Condition-based monitoring leverages real-time data from sensors to predict equipment failures and schedule maintenance proactively, minimizing downtime and extending asset lifespan. Run-to-failure maintenance involves operating machinery until breakdown occurs, leading to unpredictable interruptions and higher repair costs. Explore more to understand which strategy optimizes your manufacturing operations.

Why it is important

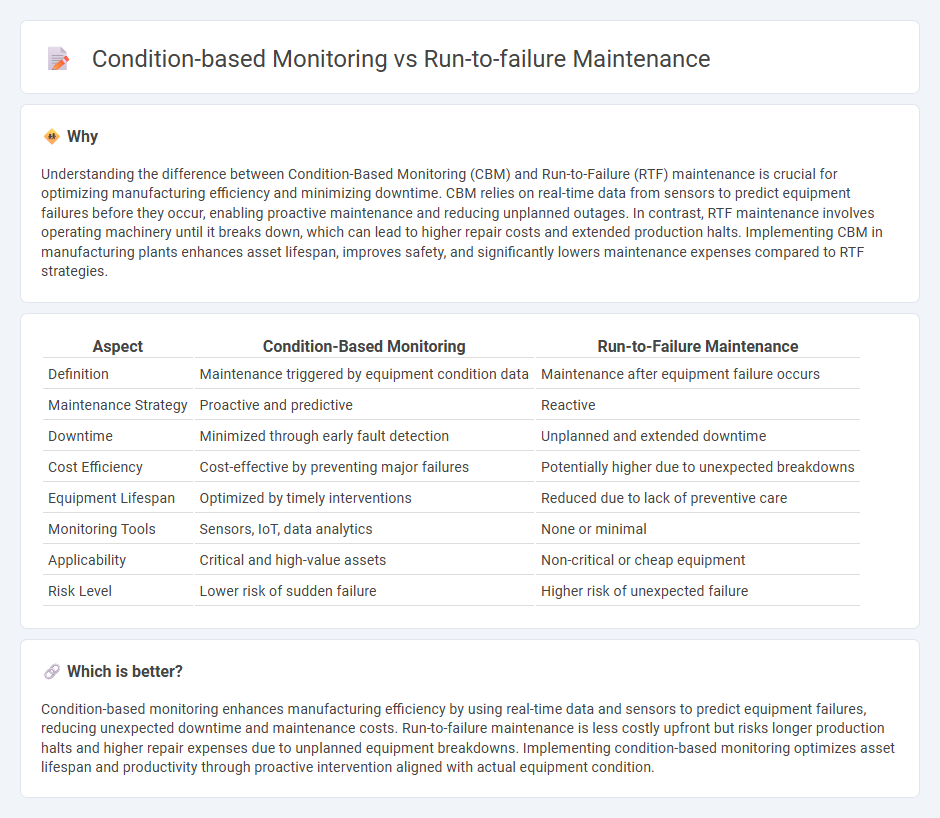

Understanding the difference between Condition-Based Monitoring (CBM) and Run-to-Failure (RTF) maintenance is crucial for optimizing manufacturing efficiency and minimizing downtime. CBM relies on real-time data from sensors to predict equipment failures before they occur, enabling proactive maintenance and reducing unplanned outages. In contrast, RTF maintenance involves operating machinery until it breaks down, which can lead to higher repair costs and extended production halts. Implementing CBM in manufacturing plants enhances asset lifespan, improves safety, and significantly lowers maintenance expenses compared to RTF strategies.

Comparison Table

| Aspect | Condition-Based Monitoring | Run-to-Failure Maintenance |

|---|---|---|

| Definition | Maintenance triggered by equipment condition data | Maintenance after equipment failure occurs |

| Maintenance Strategy | Proactive and predictive | Reactive |

| Downtime | Minimized through early fault detection | Unplanned and extended downtime |

| Cost Efficiency | Cost-effective by preventing major failures | Potentially higher due to unexpected breakdowns |

| Equipment Lifespan | Optimized by timely interventions | Reduced due to lack of preventive care |

| Monitoring Tools | Sensors, IoT, data analytics | None or minimal |

| Applicability | Critical and high-value assets | Non-critical or cheap equipment |

| Risk Level | Lower risk of sudden failure | Higher risk of unexpected failure |

Which is better?

Condition-based monitoring enhances manufacturing efficiency by using real-time data and sensors to predict equipment failures, reducing unexpected downtime and maintenance costs. Run-to-failure maintenance is less costly upfront but risks longer production halts and higher repair expenses due to unplanned equipment breakdowns. Implementing condition-based monitoring optimizes asset lifespan and productivity through proactive intervention aligned with actual equipment condition.

Connection

Condition-based monitoring leverages real-time data from sensors to detect equipment anomalies before failure occurs, enabling targeted interventions. Run-to-failure maintenance accepts equipment operation until fault or breakdown, often relying on condition-based data to optimize the timing of these failures. Integrating condition-based monitoring enhances run-to-failure strategies by reducing unexpected downtime and extending asset life through informed decision-making.

Key Terms

Downtime

Run-to-failure maintenance often results in unpredictable and extended downtime due to unexpected equipment breakdowns, increasing operational costs and production losses. Condition-based monitoring leverages real-time data and sensor technology to predict and prevent failures, significantly reducing unplanned downtime and optimizing maintenance schedules. Explore how adopting condition-based monitoring can transform your maintenance strategy and minimize downtime.

Sensors

Sensors play a critical role in condition-based monitoring by continuously collecting real-time data on equipment performance, enabling early detection of potential faults and preventing unexpected breakdowns. In contrast, run-to-failure maintenance relies on the absence of sensor input, resulting in repairs only after equipment failure occurs, often causing higher downtime and repair costs. Explore how advanced sensor technologies enhance predictive maintenance strategies and optimize asset management.

Failure prediction

Run-to-failure maintenance relies on repairing equipment only after a breakdown occurs, leading to unexpected downtime and potential high repair costs. Condition-based monitoring uses real-time data from sensors to predict failures before they happen, enabling timely interventions and reducing unplanned outages. Discover how advanced failure prediction models enhance maintenance strategies for improved operational efficiency.

Source and External Links

What Is Run-to-Failure Maintenance? | Learning Center - Run-to-failure (RTF) maintenance is a deliberate strategy where assets are used until they break down, only then receiving repair or replacement, and is best suited for non-critical, cheap, or easily replaceable equipment.

Run-To-Failure vs Breakdown Maintenance - RTF lets equipment operate until failure, requiring no regular maintenance, and is cost-effective for non-critical assets with low repair costs and minimal downtime impact.

When to implement run-to-failure (RTF) maintenance - In RTF, no active maintenance or inspections are performed before failure; after failure, the broken part is simply replaced rather than repaired.

dowidth.com

dowidth.com