Generative design leverages advanced algorithms and artificial intelligence to create optimized product models by exploring numerous design variations, focusing on innovation and performance enhancement. Design for manufacturability (DFM) emphasizes simplifying and adapting designs to facilitate efficient, cost-effective production processes while ensuring quality and reliability. Explore the key differences and benefits of generative design versus DFM to enhance your manufacturing strategy.

Why it is important

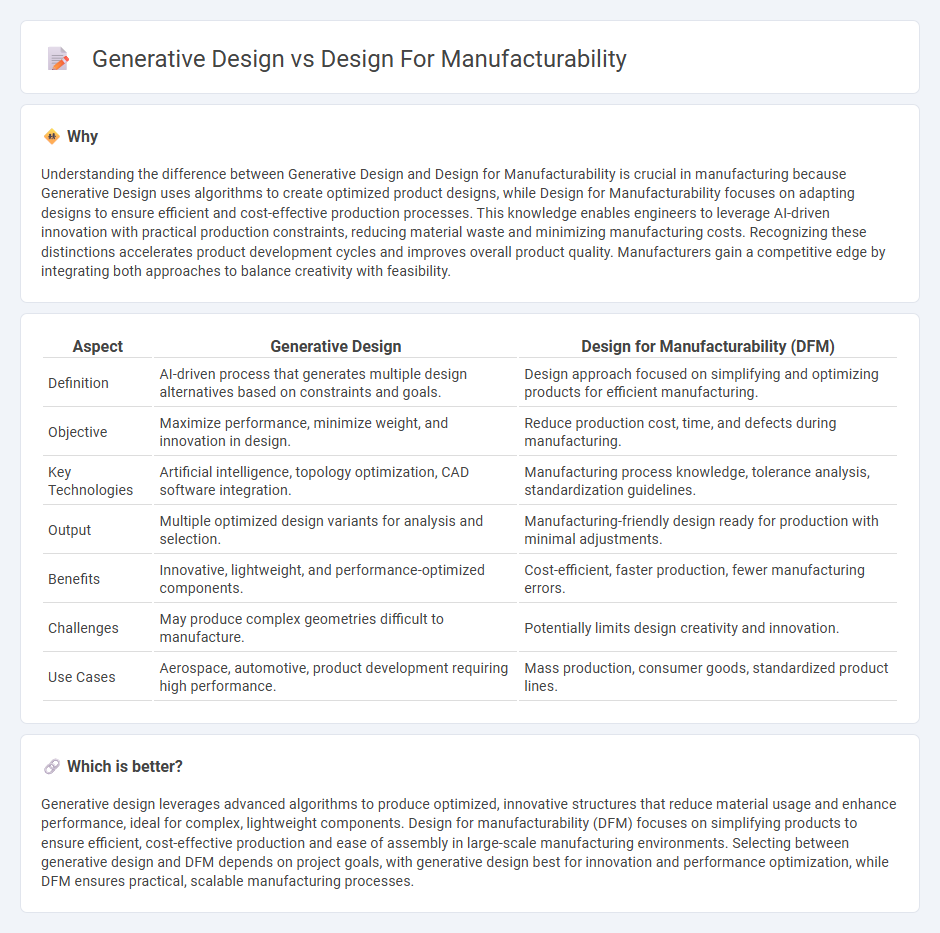

Understanding the difference between Generative Design and Design for Manufacturability is crucial in manufacturing because Generative Design uses algorithms to create optimized product designs, while Design for Manufacturability focuses on adapting designs to ensure efficient and cost-effective production processes. This knowledge enables engineers to leverage AI-driven innovation with practical production constraints, reducing material waste and minimizing manufacturing costs. Recognizing these distinctions accelerates product development cycles and improves overall product quality. Manufacturers gain a competitive edge by integrating both approaches to balance creativity with feasibility.

Comparison Table

| Aspect | Generative Design | Design for Manufacturability (DFM) |

|---|---|---|

| Definition | AI-driven process that generates multiple design alternatives based on constraints and goals. | Design approach focused on simplifying and optimizing products for efficient manufacturing. |

| Objective | Maximize performance, minimize weight, and innovation in design. | Reduce production cost, time, and defects during manufacturing. |

| Key Technologies | Artificial intelligence, topology optimization, CAD software integration. | Manufacturing process knowledge, tolerance analysis, standardization guidelines. |

| Output | Multiple optimized design variants for analysis and selection. | Manufacturing-friendly design ready for production with minimal adjustments. |

| Benefits | Innovative, lightweight, and performance-optimized components. | Cost-efficient, faster production, fewer manufacturing errors. |

| Challenges | May produce complex geometries difficult to manufacture. | Potentially limits design creativity and innovation. |

| Use Cases | Aerospace, automotive, product development requiring high performance. | Mass production, consumer goods, standardized product lines. |

Which is better?

Generative design leverages advanced algorithms to produce optimized, innovative structures that reduce material usage and enhance performance, ideal for complex, lightweight components. Design for manufacturability (DFM) focuses on simplifying products to ensure efficient, cost-effective production and ease of assembly in large-scale manufacturing environments. Selecting between generative design and DFM depends on project goals, with generative design best for innovation and performance optimization, while DFM ensures practical, scalable manufacturing processes.

Connection

Generative design leverages artificial intelligence algorithms to create optimized product models by exploring countless design permutations, directly aligning with Design for Manufacturability (DFM) principles that emphasize ease of production and cost efficiency. By integrating generative design outputs with DFM guidelines, manufacturers can reduce material waste, minimize production time, and enhance overall product performance. This synergy accelerates innovation cycles while ensuring that complex designs remain practical for mass production using current manufacturing technologies like CNC machining and additive manufacturing.

Key Terms

Design constraints

Design for manufacturability (DFM) emphasizes imposing strict design constraints early to ensure products can be efficiently and cost-effectively produced using existing manufacturing processes. Generative design leverages algorithms to explore a vast design space, often pushing traditional constraints to innovate forms optimized for performance, weight, and material usage. Explore how balancing design constraints in DFM and generative design drives innovation and production efficiency.

Production efficiency

Design for manufacturability (DFM) emphasizes simplifying product designs to reduce production costs and minimize manufacturing complexities, enhancing overall efficiency on the assembly line. Generative design uses AI algorithms to explore numerous design permutations, optimizing structures for weight, strength, and material use while often requiring advanced manufacturing techniques like 3D printing. Explore how integrating DFM principles with generative design can revolutionize production workflows and improve manufacturing efficiency.

Algorithm-driven optimization

Algorithm-driven optimization in design for manufacturability (DFM) prioritizes simplifying production processes to reduce costs and enhance efficiency by integrating manufacturing constraints directly into the design phase. Generative design employs advanced algorithms and artificial intelligence to explore vast design possibilities, optimizing for performance, material usage, and manufacturing feasibility simultaneously. Explore how these algorithmic approaches transform product development by balancing innovation with practical manufacturing.

Source and External Links

Design for manufacturability - Wikipedia - Design for manufacturability (DFM) is an engineering practice to design products that are easy and cost-effective to manufacture by addressing potential production issues early in the design phase, with guidelines tailored to specific processes and materials.

A Guide to Design-for-Manufacturing (DFM) Principles - DFM includes principles such as manufacturability, assembly, reliability, testing, and serviceability, aiming to simplify product design and assembly to reduce costs and improve product performance and maintenance.

Design for Manufacturing (DFM): A Guide to Optimizing ... - Six Sigma - DFM integrates manufacturing considerations from initial design stages, focusing on material selection, assembly optimization, and quality control to reduce costs and enhance product quality throughout the production lifecycle.

dowidth.com

dowidth.com