Adaptive machining leverages real-time data to dynamically adjust manufacturing processes, enhancing precision and efficiency during production. Predictive maintenance utilizes sensor data and analytics to foresee equipment failures, minimizing downtime and optimizing maintenance schedules. Explore how combining these strategies can revolutionize manufacturing operations.

Why it is important

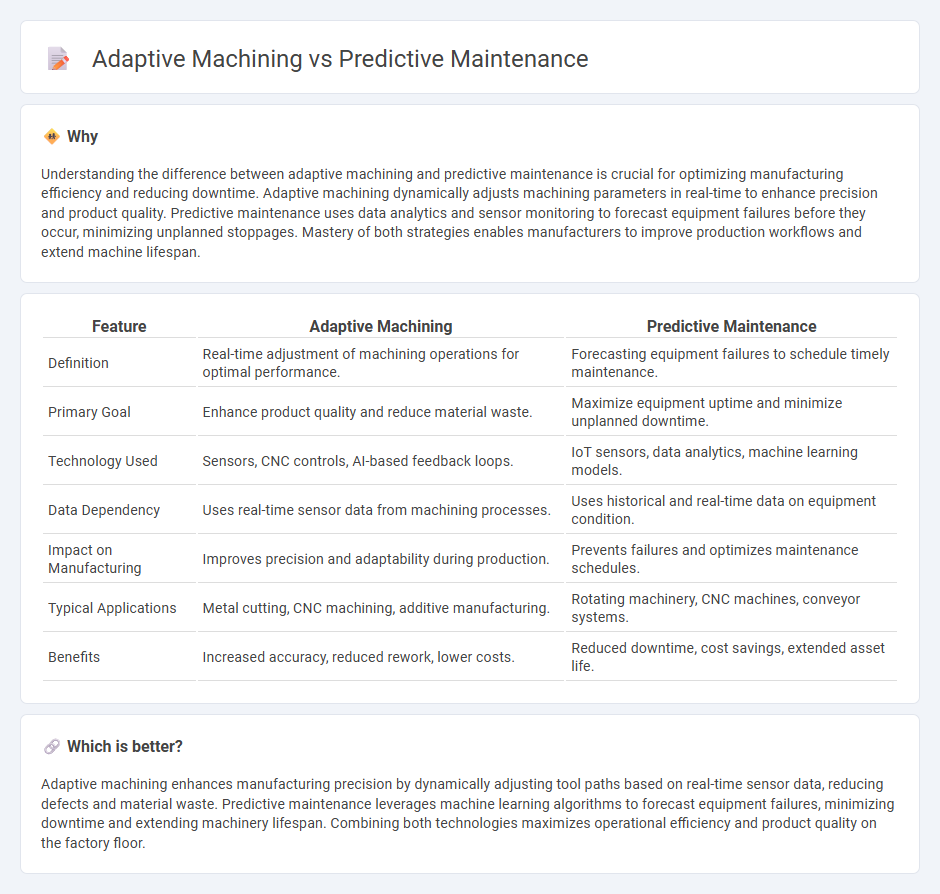

Understanding the difference between adaptive machining and predictive maintenance is crucial for optimizing manufacturing efficiency and reducing downtime. Adaptive machining dynamically adjusts machining parameters in real-time to enhance precision and product quality. Predictive maintenance uses data analytics and sensor monitoring to forecast equipment failures before they occur, minimizing unplanned stoppages. Mastery of both strategies enables manufacturers to improve production workflows and extend machine lifespan.

Comparison Table

| Feature | Adaptive Machining | Predictive Maintenance |

|---|---|---|

| Definition | Real-time adjustment of machining operations for optimal performance. | Forecasting equipment failures to schedule timely maintenance. |

| Primary Goal | Enhance product quality and reduce material waste. | Maximize equipment uptime and minimize unplanned downtime. |

| Technology Used | Sensors, CNC controls, AI-based feedback loops. | IoT sensors, data analytics, machine learning models. |

| Data Dependency | Uses real-time sensor data from machining processes. | Uses historical and real-time data on equipment condition. |

| Impact on Manufacturing | Improves precision and adaptability during production. | Prevents failures and optimizes maintenance schedules. |

| Typical Applications | Metal cutting, CNC machining, additive manufacturing. | Rotating machinery, CNC machines, conveyor systems. |

| Benefits | Increased accuracy, reduced rework, lower costs. | Reduced downtime, cost savings, extended asset life. |

Which is better?

Adaptive machining enhances manufacturing precision by dynamically adjusting tool paths based on real-time sensor data, reducing defects and material waste. Predictive maintenance leverages machine learning algorithms to forecast equipment failures, minimizing downtime and extending machinery lifespan. Combining both technologies maximizes operational efficiency and product quality on the factory floor.

Connection

Adaptive machining enhances manufacturing efficiency by continuously adjusting cutting parameters based on real-time sensor data, minimizing tool wear and defects. Predictive maintenance utilizes machine learning algorithms to analyze equipment performance data, forecasting potential failures before they occur. Integrating adaptive machining with predictive maintenance creates a seamless feedback loop that optimizes machine uptime, performance, and product quality in smart manufacturing systems.

Key Terms

Condition Monitoring

Predictive maintenance utilizes condition monitoring data such as vibration analysis, temperature trends, and acoustic signals to forecast equipment failures before they occur, reducing downtime and maintenance costs. Adaptive machining integrates real-time condition monitoring metrics directly into CNC machine controls, allowing dynamic adjustments to cutting parameters for improved tool life and product quality. Explore how condition monitoring transforms manufacturing efficiency through predictive maintenance and adaptive machining technologies.

Real-time Feedback

Predictive maintenance leverages real-time sensor data and advanced analytics to forecast equipment failures, reducing unplanned downtime and optimizing maintenance schedules. Adaptive machining utilizes live feedback from cutting tools and workpieces to dynamically adjust machining parameters, enhancing precision and tool life. Explore how integrating these real-time feedback systems can revolutionize manufacturing efficiency and reliability.

AI-powered Control

Predictive maintenance leverages AI algorithms to analyze real-time sensor data and predict equipment failures before they occur, minimizing downtime and optimizing operational efficiency. Adaptive machining uses AI-driven control systems to dynamically adjust machining parameters in response to changing conditions, enhancing precision and reducing waste. Explore how AI-powered control revolutionizes manufacturing processes through these advanced techniques.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses sensor data and machine learning to continuously assess equipment health in real time, predict future failures, and optimize maintenance scheduling to avoid unnecessary costs and downtime by performing maintenance only when needed.

Predictive maintenance - Wikipedia - Predictive maintenance estimates when maintenance should be performed based on the actual condition of equipment using measurements and forecasting techniques, enabling better planning, fewer unplanned stops, increased equipment lifetime, and improved safety.

What is Predictive Maintenance? Benefits, Challenges & Examples - Geotab - Predictive maintenance analyzes real-time data from sensors and other sources to detect deviations and predict failures, helping to optimize vehicle uptime, reduce maintenance costs, prioritize urgent repairs, and enhance fleet safety.

dowidth.com

dowidth.com