Industrial symbiosis enhances manufacturing efficiency by facilitating the exchange of materials, energy, and by-products between interconnected industries, reducing waste and lowering operational costs. Resource sharing focuses on optimizing asset utilization, such as machinery and facilities, to increase productivity and minimize downtime across manufacturing units. Discover how these strategies can transform your production processes and sustainability efforts.

Why it is important

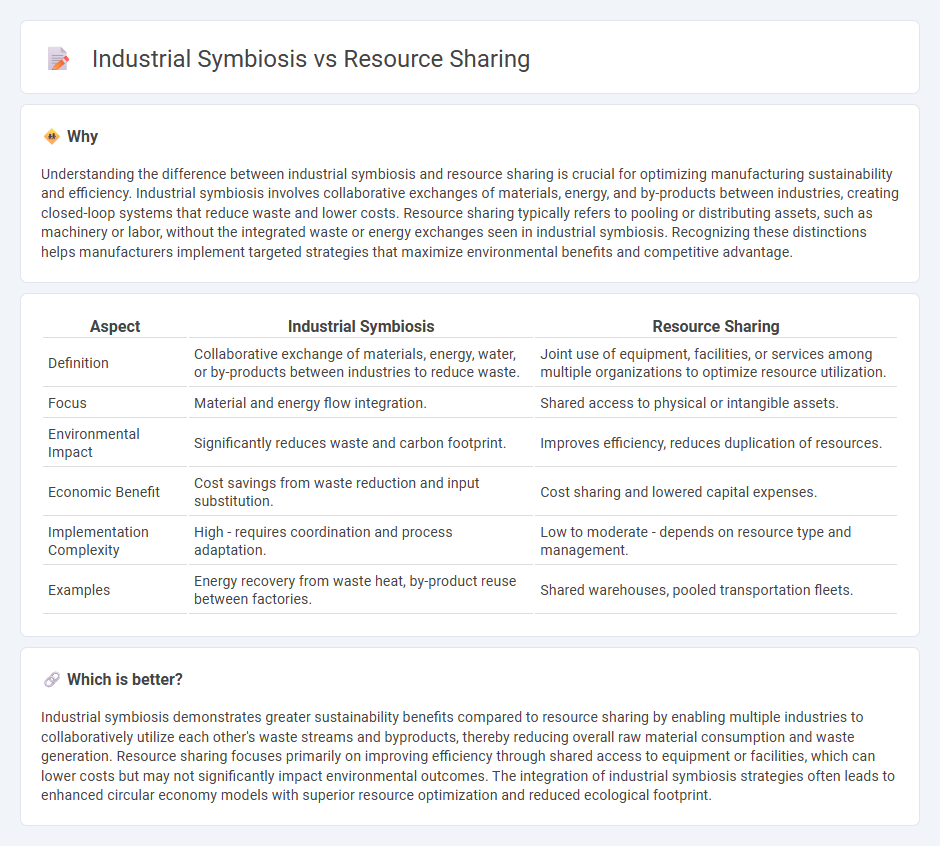

Understanding the difference between industrial symbiosis and resource sharing is crucial for optimizing manufacturing sustainability and efficiency. Industrial symbiosis involves collaborative exchanges of materials, energy, and by-products between industries, creating closed-loop systems that reduce waste and lower costs. Resource sharing typically refers to pooling or distributing assets, such as machinery or labor, without the integrated waste or energy exchanges seen in industrial symbiosis. Recognizing these distinctions helps manufacturers implement targeted strategies that maximize environmental benefits and competitive advantage.

Comparison Table

| Aspect | Industrial Symbiosis | Resource Sharing |

|---|---|---|

| Definition | Collaborative exchange of materials, energy, water, or by-products between industries to reduce waste. | Joint use of equipment, facilities, or services among multiple organizations to optimize resource utilization. |

| Focus | Material and energy flow integration. | Shared access to physical or intangible assets. |

| Environmental Impact | Significantly reduces waste and carbon footprint. | Improves efficiency, reduces duplication of resources. |

| Economic Benefit | Cost savings from waste reduction and input substitution. | Cost sharing and lowered capital expenses. |

| Implementation Complexity | High - requires coordination and process adaptation. | Low to moderate - depends on resource type and management. |

| Examples | Energy recovery from waste heat, by-product reuse between factories. | Shared warehouses, pooled transportation fleets. |

Which is better?

Industrial symbiosis demonstrates greater sustainability benefits compared to resource sharing by enabling multiple industries to collaboratively utilize each other's waste streams and byproducts, thereby reducing overall raw material consumption and waste generation. Resource sharing focuses primarily on improving efficiency through shared access to equipment or facilities, which can lower costs but may not significantly impact environmental outcomes. The integration of industrial symbiosis strategies often leads to enhanced circular economy models with superior resource optimization and reduced ecological footprint.

Connection

Industrial symbiosis fosters manufacturing sustainability by facilitating the exchange of materials, energy, and by-products among factories, reducing raw material consumption and waste. Resource sharing in manufacturing networks enhances operational efficiency by optimizing the use of equipment, labor, and information, leading to cost savings and lower environmental impact. This interconnected approach promotes circular economy principles, driving innovation and resilience within industrial ecosystems.

Key Terms

By-product exchange

By-product exchange is a critical component distinguishing resource sharing and industrial symbiosis, with the latter emphasizing the collaborative reuse of waste materials between industries to enhance sustainability and economic efficiency. Resource sharing typically involves sharing equipment or facilities, while industrial symbiosis actively transforms by-products into valuable inputs, minimizing waste and reducing environmental impact. Explore the dynamics of by-product exchange further to understand its role in advancing circular economy practices.

Shared infrastructure

Resource sharing involves multiple organizations using common assets like equipment, facilities, or services to reduce costs and improve efficiency. Industrial symbiosis takes resource sharing further by creating networks where waste or by-products from one company serve as inputs for another, enhancing sustainability through shared infrastructure such as utilities, transportation, or storage facilities. Explore how these shared infrastructures optimize operational synergy and environmental impact by learning more about industrial symbiosis strategies.

Waste valorization

Resource sharing involves the direct exchange of materials, energy, or by-products between industries to minimize waste, while industrial symbiosis encompasses a broader network of interconnected businesses collaborating for mutual environmental and economic benefits through waste valorization. Waste valorization in industrial symbiosis transforms by-products into valuable resources, enhancing sustainability and reducing landfill dependence. Explore how industrial symbiosis leverages resource sharing for optimized waste valorization and circular economy advancements.

Source and External Links

What Is Resource Sharing in Libraries? - Resource sharing in libraries involves collaboration among libraries to share materials, technology, and expertise to maximize resources, reduce costs, and promote equity by providing broad access to information.

Resource Sharing (ILL) - Resource sharing, also known as Interlibrary Loan, enables users to borrow physical materials or receive electronic documents from other libraries, filling collection gaps and supporting comprehensive access.

Resource Sharing Community: What Is It and Why ... - A resource sharing community is an online platform where multiple users share and collaborate on digital materials, widely used in publishing and education to provide interactive access to content and support learning.

dowidth.com

dowidth.com