Smart factories leverage IoT sensors, AI analytics, and automation to optimize production efficiency and enable real-time decision-making. Computer-integrated manufacturing (CIM) combines CAD, CAM, and robotics within a unified system to streamline design, planning, and manufacturing processes. Explore how these advanced technologies transform the future of industrial production.

Why it is important

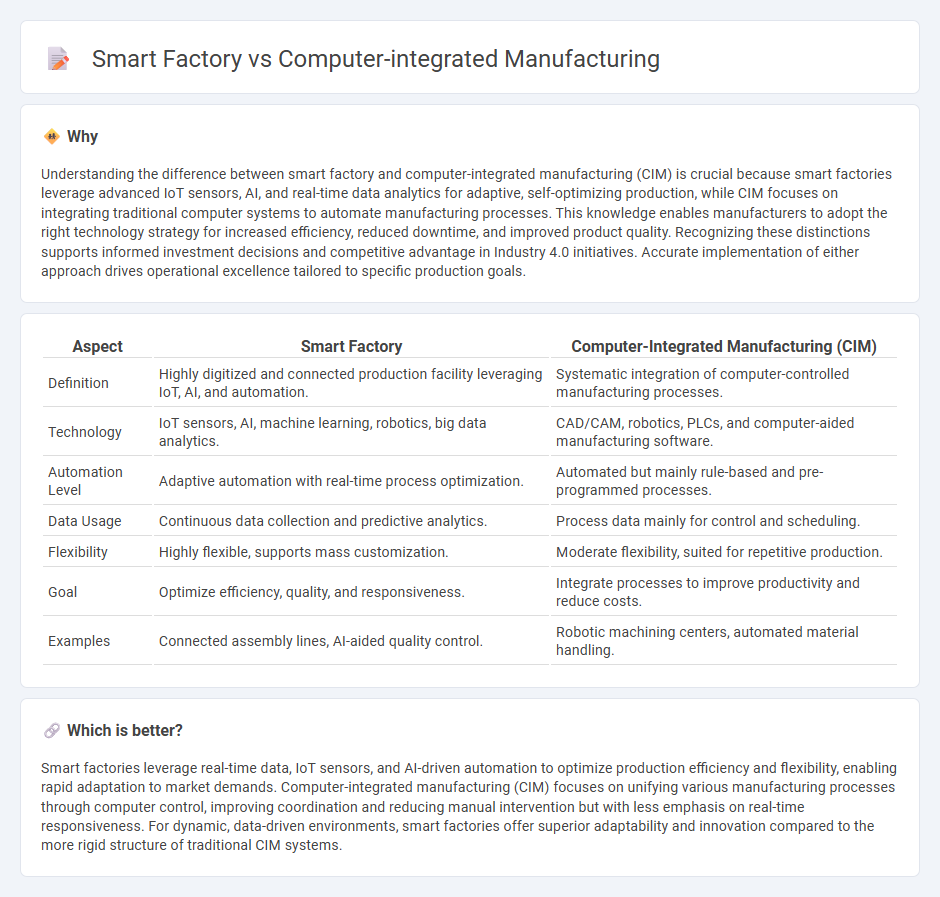

Understanding the difference between smart factory and computer-integrated manufacturing (CIM) is crucial because smart factories leverage advanced IoT sensors, AI, and real-time data analytics for adaptive, self-optimizing production, while CIM focuses on integrating traditional computer systems to automate manufacturing processes. This knowledge enables manufacturers to adopt the right technology strategy for increased efficiency, reduced downtime, and improved product quality. Recognizing these distinctions supports informed investment decisions and competitive advantage in Industry 4.0 initiatives. Accurate implementation of either approach drives operational excellence tailored to specific production goals.

