Robotic Process Automation (RPA) streamlines repetitive manufacturing tasks by automating data entry and quality control measures, enhancing operational efficiency. Enterprise Resource Planning (ERP) integrates core processes such as supply chain management, inventory tracking, and production scheduling into a unified system for holistic resource management. Explore how RPA and ERP technologies can transform manufacturing productivity and decision-making.

Why it is important

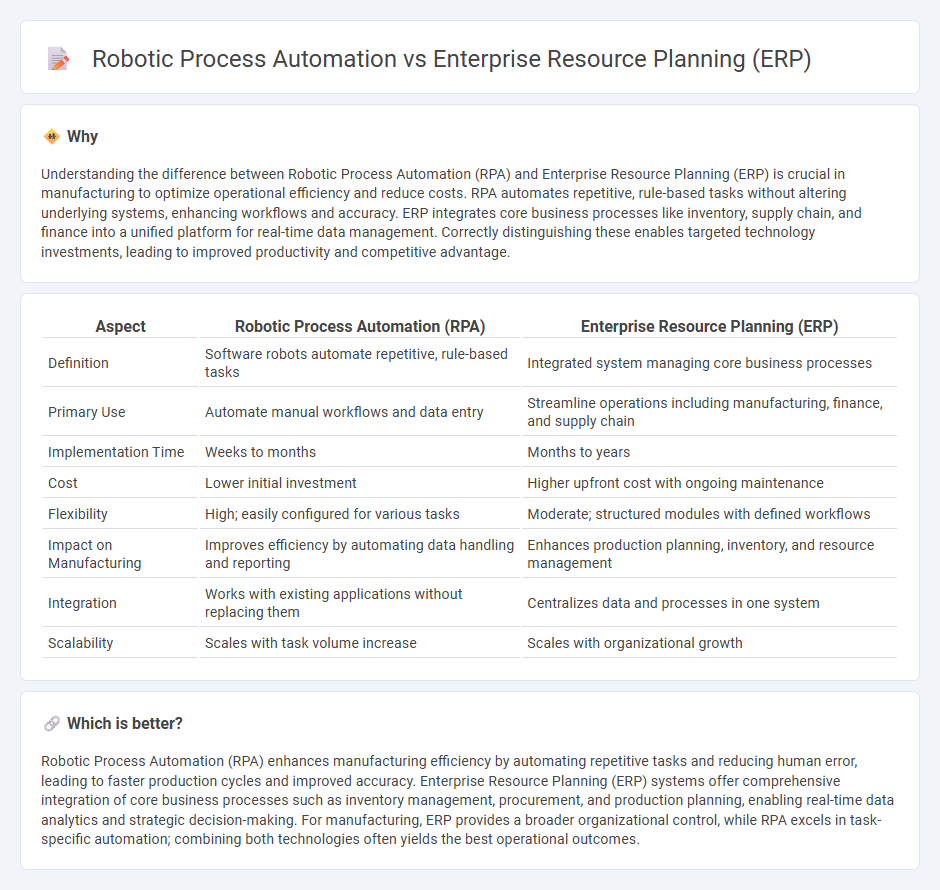

Understanding the difference between Robotic Process Automation (RPA) and Enterprise Resource Planning (ERP) is crucial in manufacturing to optimize operational efficiency and reduce costs. RPA automates repetitive, rule-based tasks without altering underlying systems, enhancing workflows and accuracy. ERP integrates core business processes like inventory, supply chain, and finance into a unified platform for real-time data management. Correctly distinguishing these enables targeted technology investments, leading to improved productivity and competitive advantage.

Comparison Table

| Aspect | Robotic Process Automation (RPA) | Enterprise Resource Planning (ERP) |

|---|---|---|

| Definition | Software robots automate repetitive, rule-based tasks | Integrated system managing core business processes |

| Primary Use | Automate manual workflows and data entry | Streamline operations including manufacturing, finance, and supply chain |

| Implementation Time | Weeks to months | Months to years |

| Cost | Lower initial investment | Higher upfront cost with ongoing maintenance |

| Flexibility | High; easily configured for various tasks | Moderate; structured modules with defined workflows |

| Impact on Manufacturing | Improves efficiency by automating data handling and reporting | Enhances production planning, inventory, and resource management |

| Integration | Works with existing applications without replacing them | Centralizes data and processes in one system |

| Scalability | Scales with task volume increase | Scales with organizational growth |

Which is better?

Robotic Process Automation (RPA) enhances manufacturing efficiency by automating repetitive tasks and reducing human error, leading to faster production cycles and improved accuracy. Enterprise Resource Planning (ERP) systems offer comprehensive integration of core business processes such as inventory management, procurement, and production planning, enabling real-time data analytics and strategic decision-making. For manufacturing, ERP provides a broader organizational control, while RPA excels in task-specific automation; combining both technologies often yields the best operational outcomes.

Connection

Robotic Process Automation (RPA) enhances Enterprise Resource Planning (ERP) systems by automating repetitive, time-consuming tasks such as data entry, order processing, and inventory management, leading to increased operational efficiency and reduced human error in manufacturing. Integration of RPA with ERP enables real-time data synchronization, improving decision-making accuracy and streamlining workflows across supply chain and production planning. This connection supports scalable manufacturing processes, boosts productivity, and facilitates faster response times to market demands.

Key Terms

Integration

Enterprise Resource Planning (ERP) systems centralize business processes into a unified platform, ensuring seamless data flow across departments such as finance, supply chain, and human resources. Robotic Process Automation (RPA) enhances integration by automating repetitive tasks and bridging gaps between disparate software, increasing operational efficiency without replacing core ERP functions. Explore how combining ERP with RPA optimizes integration to drive digital transformation in your organization.

Automation

Enterprise Resource Planning (ERP) systems streamline business processes by integrating core functions such as finance, supply chain, and human resources into a unified platform, enhancing operational efficiency with centralized data management. Robotic Process Automation (RPA) focuses on automating repetitive, rule-based tasks across various applications, increasing accuracy and speed without altering existing systems. Explore how combining ERP and RPA can maximize automation benefits and drive digital transformation in your organization.

Workflow

Enterprise Resource Planning (ERP) systems centralize and streamline core business processes by integrating data across departments, enhancing workflow visibility and coordination. Robotic Process Automation (RPA) automates repetitive, rule-based tasks within existing workflows, increasing efficiency without altering underlying systems. Explore how combining ERP and RPA can optimize workflows and drive digital transformation.

Source and External Links

Enterprise resource planning - ERP is integrated management of core business processes, often in real time using software that collects, stores, and interprets data across departments, enabling seamless flow of information and resource planning to meet future business needs.

What is Enterprise Resource Planning (ERP)? - ERP is business management software designed to manage and automate various organizational functions such as finance, HR, manufacturing, and supply chain by centralizing data in a common database to reduce resource use and data silos.

What is ERP? A Comprehensive Guide - ERP software automates and integrates key business processes across departments, providing detailed analytics, improving visibility, and enabling efficient operations with deployment options including cloud, on-premises, and hybrid models.

dowidth.com

dowidth.com