Cobotics enhances manufacturing efficiency by enabling collaborative robots to work safely alongside human operators, improving precision and flexibility on the production line. Machine vision systems utilize advanced cameras and AI algorithms to inspect products, detect defects, and guide robotic operations with high accuracy. Explore how integrating cobotics and machine vision transforms industrial automation and boosts productivity.

Why it is important

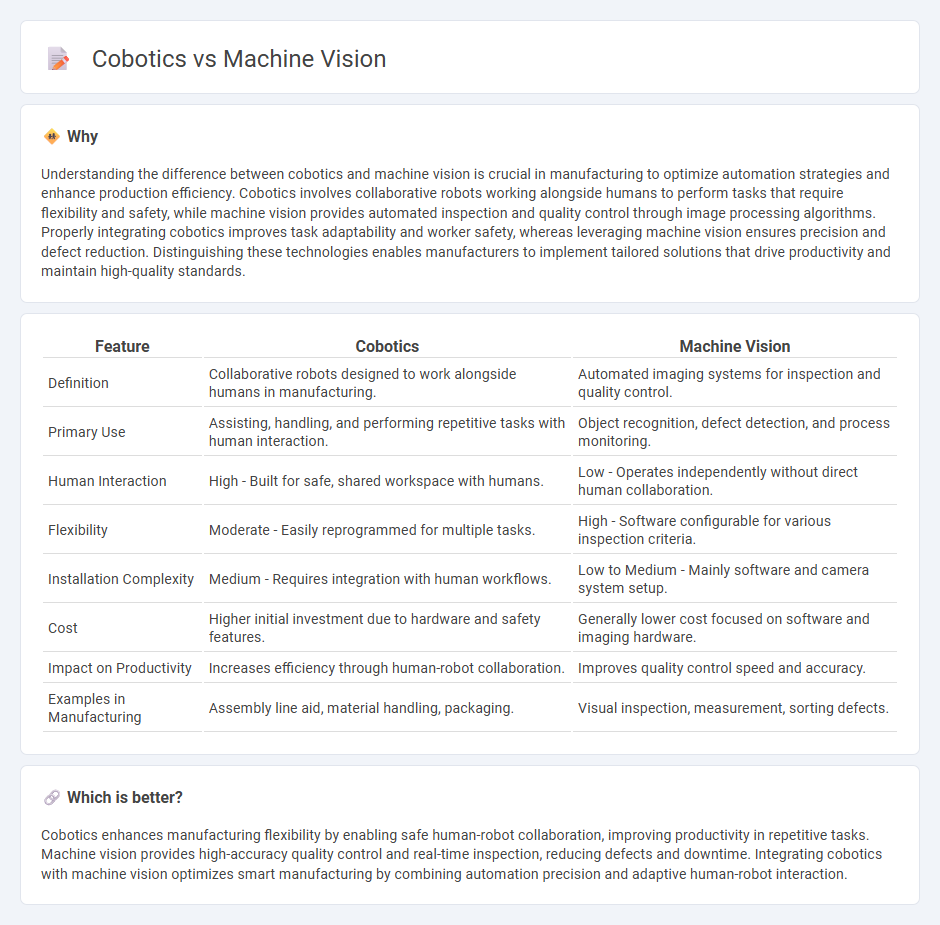

Understanding the difference between cobotics and machine vision is crucial in manufacturing to optimize automation strategies and enhance production efficiency. Cobotics involves collaborative robots working alongside humans to perform tasks that require flexibility and safety, while machine vision provides automated inspection and quality control through image processing algorithms. Properly integrating cobotics improves task adaptability and worker safety, whereas leveraging machine vision ensures precision and defect reduction. Distinguishing these technologies enables manufacturers to implement tailored solutions that drive productivity and maintain high-quality standards.

Comparison Table

| Feature | Cobotics | Machine Vision |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans in manufacturing. | Automated imaging systems for inspection and quality control. |

| Primary Use | Assisting, handling, and performing repetitive tasks with human interaction. | Object recognition, defect detection, and process monitoring. |

| Human Interaction | High - Built for safe, shared workspace with humans. | Low - Operates independently without direct human collaboration. |

| Flexibility | Moderate - Easily reprogrammed for multiple tasks. | High - Software configurable for various inspection criteria. |

| Installation Complexity | Medium - Requires integration with human workflows. | Low to Medium - Mainly software and camera system setup. |

| Cost | Higher initial investment due to hardware and safety features. | Generally lower cost focused on software and imaging hardware. |

| Impact on Productivity | Increases efficiency through human-robot collaboration. | Improves quality control speed and accuracy. |

| Examples in Manufacturing | Assembly line aid, material handling, packaging. | Visual inspection, measurement, sorting defects. |

Which is better?

Cobotics enhances manufacturing flexibility by enabling safe human-robot collaboration, improving productivity in repetitive tasks. Machine vision provides high-accuracy quality control and real-time inspection, reducing defects and downtime. Integrating cobotics with machine vision optimizes smart manufacturing by combining automation precision and adaptive human-robot interaction.

Connection

Cobotics and machine vision work synergistically in manufacturing to enhance automation by enabling collaborative robots to perceive and interact with their environment accurately. Machine vision systems provide real-time data and visual feedback that allows cobots to perform complex tasks such as quality inspection, object recognition, and precise manipulation. This integration improves production efficiency, reduces errors, and ensures higher consistency in manufacturing processes.

Key Terms

**Machine Vision:**

Machine vision integrates advanced imaging technologies and AI algorithms to enable automated inspection, quality control, and object recognition in manufacturing, boosting precision and reducing human error. Unlike cobotics, which emphasizes human-robot interaction and collaboration, machine vision operates independently or alongside robotic systems to enhance operational accuracy and speed. Explore how machine vision transforms industrial automation and quality assurance processes.

Image Processing

Machine vision leverages advanced image processing algorithms to analyze visual data for quality inspection, object recognition, and automation in manufacturing. Cobotics integrates collaborative robots with image processing to enhance safety and precision in human-robot interactions, enabling adaptable and real-time decision-making. Explore how image processing drives innovation in both machine vision and cobotic applications for smarter industrial automation.

Pattern Recognition

Machine vision systems excel in pattern recognition by leveraging advanced cameras and AI algorithms to identify shapes, textures, and anomalies with high accuracy. Cobotics integrates these machine vision capabilities with collaborative robots, enabling real-time pattern recognition to improve precision and safety in shared human-robot tasks. Explore how pattern recognition innovations in both fields drive efficiency and innovation in automated environments.

Source and External Links

What Is Machine Vision? - Intel - Machine vision uses smart cameras, industrial PCs, and deep learning to enable robots and automation systems to perform tasks like quality inspection and robotic guidance in manufacturing, distinguishing it from the broader field of computer vision focused on understanding visual data in varied applications.

Machine Vision Vs Computer Vision - What Is The Difference? | Zebra - Machine vision is a practical subset of computer vision applied mainly in industry to inspect objects, detect flaws, classify and verify parts, often using AI for faster decisions, while computer vision covers wider image analysis tasks including facial recognition and augmented reality.

What is Machine Vision? | Definition from TechTarget - Machine vision combines cameras and image processing to enable robots to perform tasks such as sorting and inventory management, often integrated with AI and edge computing for real-time decisions and enhanced safety in collaboration with humans.

dowidth.com

dowidth.com