Edge computing enhances manufacturing by processing data locally on devices, reducing latency and improving real-time decision-making compared to traditional legacy SCADA systems that rely on centralized data processing. Legacy SCADA systems often struggle with scalability and slower response times, limiting their effectiveness in modern, complex manufacturing environments. Discover how integrating edge computing can revolutionize industrial operations for greater efficiency and agility.

Why it is important

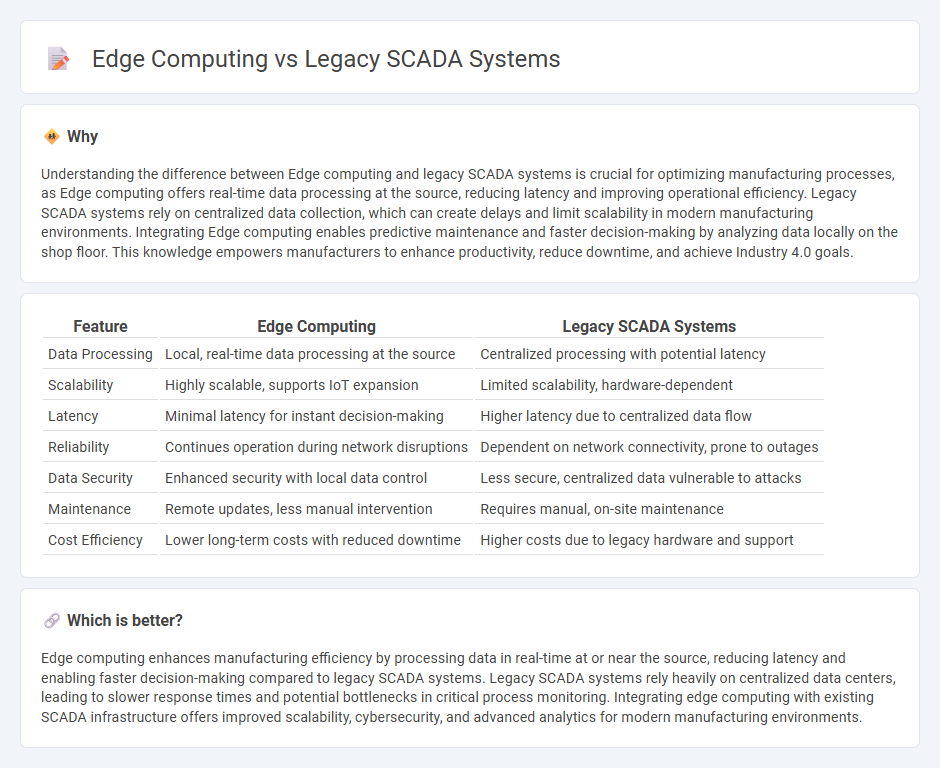

Understanding the difference between Edge computing and legacy SCADA systems is crucial for optimizing manufacturing processes, as Edge computing offers real-time data processing at the source, reducing latency and improving operational efficiency. Legacy SCADA systems rely on centralized data collection, which can create delays and limit scalability in modern manufacturing environments. Integrating Edge computing enables predictive maintenance and faster decision-making by analyzing data locally on the shop floor. This knowledge empowers manufacturers to enhance productivity, reduce downtime, and achieve Industry 4.0 goals.

Comparison Table

| Feature | Edge Computing | Legacy SCADA Systems |

|---|---|---|

| Data Processing | Local, real-time data processing at the source | Centralized processing with potential latency |

| Scalability | Highly scalable, supports IoT expansion | Limited scalability, hardware-dependent |

| Latency | Minimal latency for instant decision-making | Higher latency due to centralized data flow |

| Reliability | Continues operation during network disruptions | Dependent on network connectivity, prone to outages |

| Data Security | Enhanced security with local data control | Less secure, centralized data vulnerable to attacks |

| Maintenance | Remote updates, less manual intervention | Requires manual, on-site maintenance |

| Cost Efficiency | Lower long-term costs with reduced downtime | Higher costs due to legacy hardware and support |

Which is better?

Edge computing enhances manufacturing efficiency by processing data in real-time at or near the source, reducing latency and enabling faster decision-making compared to legacy SCADA systems. Legacy SCADA systems rely heavily on centralized data centers, leading to slower response times and potential bottlenecks in critical process monitoring. Integrating edge computing with existing SCADA infrastructure offers improved scalability, cybersecurity, and advanced analytics for modern manufacturing environments.

Connection

Edge computing enhances Legacy SCADA systems by enabling real-time data processing closer to the source, reducing latency and improving operational efficiency in manufacturing environments. Integrating edge devices with SCADA infrastructure allows for more responsive monitoring and control of industrial processes, supporting predictive maintenance and minimizing downtime. This connection bridges traditional automation systems with modern IoT technologies, fostering smarter, data-driven manufacturing operations.

Key Terms

Centralized Control

Legacy SCADA systems rely heavily on centralized control architectures, which often lead to latency issues and limited real-time responsiveness due to data processing confined to a central hub. Edge computing decentralizes processing by bringing computation and data storage closer to production and operational sources, enhancing real-time decision-making and reducing network bandwidth usage. Explore the benefits and limitations of both approaches to optimize industrial automation and operational efficiency.

Real-time Data Processing

Legacy SCADA systems often suffer from latency issues and centralized data processing that limit real-time responsiveness in industrial automation. Edge computing enables decentralized data processing near the source, significantly reducing response times and enhancing real-time analytics capabilities. Explore how edge computing transforms real-time data processing compared to traditional SCADA systems.

Decentralization

Legacy SCADA systems rely heavily on centralized data processing hubs, which can create bottlenecks and single points of failure in critical industrial operations. Edge computing decentralizes data processing by distributing analytics and control closer to the data sources, enhancing responsiveness and system resilience in real-time environments. Explore how decentralization via edge computing transforms operational efficiency and security in industrial control systems.

Source and External Links

Legacy System Modernization with SCADA Integration - Legacy SCADA systems, often customized and outdated, are becoming obsolete; modernization with SCADA integration helps manufacturers increase efficiency, agility, and productivity by upgrading interfaces and running legacy and new systems in parallel to ensure full functionality.

The cost of legacy SCADA systems - Legacy SCADA systems include aged hardware prone to unexpected failures and have insufficient security measures, making them a major operational risk and costly liability for asset owners.

Why Legacy SCADA Systems Are Easy Targets for Modern ... - Legacy SCADA systems are increasingly vulnerable to cyberattacks due to outdated security capabilities, which can be mitigated by modern network strengthening solutions.

dowidth.com

dowidth.com