Comparison Table

| Aspect | Smart Factory | Computer-Integrated Manufacturing (CIM) |

|---|---|---|

| Definition | Highly digitized and connected production facility leveraging IoT, AI, and automation. | Systematic integration of computer-controlled manufacturing processes. |

| Technology | IoT sensors, AI, machine learning, robotics, big data analytics. | CAD/CAM, robotics, PLCs, and computer-aided manufacturing software. |

| Automation Level | Adaptive automation with real-time process optimization. | Automated but mainly rule-based and pre-programmed processes. |

| Data Usage | Continuous data collection and predictive analytics. | Process data mainly for control and scheduling. |

| Flexibility | Highly flexible, supports mass customization. | Moderate flexibility, suited for repetitive production. |

| Goal | Optimize efficiency, quality, and responsiveness. | Integrate processes to improve productivity and reduce costs. |

| Examples | Connected assembly lines, AI-aided quality control. | Robotic machining centers, automated material handling. |

Which is better?

Smart factories leverage real-time data, IoT sensors, and AI-driven automation to optimize production efficiency and flexibility, enabling rapid adaptation to market demands. Computer-integrated manufacturing (CIM) focuses on unifying various manufacturing processes through computer control, improving coordination and reducing manual intervention but with less emphasis on real-time responsiveness. For dynamic, data-driven environments, smart factories offer superior adaptability and innovation compared to the more rigid structure of traditional CIM systems.

Connection

Smart factories rely heavily on computer-integrated manufacturing (CIM) systems to automate and optimize production processes, enabling real-time data exchange and seamless coordination between machines, sensors, and control systems. CIM integrates hardware and software technologies such as robotics, IoT devices, and advanced analytics, which form the backbone of smart factory operations that enhance efficiency, flexibility, and scalability. This connectivity facilitates predictive maintenance, reduces downtime, and supports adaptive manufacturing strategies essential for Industry 4.0 environments.

Key Terms

**Computer-Integrated Manufacturing (CIM):**

Computer-Integrated Manufacturing (CIM) integrates computer systems to automate and control the entire production process, enhancing precision and reducing human error. CIM systems unify design, manufacturing, and management operations through advanced software and hardware, improving efficiency and flexibility in manufacturing workflows. Explore more to understand how CIM revolutionizes industrial productivity and drives innovation in automated manufacturing.

Automation

Computer-integrated manufacturing (CIM) automates production processes through centralized control systems combining CAD, CAM, and robotics for seamless workflow. Smart factories utilize advanced automation driven by IoT, AI, and machine learning to enable real-time data exchange, predictive maintenance, and autonomous decision-making. Explore how automation evolves from CIM to smart factories by embracing intelligent technologies transforming industrial efficiency.

CAD/CAM

Computer-integrated manufacturing (CIM) seamlessly combines CAD/CAM systems to enhance design accuracy and automate production processes, resulting in reduced lead times and improved efficiency. Smart factories, however, leverage advanced IoT sensors and AI-driven analytics to create adaptive, real-time manufacturing environments with dynamic CAD/CAM integration that optimizes workflow and predictive maintenance. Explore how CAD/CAM technologies evolve from static designs in CIM to intelligent automation in smart factories for transformative manufacturing outcomes.

Source and External Links

Understanding Computer Integrated Manufacturing (CIM) Meaning - Computer Integrated Manufacturing (CIM) is a holistic, automated approach where computer systems control the entire production process from design (using CAD) through manufacturing (using CAM, CNC machines, and PLCs), streamlining operations for improved efficiency, quality, and output.

Computer-integrated manufacturing - Wikipedia - CIM is the approach of using computers to control all aspects of manufacturing, integrating functions like design, production, and inventory control via real-time information exchange to enhance speed, accuracy, and flexibility in manufacturing.

Computer-Integrated Manufacturing (CIM): Automation & Efficiency - CIM encompasses elements such as product design (CAD), process planning (CAM), production control, quality assurance, inventory management, and maintenance, aiming to automate and integrate manufacturing processes and business functions via computer networks to boost efficiency and competitiveness.

dowidth.com

dowidth.com