Collaborative robots (cobots) enhance manufacturing flexibility by working safely alongside human operators, optimizing tasks such as assembly and quality control. Computer Numerical Control (CNC) machines excel in precision machining, delivering high repeatability and complex part fabrication with minimal human intervention. Explore the key differences and applications of cobots and CNC machines to optimize your manufacturing processes.

Why it is important

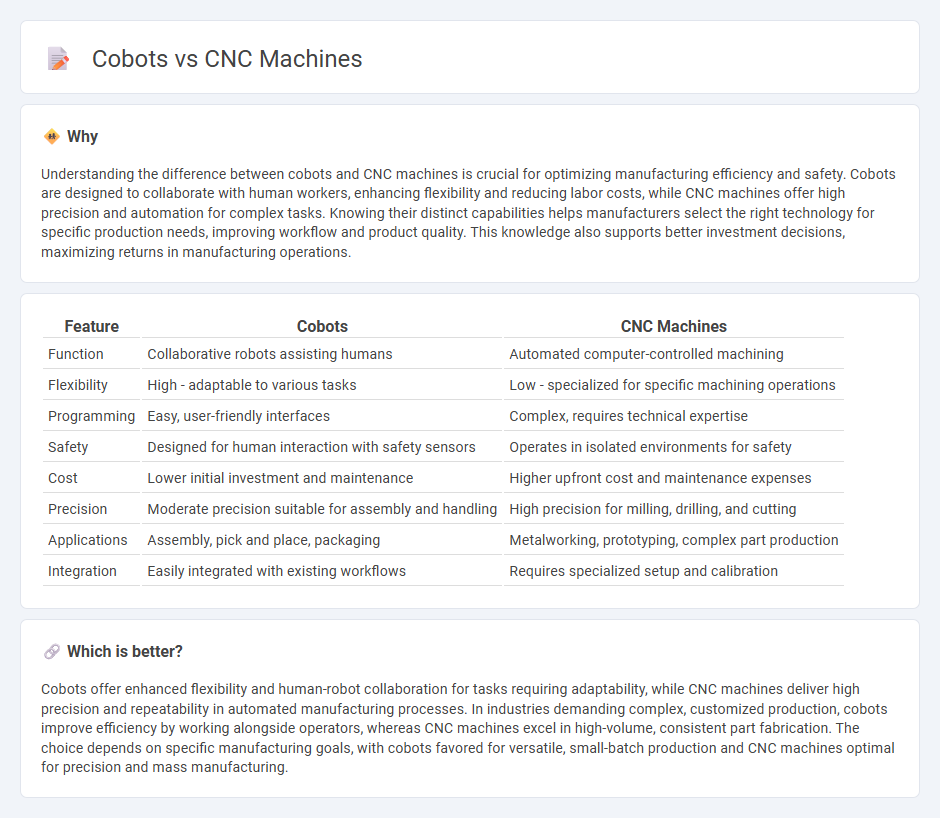

Understanding the difference between cobots and CNC machines is crucial for optimizing manufacturing efficiency and safety. Cobots are designed to collaborate with human workers, enhancing flexibility and reducing labor costs, while CNC machines offer high precision and automation for complex tasks. Knowing their distinct capabilities helps manufacturers select the right technology for specific production needs, improving workflow and product quality. This knowledge also supports better investment decisions, maximizing returns in manufacturing operations.

Comparison Table

| Feature | Cobots | CNC Machines |

|---|---|---|

| Function | Collaborative robots assisting humans | Automated computer-controlled machining |

| Flexibility | High - adaptable to various tasks | Low - specialized for specific machining operations |

| Programming | Easy, user-friendly interfaces | Complex, requires technical expertise |

| Safety | Designed for human interaction with safety sensors | Operates in isolated environments for safety |

| Cost | Lower initial investment and maintenance | Higher upfront cost and maintenance expenses |

| Precision | Moderate precision suitable for assembly and handling | High precision for milling, drilling, and cutting |

| Applications | Assembly, pick and place, packaging | Metalworking, prototyping, complex part production |

| Integration | Easily integrated with existing workflows | Requires specialized setup and calibration |

Which is better?

Cobots offer enhanced flexibility and human-robot collaboration for tasks requiring adaptability, while CNC machines deliver high precision and repeatability in automated manufacturing processes. In industries demanding complex, customized production, cobots improve efficiency by working alongside operators, whereas CNC machines excel in high-volume, consistent part fabrication. The choice depends on specific manufacturing goals, with cobots favored for versatile, small-batch production and CNC machines optimal for precision and mass manufacturing.

Connection

Cobots (collaborative robots) integrate seamlessly with CNC (Computer Numerical Control) machines to enhance automation in manufacturing environments. They perform tasks such as loading and unloading CNC machines, tool changes, and quality inspections, increasing precision and reducing operator fatigue. This synergy improves workflow efficiency, reduces cycle times, and supports flexible production processes in smart factories.

Key Terms

Automation

CNC machines offer precise, repeatable automation for complex machining tasks, making them essential in manufacturing industries requiring high accuracy and speed. Cobots enhance automation by collaborating safely with human workers, providing flexibility and adaptability in dynamic production environments. Explore how integrating CNC machines and cobots can revolutionize your automation processes.

Precision

CNC machines deliver exceptional precision by following pre-programmed instructions to mill, cut, and shape materials with micrometer accuracy. Cobots enhance precision through collaborative sensors and adaptive controls, allowing for real-time adjustments in assembly and intricate tasks. Explore the latest advancements in CNC and cobot precision technologies to optimize manufacturing outcomes.

Flexibility

CNC machines offer high precision and repeatability for complex manufacturing tasks but lack the adaptability required for dynamic production lines. Cobots excel in flexibility by easily integrating with human workers and adapting to varied tasks without extensive reprogramming. Explore how combining CNC technology with cobots can optimize efficiency and responsiveness in modern manufacturing.

Source and External Links

CNC Machines: What Are the Different Types? - This webpage discusses various types of CNC machines, including milling machines, lathes, routers, plasma cutters, electric discharge machines, and laser cutters.

Computer Numerical Control - This Wikipedia page explains the basics of CNC machines, their operation, and various applications in manufacturing processes.

What is CNC Machining? - This article provides an overview of CNC machining, its role in manufacturing, and the variety of machinery it operates.

dowidth.com

dowidth.com