Condition monitoring utilizes real-time data and sensor technology to detect equipment anomalies, focusing on predictive maintenance and reducing unexpected downtime. Total Productive Maintenance (TPM) engages employees at all levels to optimize equipment efficiency through scheduled preventive tasks and continuous improvement practices. Explore how integrating these strategies can enhance manufacturing productivity and asset longevity.

Why it is important

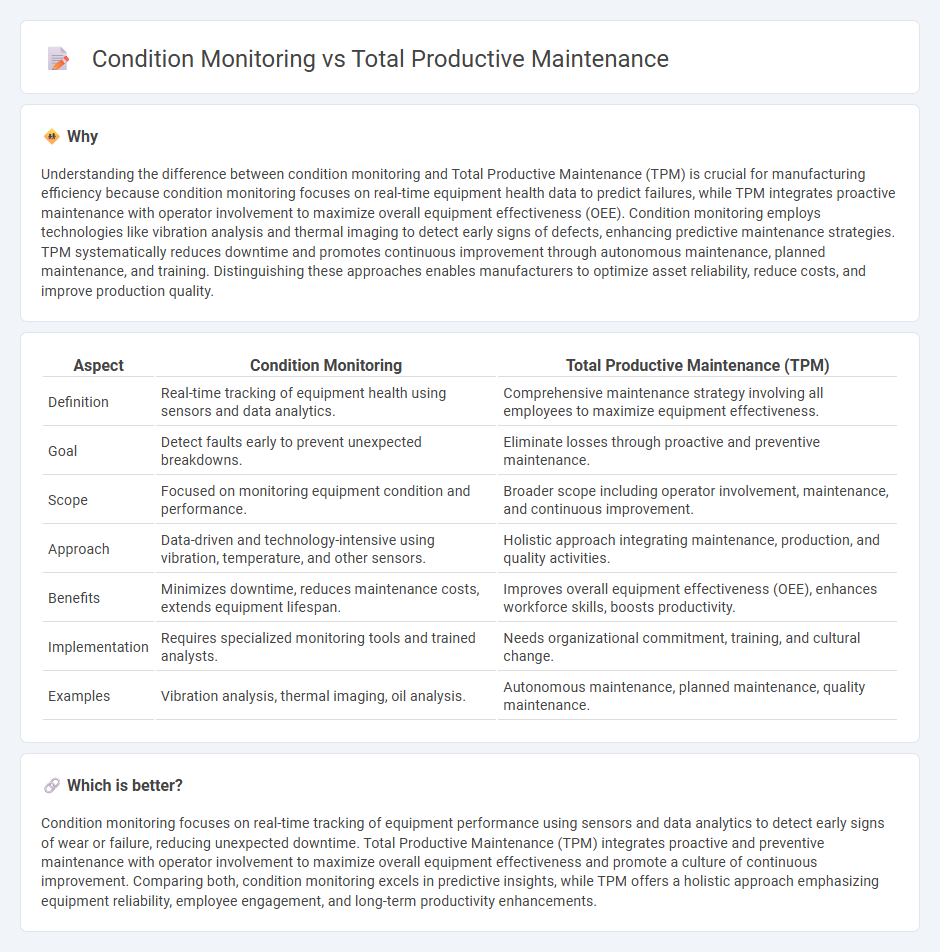

Understanding the difference between condition monitoring and Total Productive Maintenance (TPM) is crucial for manufacturing efficiency because condition monitoring focuses on real-time equipment health data to predict failures, while TPM integrates proactive maintenance with operator involvement to maximize overall equipment effectiveness (OEE). Condition monitoring employs technologies like vibration analysis and thermal imaging to detect early signs of defects, enhancing predictive maintenance strategies. TPM systematically reduces downtime and promotes continuous improvement through autonomous maintenance, planned maintenance, and training. Distinguishing these approaches enables manufacturers to optimize asset reliability, reduce costs, and improve production quality.

