Servitization transforms traditional manufacturing by integrating services with products to enhance customer value, contrasting sharply with mass production's focus on high-volume, standardized output. This shift enables businesses to create tailored solutions, improve customer loyalty, and generate recurring revenue streams. Explore the key differences and benefits of servitization versus mass production to understand which strategy drives competitive advantage in modern manufacturing.

Why it is important

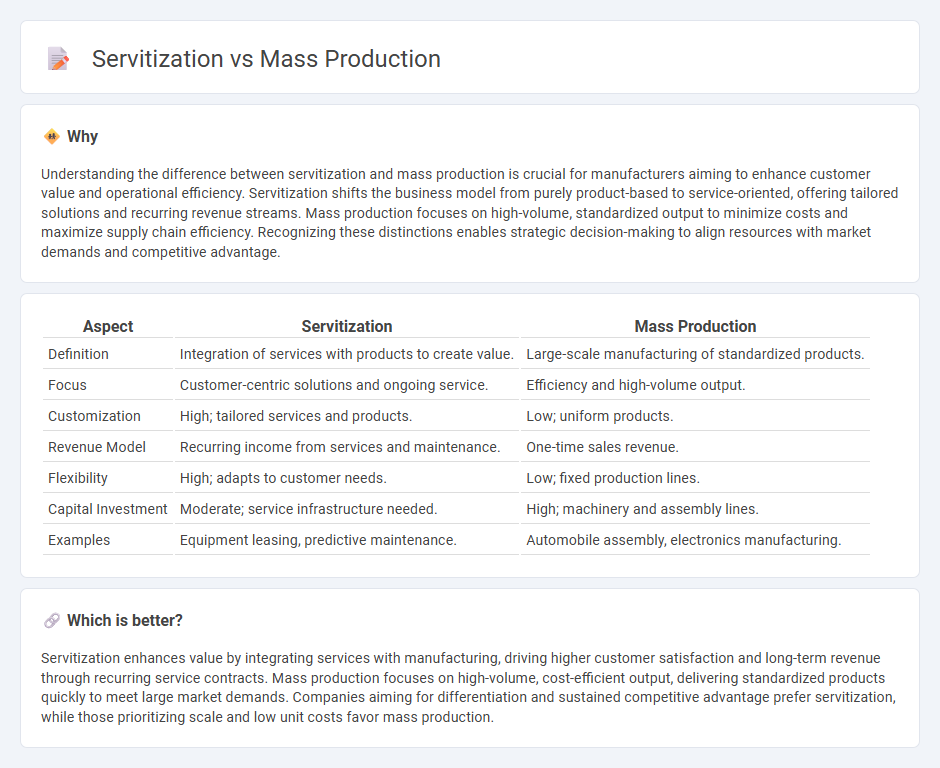

Understanding the difference between servitization and mass production is crucial for manufacturers aiming to enhance customer value and operational efficiency. Servitization shifts the business model from purely product-based to service-oriented, offering tailored solutions and recurring revenue streams. Mass production focuses on high-volume, standardized output to minimize costs and maximize supply chain efficiency. Recognizing these distinctions enables strategic decision-making to align resources with market demands and competitive advantage.

Comparison Table

| Aspect | Servitization | Mass Production |

|---|---|---|

| Definition | Integration of services with products to create value. | Large-scale manufacturing of standardized products. |

| Focus | Customer-centric solutions and ongoing service. | Efficiency and high-volume output. |

| Customization | High; tailored services and products. | Low; uniform products. |

| Revenue Model | Recurring income from services and maintenance. | One-time sales revenue. |

| Flexibility | High; adapts to customer needs. | Low; fixed production lines. |

| Capital Investment | Moderate; service infrastructure needed. | High; machinery and assembly lines. |

| Examples | Equipment leasing, predictive maintenance. | Automobile assembly, electronics manufacturing. |

Which is better?

Servitization enhances value by integrating services with manufacturing, driving higher customer satisfaction and long-term revenue through recurring service contracts. Mass production focuses on high-volume, cost-efficient output, delivering standardized products quickly to meet large market demands. Companies aiming for differentiation and sustained competitive advantage prefer servitization, while those prioritizing scale and low unit costs favor mass production.

Connection

Servitization transforms mass production by integrating after-sales services, enhancing customer value beyond the physical product. This approach leverages scalable manufacturing processes to deliver tailored services, boosting competitiveness and revenue streams. Combining mass production efficiency with service customization optimizes operational performance and customer satisfaction in manufacturing.

Key Terms

Standardization

Mass production emphasizes high-volume manufacturing of standardized products to achieve economies of scale and consistent quality, reducing unit costs significantly. Servitization shifts the focus from selling products to offering customized services, which often requires flexible processes and less emphasis on strict standardization. Explore more to understand how businesses balance standardization with customization in evolving market demands.

Customization

Mass production emphasizes high-volume output with standardized products, minimizing variations to achieve economies of scale. Servitization prioritizes customization by integrating tailored services with products, enhancing customer value and satisfaction. Explore how businesses balance efficiency and personalized solutions to stay competitive.

Value-added services

Mass production emphasizes efficiency and economies of scale, primarily delivering standardized products at lower costs. Servitization shifts the business model toward value-added services such as maintenance, customization, and customer support, enhancing customer satisfaction and creating new revenue streams. Explore how integrating servitization can transform traditional mass production strategies for competitive advantage.

Source and External Links

What Is Mass Production? A Comprehensive Guide - MRPeasy - Mass production is the manufacturing process designed to produce large quantities of standardized products using specialized machinery, division of labor, and efficient flow techniques to ensure high efficiency and consistency.

Mass production - Wikipedia - Mass production involves making many copies of products rapidly using assembly line techniques, where each worker or machine performs a specific step, enabling high-volume output and lower costs through automation and economies of scale.

Mass Production - Overview, How It Works, Advantages - Mass production is the continuous manufacturing of standardized product lines using automation or assembly lines, focusing on repetitive processes, division of labor, and cost reduction to meet large-scale consumer demand.

dowidth.com

dowidth.com