Cobotics integrates collaborative robots designed to work alongside human operators, enhancing flexibility and safety in manufacturing environments. Traditional robotics typically involves automated machines operating independently in isolated settings to maximize speed and precision. Explore how cobotics and robotics each revolutionize industrial processes and drive productivity.

Why it is important

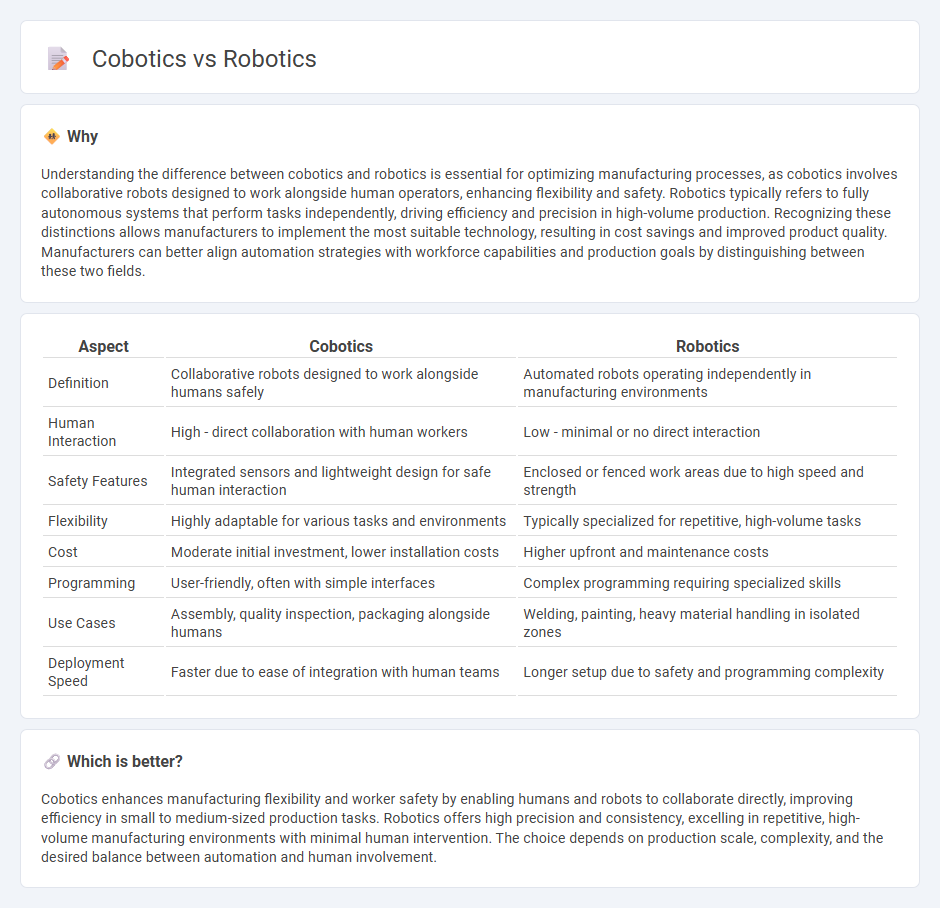

Understanding the difference between cobotics and robotics is essential for optimizing manufacturing processes, as cobotics involves collaborative robots designed to work alongside human operators, enhancing flexibility and safety. Robotics typically refers to fully autonomous systems that perform tasks independently, driving efficiency and precision in high-volume production. Recognizing these distinctions allows manufacturers to implement the most suitable technology, resulting in cost savings and improved product quality. Manufacturers can better align automation strategies with workforce capabilities and production goals by distinguishing between these two fields.

Comparison Table

| Aspect | Cobotics | Robotics |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans safely | Automated robots operating independently in manufacturing environments |

| Human Interaction | High - direct collaboration with human workers | Low - minimal or no direct interaction |

| Safety Features | Integrated sensors and lightweight design for safe human interaction | Enclosed or fenced work areas due to high speed and strength |

| Flexibility | Highly adaptable for various tasks and environments | Typically specialized for repetitive, high-volume tasks |

| Cost | Moderate initial investment, lower installation costs | Higher upfront and maintenance costs |

| Programming | User-friendly, often with simple interfaces | Complex programming requiring specialized skills |

| Use Cases | Assembly, quality inspection, packaging alongside humans | Welding, painting, heavy material handling in isolated zones |

| Deployment Speed | Faster due to ease of integration with human teams | Longer setup due to safety and programming complexity |

Which is better?

Cobotics enhances manufacturing flexibility and worker safety by enabling humans and robots to collaborate directly, improving efficiency in small to medium-sized production tasks. Robotics offers high precision and consistency, excelling in repetitive, high-volume manufacturing environments with minimal human intervention. The choice depends on production scale, complexity, and the desired balance between automation and human involvement.

Connection

Cobotics and robotics intersect by combining human collaboration with automated precision, enhancing manufacturing efficiency and safety. Collaborative robots, or cobots, operate alongside human workers, complementing traditional industrial robots that perform repetitive and high-speed tasks independently. Integration of cobotics with robotics optimizes production workflows, reduces downtime, and improves adaptability in complex manufacturing environments.

Key Terms

Automation

Robotics involves the use of fully autonomous machines performing tasks without human intervention, primarily aimed at increasing efficiency and precision in automation processes. Cobotics emphasizes collaborative robots designed to work safely alongside humans, enhancing productivity by combining human flexibility with robotic strength. Explore the differences between robotics and cobotics to optimize your automation strategy effectively.

Human-robot collaboration

Human-robot collaboration in cobotics emphasizes shared tasks where robots assist humans safely and efficiently within the same workspace, unlike traditional robotics which often operate autonomously in isolated environments. Cobots are designed with advanced sensors and AI to adapt to human movements, enhancing productivity and reducing workplace injuries. Explore the benefits and applications of human-robot collaboration in cobotics to optimize your workflow.

Safety systems

Robotics safety systems rely on physical barriers, emergency stop buttons, and advanced sensors to prevent accidents during automated operations. Cobotics safety emphasizes human-robot collaboration with features like force limitation, speed monitoring, and real-time presence detection to ensure safe, shared workspaces. Explore the latest innovations in robotics and cobotics safety systems to enhance your industrial automation strategy.

Source and External Links

Robotics: What Are Robots? - Built In - Robotics is an interdisciplinary field combining science, engineering, and technology to create robots that replicate or replace human actions, ranging from simple repetitive tasks to complex autonomous operations powered by artificial intelligence.

Robotics - Wikipedia - Robotics involves the design, construction, operation, and use of robots, integrating mechanical engineering, computer science, and other fields to build machines that assist humans, often in hazardous or repetitive environments, with growing emphasis on autonomous navigation and environment interaction.

Robotics | Definition, Applications, & Facts | Britannica - Robotics is the design and use of machines to perform tasks traditionally done by humans, combining sensors, artificial intelligence, and mobility to enable robots to operate in varied environments, including industrial, hazardous, or unstructured settings.

dowidth.com

dowidth.com