Robotic Process Automation (RPA) streamlines manufacturing workflows by automating repetitive digital tasks, enhancing efficiency in administrative and operational processes. Collaborative robots (cobots) work alongside human operators on the factory floor, performing physical, precision-driven tasks that require flexibility and adaptability. Explore the latest advancements in RPA and cobots to transform your manufacturing operations.

Why it is important

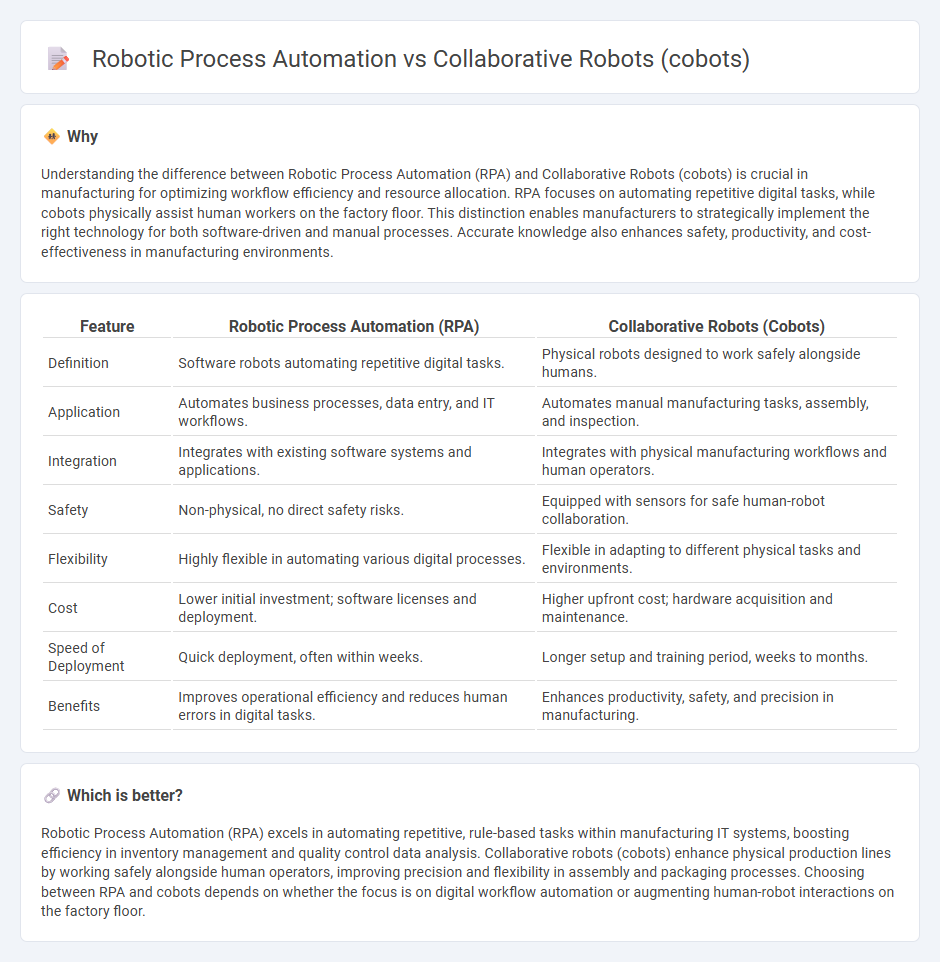

Understanding the difference between Robotic Process Automation (RPA) and Collaborative Robots (cobots) is crucial in manufacturing for optimizing workflow efficiency and resource allocation. RPA focuses on automating repetitive digital tasks, while cobots physically assist human workers on the factory floor. This distinction enables manufacturers to strategically implement the right technology for both software-driven and manual processes. Accurate knowledge also enhances safety, productivity, and cost-effectiveness in manufacturing environments.

Comparison Table

| Feature | Robotic Process Automation (RPA) | Collaborative Robots (Cobots) |

|---|---|---|

| Definition | Software robots automating repetitive digital tasks. | Physical robots designed to work safely alongside humans. |

| Application | Automates business processes, data entry, and IT workflows. | Automates manual manufacturing tasks, assembly, and inspection. |

| Integration | Integrates with existing software systems and applications. | Integrates with physical manufacturing workflows and human operators. |

| Safety | Non-physical, no direct safety risks. | Equipped with sensors for safe human-robot collaboration. |

| Flexibility | Highly flexible in automating various digital processes. | Flexible in adapting to different physical tasks and environments. |

| Cost | Lower initial investment; software licenses and deployment. | Higher upfront cost; hardware acquisition and maintenance. |

| Speed of Deployment | Quick deployment, often within weeks. | Longer setup and training period, weeks to months. |

| Benefits | Improves operational efficiency and reduces human errors in digital tasks. | Enhances productivity, safety, and precision in manufacturing. |

Which is better?

Robotic Process Automation (RPA) excels in automating repetitive, rule-based tasks within manufacturing IT systems, boosting efficiency in inventory management and quality control data analysis. Collaborative robots (cobots) enhance physical production lines by working safely alongside human operators, improving precision and flexibility in assembly and packaging processes. Choosing between RPA and cobots depends on whether the focus is on digital workflow automation or augmenting human-robot interactions on the factory floor.

Connection

Robotic process automation (RPA) integrates with collaborative robots (cobots) by enabling digital workflows to seamlessly control physical tasks in manufacturing environments. Cobots rely on RPA software to interpret data and execute repetitive actions alongside human workers, enhancing precision and efficiency. The synergy between RPA and cobots drives optimized production cycles, reduced errors, and increased operational agility.

Key Terms

Human-robot interaction

Collaborative robots (cobots) enhance human-robot interaction by working alongside employees in shared workspaces, employing advanced sensors and AI to ensure safety and adaptability. In contrast, robotic process automation (RPA) automates repetitive digital tasks without physical interaction, streamlining workflows in sectors like finance and customer service. Discover the critical differences and applications to optimize integration strategies in your business.

Software automation

Collaborative robots (cobots) enhance physical tasks by working alongside humans in shared workspaces, while robotic process automation (RPA) focuses on software automation to optimize repetitive digital workflows. RPA utilizes AI-driven bots to streamline data entry, transaction processing, and rule-based tasks within enterprise software systems, boosting efficiency and reducing human error. Explore deeper insights into how software automation transforms business operations and complements physical robotics.

Flexible deployment

Collaborative robots (cobots) enable flexible deployment through easy integration with human workers in dynamic environments, enhancing adaptability in manufacturing and service sectors. Robotic Process Automation (RPA) offers flexible deployment by automating repetitive digital tasks across various software systems without altering existing infrastructures. Explore more to understand how these technologies transform operational flexibility and efficiency.

Source and External Links

What is a cobot? | The ultimate collaborative robot guide - Collaborative robots (cobots) are robots designed to safely work alongside humans in shared workspaces using sensitive sensors that shut the robot down if interrupted, enabling small and medium manufacturers to automate flexibly and cost-effectively, with the concept dating back to 1996 and commercialized extensively since 2004.

Cobots: A beginner's guide to collaborative robots - Cobots can be categorized by safety features like power and force-limiting, safety-monitored stop, speed and separation monitoring, and hand-guiding modes, allowing varying degrees of interaction and ensuring safe collaboration without barriers.

Why Cobots? - Cobots are cost-effective, safe, and flexible robotic arms designed to make automation accessible for businesses of all sizes by eliminating complex programming and safety fencing, widely adopted with over 100,000 units globally supporting diverse industrial applications.

dowidth.com

dowidth.com