Comparison Table

| Aspect | Condition Monitoring | Total Productive Maintenance (TPM) |

|---|---|---|

| Definition | Real-time tracking of equipment health using sensors and data analytics. | Comprehensive maintenance strategy involving all employees to maximize equipment effectiveness. |

| Goal | Detect faults early to prevent unexpected breakdowns. | Eliminate losses through proactive and preventive maintenance. |

| Scope | Focused on monitoring equipment condition and performance. | Broader scope including operator involvement, maintenance, and continuous improvement. |

| Approach | Data-driven and technology-intensive using vibration, temperature, and other sensors. | Holistic approach integrating maintenance, production, and quality activities. |

| Benefits | Minimizes downtime, reduces maintenance costs, extends equipment lifespan. | Improves overall equipment effectiveness (OEE), enhances workforce skills, boosts productivity. |

| Implementation | Requires specialized monitoring tools and trained analysts. | Needs organizational commitment, training, and cultural change. |

| Examples | Vibration analysis, thermal imaging, oil analysis. | Autonomous maintenance, planned maintenance, quality maintenance. |

Which is better?

Condition monitoring focuses on real-time tracking of equipment performance using sensors and data analytics to detect early signs of wear or failure, reducing unexpected downtime. Total Productive Maintenance (TPM) integrates proactive and preventive maintenance with operator involvement to maximize overall equipment effectiveness and promote a culture of continuous improvement. Comparing both, condition monitoring excels in predictive insights, while TPM offers a holistic approach emphasizing equipment reliability, employee engagement, and long-term productivity enhancements.

Connection

Condition monitoring provides real-time data on equipment health, enabling early detection of potential failures. Total Productive Maintenance (TPM) uses this data to schedule proactive maintenance activities, minimizing downtime and maximizing equipment efficiency. The integration of condition monitoring within TPM ensures a systematic approach to sustaining optimal manufacturing performance.

Key Terms

**Total Productive Maintenance:**

Total Productive Maintenance (TPM) emphasizes proactive and preventive maintenance to maximize equipment effectiveness by involving all employees in routine maintenance tasks, improving machine reliability, and minimizing downtime. TPM integrates autonomous maintenance, planned maintenance, and continuous improvement strategies to enhance productivity and reduce operational costs. Explore how implementing TPM can transform your maintenance approach and boost overall equipment effectiveness.

Autonomous Maintenance

Total Productive Maintenance (TPM) emphasizes employee-driven Autonomous Maintenance, where operators actively engage in routine equipment upkeep to prevent breakdowns and optimize performance. Condition Monitoring relies on technological tools and sensors to continuously assess machine health, detect anomalies, and predict failures before they occur. Explore deeper insights into how Autonomous Maintenance transforms TPM effectiveness by empowering operators and enhancing equipment reliability.

Planned Maintenance

Total productive maintenance (TPM) emphasizes maximizing equipment efficiency through proactive involvement of all employees in planned maintenance activities such as routine inspections and systematic repairs. Condition monitoring focuses on real-time tracking of machine health using sensors and diagnostic tools to detect anomalies before failures occur. Explore detailed strategies and benefits of integrating TPM and condition monitoring for optimized maintenance planning.

Source and External Links

TPM Meaning: Components, Benefits, & More - UpKeep - Total Productive Maintenance (TPM) is a process aiming to maximize equipment effectiveness by involving all supporting departments, focusing on reducing downtime, waste, and equipment failure to achieve near "perfect production" through preventive, autonomous, and corrective maintenance.

TPM (Total Productive Maintenance) - TPM is a holistic maintenance approach emphasizing proactive and preventative techniques, leveraging the 5S foundation and eight pillars, to empower operators and improve equipment reliability while promoting a safe working environment.

The 8 Pillars of TPM: Total Productive Maintenance - The 8 pillars of TPM include focused improvement, autonomy, and others that sustain zero breakdowns, zero defects, and zero accidents by sharing responsibility and continuous improvement among all teams.

dowidth.com

dowidth.com