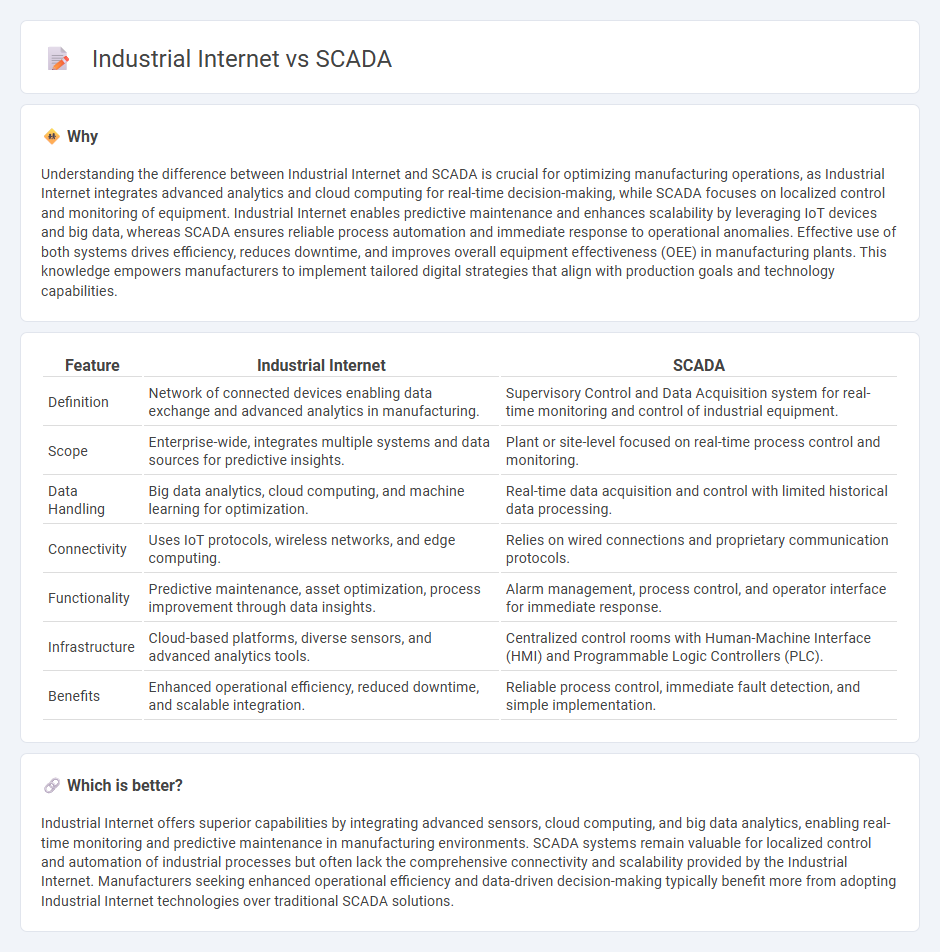

Understanding the difference between Industrial Internet and SCADA is crucial for optimizing manufacturing operations, as Industrial Internet integrates advanced analytics and cloud computing for real-time decision-making, while SCADA focuses on localized control and monitoring of equipment. Industrial Internet enables predictive maintenance and enhances scalability by leveraging IoT devices and big data, whereas SCADA ensures reliable process automation and immediate response to operational anomalies. Effective use of both systems drives efficiency, reduces downtime, and improves overall equipment effectiveness (OEE) in manufacturing plants. This knowledge empowers manufacturers to implement tailored digital strategies that align with production goals and technology capabilities.

Comparison Table

| Feature | Industrial Internet | SCADA |

|---|---|---|

| Definition | Network of connected devices enabling data exchange and advanced analytics in manufacturing. | Supervisory Control and Data Acquisition system for real-time monitoring and control of industrial equipment. |

| Scope | Enterprise-wide, integrates multiple systems and data sources for predictive insights. | Plant or site-level focused on real-time process control and monitoring. |

| Data Handling | Big data analytics, cloud computing, and machine learning for optimization. | Real-time data acquisition and control with limited historical data processing. |

| Connectivity | Uses IoT protocols, wireless networks, and edge computing. | Relies on wired connections and proprietary communication protocols. |

| Functionality | Predictive maintenance, asset optimization, process improvement through data insights. | Alarm management, process control, and operator interface for immediate response. |

| Infrastructure | Cloud-based platforms, diverse sensors, and advanced analytics tools. | Centralized control rooms with Human-Machine Interface (HMI) and Programmable Logic Controllers (PLC). |

| Benefits | Enhanced operational efficiency, reduced downtime, and scalable integration. | Reliable process control, immediate fault detection, and simple implementation. |

Which is better?

Industrial Internet offers superior capabilities by integrating advanced sensors, cloud computing, and big data analytics, enabling real-time monitoring and predictive maintenance in manufacturing environments. SCADA systems remain valuable for localized control and automation of industrial processes but often lack the comprehensive connectivity and scalability provided by the Industrial Internet. Manufacturers seeking enhanced operational efficiency and data-driven decision-making typically benefit more from adopting Industrial Internet technologies over traditional SCADA solutions.

Connection

The Industrial Internet integrates IoT devices with manufacturing processes, enabling real-time data collection and analytics to optimize production efficiency. SCADA systems serve as the backbone for monitoring and controlling these industrial processes, providing centralized visualization and automated control within smart factories. Together, they enhance predictive maintenance, reduce downtime, and improve supply chain management by creating interconnected digital manufacturing environments.

Key Terms

Real-time Monitoring

SCADA (Supervisory Control and Data Acquisition) systems enable real-time monitoring by collecting data from sensors and controlling industrial processes to optimize efficiency and safety. Industrial Internet, or Industrial Internet of Things (IIoT), enhances real-time monitoring by integrating advanced analytics, cloud computing, and machine learning for predictive maintenance and improved operational insights. Discover how combining SCADA with Industrial Internet technologies revolutionizes real-time industrial monitoring.

Data Integration

SCADA systems primarily collect and monitor real-time data from industrial processes, while Industrial Internet solutions integrate diverse data sources, including SCADA, IoT devices, and enterprise systems, for comprehensive analytics and decision-making. Industrial Internet platforms enhance data integration by enabling interoperability, scalability, and advanced data processing across multiple layers of an industrial ecosystem. Explore how integrating SCADA with Industrial Internet technologies can optimize operational efficiency and drive innovation in industrial environments.

Automation

SCADA systems provide real-time monitoring and control of industrial processes, ensuring operational efficiency and safety through centralized data acquisition and supervisory control. The Industrial Internet leverages advanced IoT connectivity, big data analytics, and cloud computing to enable predictive maintenance, enhanced automation, and improved decision-making across distributed industrial assets. Explore the evolving landscape of automation by discovering the distinct roles of SCADA and Industrial Internet technologies.

Source and External Links

What is SCADA? - Supervisory Control and Data Acquisition - SCADA is a system that allows organizations to control and monitor industrial processes through software and hardware elements, enhancing efficiency and decision-making.

SCADA - Wikipedia - SCADA systems are used for high-level supervision of machines and processes, involving computers, networked communications, and user interfaces.

SCADA Systems: What They Are & How They Work - Splunk - SCADA systems help organizations control, monitor, and analyze industrial devices and processes, using sensors, actuators, and networked communications.

dowidth.com

dowidth.com