Soft robotics offers enhanced flexibility and adaptability by utilizing compliant materials that mimic natural movements, contrasting with rigid automation systems defined by fixed structures and limited range of motion. This innovation improves safety and efficiency in manufacturing processes involving delicate or irregularly shaped items, expanding possibilities beyond the constraints of traditional rigid robotic arms. Discover how integrating soft robotics can revolutionize your manufacturing operations and drive competitive advantage.

Why it is important

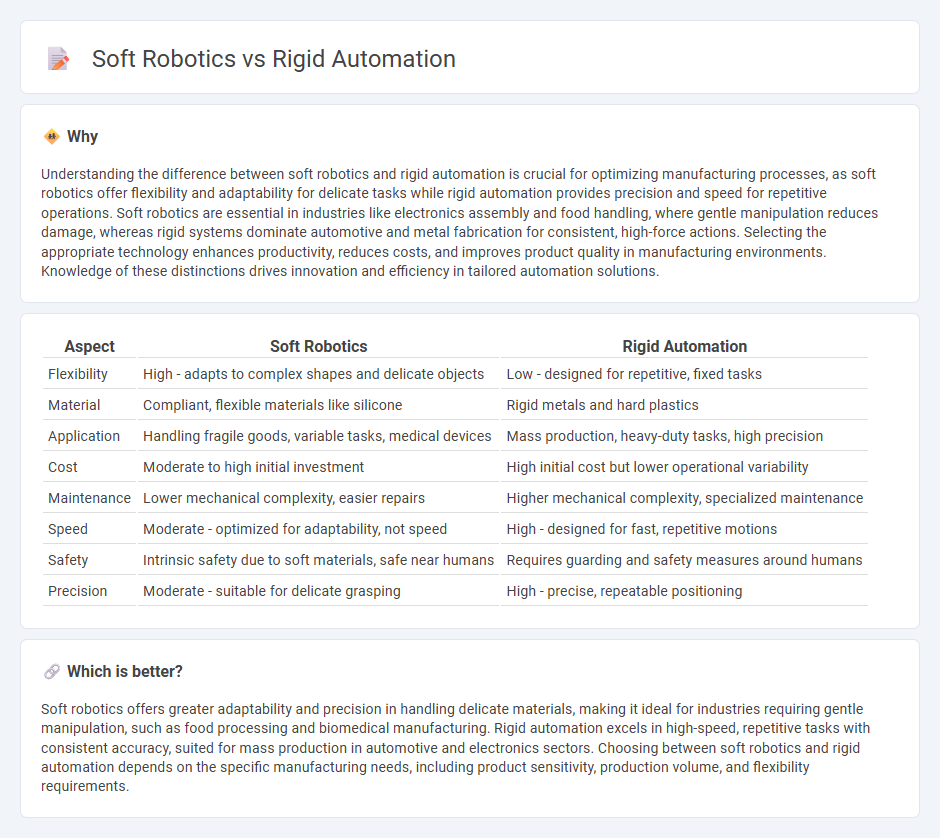

Understanding the difference between soft robotics and rigid automation is crucial for optimizing manufacturing processes, as soft robotics offer flexibility and adaptability for delicate tasks while rigid automation provides precision and speed for repetitive operations. Soft robotics are essential in industries like electronics assembly and food handling, where gentle manipulation reduces damage, whereas rigid systems dominate automotive and metal fabrication for consistent, high-force actions. Selecting the appropriate technology enhances productivity, reduces costs, and improves product quality in manufacturing environments. Knowledge of these distinctions drives innovation and efficiency in tailored automation solutions.

Comparison Table

| Aspect | Soft Robotics | Rigid Automation |

|---|---|---|

| Flexibility | High - adapts to complex shapes and delicate objects | Low - designed for repetitive, fixed tasks |

| Material | Compliant, flexible materials like silicone | Rigid metals and hard plastics |

| Application | Handling fragile goods, variable tasks, medical devices | Mass production, heavy-duty tasks, high precision |

| Cost | Moderate to high initial investment | High initial cost but lower operational variability |

| Maintenance | Lower mechanical complexity, easier repairs | Higher mechanical complexity, specialized maintenance |

| Speed | Moderate - optimized for adaptability, not speed | High - designed for fast, repetitive motions |

| Safety | Intrinsic safety due to soft materials, safe near humans | Requires guarding and safety measures around humans |

| Precision | Moderate - suitable for delicate grasping | High - precise, repeatable positioning |

Which is better?

Soft robotics offers greater adaptability and precision in handling delicate materials, making it ideal for industries requiring gentle manipulation, such as food processing and biomedical manufacturing. Rigid automation excels in high-speed, repetitive tasks with consistent accuracy, suited for mass production in automotive and electronics sectors. Choosing between soft robotics and rigid automation depends on the specific manufacturing needs, including product sensitivity, production volume, and flexibility requirements.

Connection

Soft robotics integrates flexible materials and sensors to enhance adaptability and precision in manufacturing processes, complementing rigid automation systems that provide high-speed and consistent performance. The synergy between soft robotics and rigid automation enables complex tasks such as delicate material handling and assembly in industries like electronics and automotive manufacturing. Combining these technologies optimizes efficiency, reduces downtime, and improves product quality by leveraging the strengths of both adaptability and rigidity.

Key Terms

Flexibility

Rigid automation systems excel in high-speed, repetitive tasks with consistent precision but lack adaptability to diverse product variations. Soft robotics offers enhanced flexibility through compliant materials and adaptive control, enabling safe interaction with delicate objects and complex environments. Explore the advancements in robotic flexibility to understand how soft robotics is transforming automation.

Customization

Rigid automation offers high precision and efficiency for repetitive tasks but lacks adaptability in customization, making it suitable for large-scale production with minimal variation. Soft robotics provides enhanced flexibility and sensitivity, allowing tailored solutions for intricate, variable applications, especially in healthcare and delicate manufacturing. Explore how integrating soft robotics can revolutionize personalized automation strategies.

Throughput

Rigid automation excels in high-throughput industrial settings due to its precise, repetitive motion and ability to operate continuously with minimal downtime. Soft robotics emphasizes adaptability and safe human interaction, often trading off throughput for flexibility in tasks involving delicate handling. Explore how each technology impacts production efficiency and explore suitable applications for optimized manufacturing throughput.

Source and External Links

Automation - Rigid Industrial Group - Rigid Industrial Group provides automation services across various sectors including oil and gas, industrial, food and beverage, government contracts, and water/wastewater.

Rigid Automation Information - Rigid Automation is an electrical equipment manufacturing company based in Norman, Oklahoma with around 15 employees.

Rigid Industrial Group - This group focuses on delivering safe, reliable, and affordable electrical controls and automation services with a commitment to quality workmanship and customer service.

dowidth.com

dowidth.com