Digital twin technology creates a virtual replica of a physical asset to monitor real-time performance and predict maintenance needs, enhancing manufacturing efficiency. Digital thread integrates data flows across the entire product lifecycle, ensuring seamless communication between design, production, and supply chain processes. Explore how combining digital twin and digital thread can revolutionize modern manufacturing.

Why it is important

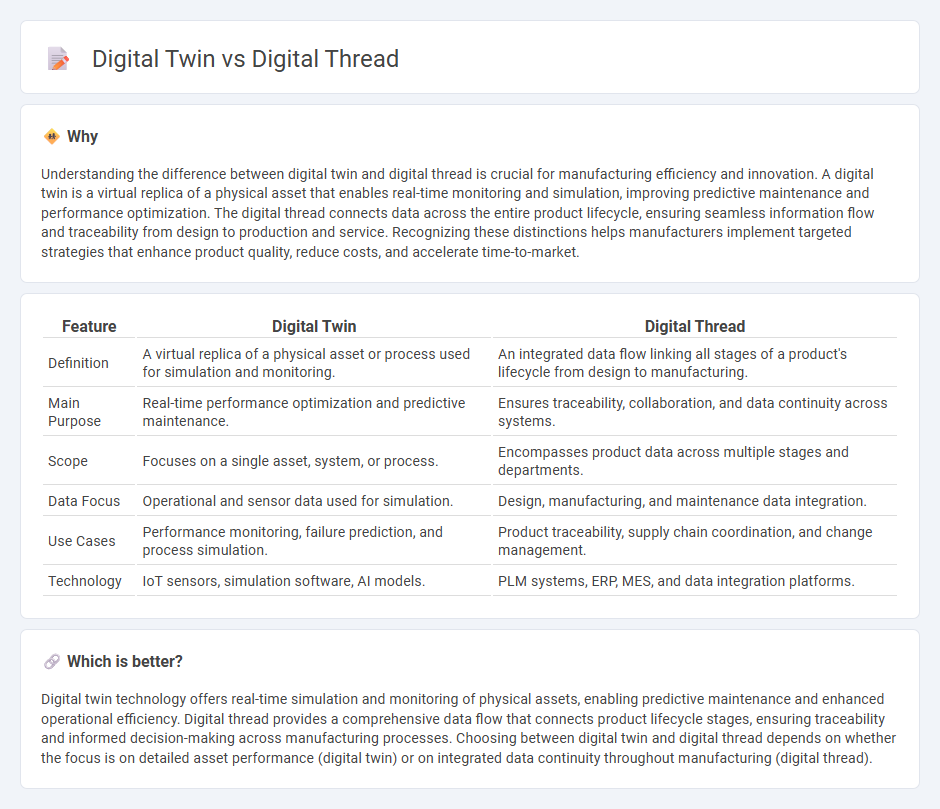

Understanding the difference between digital twin and digital thread is crucial for manufacturing efficiency and innovation. A digital twin is a virtual replica of a physical asset that enables real-time monitoring and simulation, improving predictive maintenance and performance optimization. The digital thread connects data across the entire product lifecycle, ensuring seamless information flow and traceability from design to production and service. Recognizing these distinctions helps manufacturers implement targeted strategies that enhance product quality, reduce costs, and accelerate time-to-market.

Comparison Table

| Feature | Digital Twin | Digital Thread |

|---|---|---|

| Definition | A virtual replica of a physical asset or process used for simulation and monitoring. | An integrated data flow linking all stages of a product's lifecycle from design to manufacturing. |

| Main Purpose | Real-time performance optimization and predictive maintenance. | Ensures traceability, collaboration, and data continuity across systems. |

| Scope | Focuses on a single asset, system, or process. | Encompasses product data across multiple stages and departments. |

| Data Focus | Operational and sensor data used for simulation. | Design, manufacturing, and maintenance data integration. |

| Use Cases | Performance monitoring, failure prediction, and process simulation. | Product traceability, supply chain coordination, and change management. |

| Technology | IoT sensors, simulation software, AI models. | PLM systems, ERP, MES, and data integration platforms. |

Which is better?

Digital twin technology offers real-time simulation and monitoring of physical assets, enabling predictive maintenance and enhanced operational efficiency. Digital thread provides a comprehensive data flow that connects product lifecycle stages, ensuring traceability and informed decision-making across manufacturing processes. Choosing between digital twin and digital thread depends on whether the focus is on detailed asset performance (digital twin) or on integrated data continuity throughout manufacturing (digital thread).

Connection

Digital twin technology creates a virtual replica of physical manufacturing assets, enabling real-time monitoring and simulation of production processes. The digital thread integrates data from design, manufacturing, and performance stages, ensuring seamless information flow and traceability throughout the product lifecycle. Together, digital twin and digital thread enhance predictive maintenance, optimize manufacturing efficiency, and support data-driven decision-making.

Key Terms

Data Integration

Digital thread emphasizes seamless data integration across product lifecycle stages, ensuring continuous data flow from design to manufacturing and maintenance. Digital twin relies on this integrated data to create real-time, virtual replicas of physical assets for simulation and monitoring. Explore how mastering data integration enhances both digital thread and digital twin capabilities.

Real-time Monitoring

Digital thread enables seamless data flow across the entire product lifecycle, integrating real-time monitoring information to improve decision-making and operational efficiency. Digital twin leverages real-time sensor data to create an exact virtual replica for continuous analysis, simulation, and predictive maintenance. Discover how combining digital thread and digital twin enhances real-time monitoring and drives smarter industrial processes.

Lifecycle Management

Digital thread integrates data and processes across the entire product lifecycle, enabling seamless traceability from design to manufacturing, operation, and maintenance. Digital twin creates a real-time virtual replica of a physical asset or system for monitoring, simulation, and predictive maintenance throughout its lifecycle. Explore the benefits of combining digital thread and digital twin for enhanced lifecycle management in advanced industrial applications.

Source and External Links

Digital thread - A data-driven architecture that links information generated across the entire product lifecycle from design through manufacturing, supply chain, and service, enabling seamless data integration and real-time decision-making.

A digital thread: What it is and why you need it - The digital thread is the continuous flow of data and information chained between connected systems, devices, or people, ensuring reliable, accurate, and timely data access across an organization.

Digital thread: redefining digital transformation - A digital thread connects every phase of a product's lifecycle--from concept to production to service--breaking down silos, enabling collaboration, and accelerating decision-making with data-driven insights.

dowidth.com

dowidth.com