Collaborative robots, designed to work safely alongside human operators, offer flexibility and ease of programming in manufacturing environments. Industrial robots provide high-speed, high-precision automation for repetitive tasks in large-scale production. Explore the differences and benefits of collaborative and industrial robots to optimize your manufacturing processes.

Why it is important

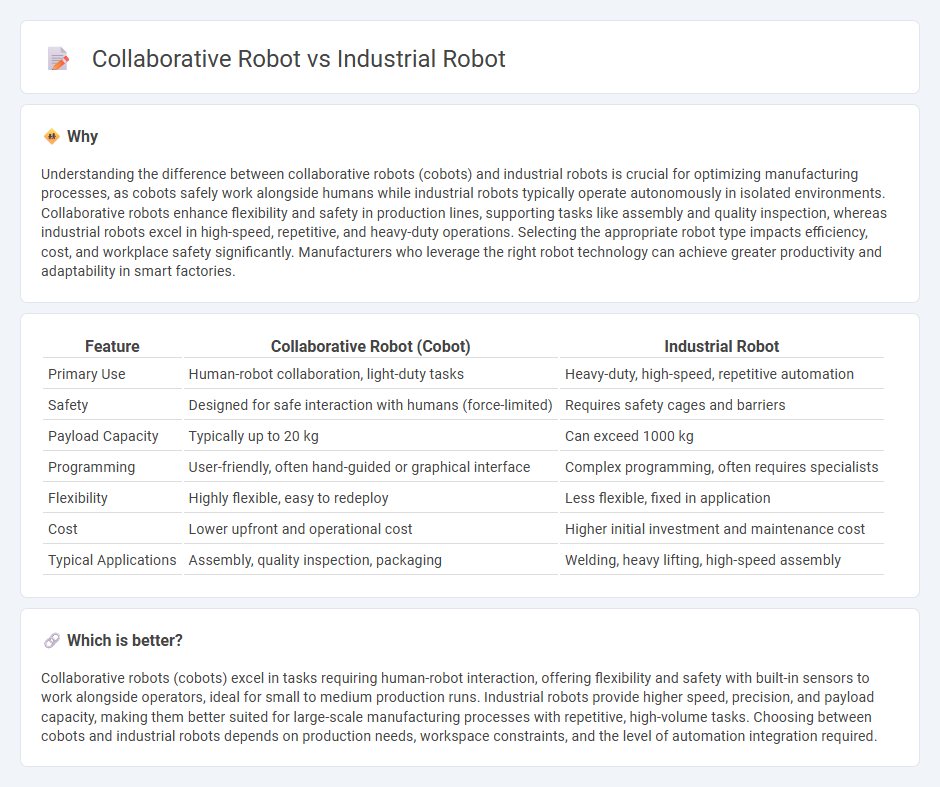

Understanding the difference between collaborative robots (cobots) and industrial robots is crucial for optimizing manufacturing processes, as cobots safely work alongside humans while industrial robots typically operate autonomously in isolated environments. Collaborative robots enhance flexibility and safety in production lines, supporting tasks like assembly and quality inspection, whereas industrial robots excel in high-speed, repetitive, and heavy-duty operations. Selecting the appropriate robot type impacts efficiency, cost, and workplace safety significantly. Manufacturers who leverage the right robot technology can achieve greater productivity and adaptability in smart factories.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Industrial Robot |

|---|---|---|

| Primary Use | Human-robot collaboration, light-duty tasks | Heavy-duty, high-speed, repetitive automation |

| Safety | Designed for safe interaction with humans (force-limited) | Requires safety cages and barriers |

| Payload Capacity | Typically up to 20 kg | Can exceed 1000 kg |

| Programming | User-friendly, often hand-guided or graphical interface | Complex programming, often requires specialists |

| Flexibility | Highly flexible, easy to redeploy | Less flexible, fixed in application |

| Cost | Lower upfront and operational cost | Higher initial investment and maintenance cost |

| Typical Applications | Assembly, quality inspection, packaging | Welding, heavy lifting, high-speed assembly |

Which is better?

Collaborative robots (cobots) excel in tasks requiring human-robot interaction, offering flexibility and safety with built-in sensors to work alongside operators, ideal for small to medium production runs. Industrial robots provide higher speed, precision, and payload capacity, making them better suited for large-scale manufacturing processes with repetitive, high-volume tasks. Choosing between cobots and industrial robots depends on production needs, workspace constraints, and the level of automation integration required.

Connection

Collaborative robots (cobots) and industrial robots are connected through their complementary roles in manufacturing automation, where cobots enhance flexibility by working safely alongside humans while industrial robots handle high-speed, repetitive tasks. Both systems utilize advanced sensors, machine learning, and precise control algorithms to optimize production efficiency and quality. Integration of cobots with traditional industrial robots creates hybrid workcells that maximize productivity, reduce downtime, and improve safety standards across manufacturing environments.

Key Terms

Automation

Industrial robots are designed for high-speed, repetitive tasks in isolated environments to maximize efficiency and precision in automation workflows. Collaborative robots (cobots) enable human-robot interaction, enhancing flexibility by working safely alongside operators without extensive safety barriers. Explore the latest innovations and applications in automation by learning more about these robotic technologies.

Safety

Industrial robots operate in fenced-off areas to prevent human contact during high-speed or heavy-duty tasks, ensuring maximum safety through physical barriers and strict programming constraints. Collaborative robots (cobots) are designed with advanced sensors and force-limiting technology to safely work alongside humans, minimizing injury risk by stopping or slowing down upon detecting human presence. Explore how safety standards like ISO 10218 and ISO/TS 15066 shape the deployment of these robots in various industries.

Human-robot interaction

Industrial robots operate in isolated environments with limited human interaction, designed for high-speed, repetitive tasks, ensuring safety through physical barriers and strict programming. Collaborative robots (cobots) are engineered to work alongside humans, equipped with advanced sensors and safety mechanisms to enable real-time interaction without protective fencing. Explore deeper insights into human-robot interaction to understand the evolving dynamics between industrial automation and collaborative robotics.

Source and External Links

What Are Industrial Robots? - Industrial robots are machines with at least one reprogrammable robotic arm designed to automate manufacturing tasks like assembly and material handling with high speed, precision, and strength, often operating in cages to ensure human safety.

What is an industrial robot? Industrial robot definition - Industrial robots are large, heavy machines fixed in industrial settings to automate intensive production tasks like those on assembly lines, with at least three programmable axes as per ISO standards.

The IFR's use of the term "industrial robot" - Defined by ISO 8373:2021, industrial robots are automatically controlled, reprogrammable multipurpose manipulators with three or more programmable axes used in industrial automation, available in various mechanical structures such as articulated, SCARA, and Cartesian robots.

dowidth.com

dowidth.com