Industrial metaverse integrates virtual reality, AI, and IoT to create immersive digital twins for real-time manufacturing simulation and optimization. Digital Thread links data across the product lifecycle, enhancing traceability, collaboration, and decision-making through continuous data flow from design to production. Explore how these transformative technologies reshape modern manufacturing processes.

Why it is important

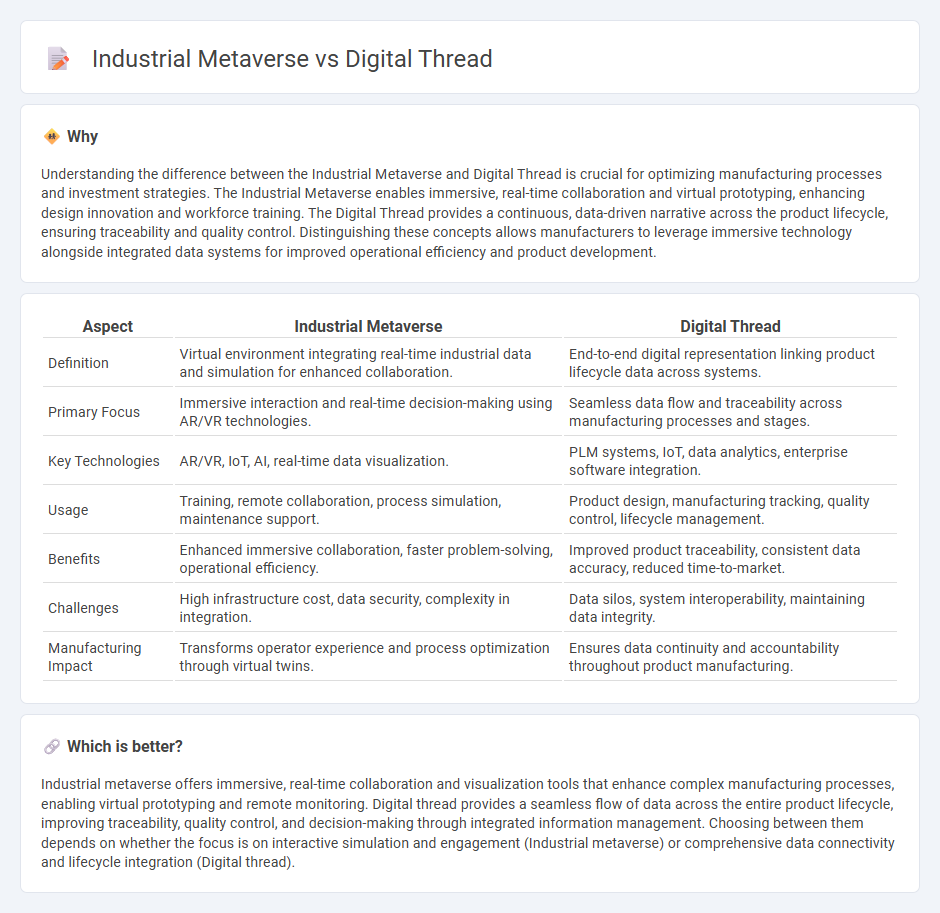

Understanding the difference between the Industrial Metaverse and Digital Thread is crucial for optimizing manufacturing processes and investment strategies. The Industrial Metaverse enables immersive, real-time collaboration and virtual prototyping, enhancing design innovation and workforce training. The Digital Thread provides a continuous, data-driven narrative across the product lifecycle, ensuring traceability and quality control. Distinguishing these concepts allows manufacturers to leverage immersive technology alongside integrated data systems for improved operational efficiency and product development.

Comparison Table

| Aspect | Industrial Metaverse | Digital Thread |

|---|---|---|

| Definition | Virtual environment integrating real-time industrial data and simulation for enhanced collaboration. | End-to-end digital representation linking product lifecycle data across systems. |

| Primary Focus | Immersive interaction and real-time decision-making using AR/VR technologies. | Seamless data flow and traceability across manufacturing processes and stages. |

| Key Technologies | AR/VR, IoT, AI, real-time data visualization. | PLM systems, IoT, data analytics, enterprise software integration. |

| Usage | Training, remote collaboration, process simulation, maintenance support. | Product design, manufacturing tracking, quality control, lifecycle management. |

| Benefits | Enhanced immersive collaboration, faster problem-solving, operational efficiency. | Improved product traceability, consistent data accuracy, reduced time-to-market. |

| Challenges | High infrastructure cost, data security, complexity in integration. | Data silos, system interoperability, maintaining data integrity. |

| Manufacturing Impact | Transforms operator experience and process optimization through virtual twins. | Ensures data continuity and accountability throughout product manufacturing. |

Which is better?

Industrial metaverse offers immersive, real-time collaboration and visualization tools that enhance complex manufacturing processes, enabling virtual prototyping and remote monitoring. Digital thread provides a seamless flow of data across the entire product lifecycle, improving traceability, quality control, and decision-making through integrated information management. Choosing between them depends on whether the focus is on interactive simulation and engagement (Industrial metaverse) or comprehensive data connectivity and lifecycle integration (Digital thread).

Connection

The Industrial Metaverse integrates digital thread technology to create a continuous, real-time data flow throughout the manufacturing lifecycle, enhancing product design, production, and maintenance processes. Digital threads enable seamless data interoperability between physical assets and virtual models within the Industrial Metaverse, driving improved collaboration, predictive analytics, and operational efficiency. This connection facilitates smart manufacturing by linking supply chain management, equipment monitoring, and workforce training in a unified, immersive virtual environment.

Key Terms

Data Connectivity

Digital Thread and Industrial Metaverse both emphasize data connectivity but differ in scope and application; Digital Thread ensures seamless data flow across product lifecycle stages for enhanced traceability and decision-making, while Industrial Metaverse integrates real-time data into immersive virtual environments for simulation and training. Effective data connectivity in Digital Thread relies on IoT, cloud computing, and AI to link physical and digital assets, whereas Industrial Metaverse leverages augmented reality (AR), digital twins, and 5G to create interconnected, interactive industrial ecosystems. Explore how these technologies transform manufacturing processes and elevate operational efficiency through unified data connectivity.

Virtual Twin

The Digital Thread integrates real-time data flow across the product lifecycle, enabling continuous synchronization between physical assets and their Virtual Twins for enhanced operational efficiency. The Industrial Metaverse extends this concept by creating immersive, interactive virtual environments that simulate entire industrial ecosystems, allowing for advanced collaboration and scenario testing using Virtual Twins. Discover how leveraging Virtual Twins within these frameworks can revolutionize manufacturing and asset management strategies.

Real-time Collaboration

Digital Thread enables seamless real-time collaboration by providing a continuous flow of accurate product data across design, manufacturing, and service stages, enhancing decision-making and reducing errors. The Industrial Metaverse integrates immersive technologies with IoT and AI to create interactive virtual environments, allowing stakeholders to collaborate in real-time on complex industrial processes and simulations. Explore how these technologies shape the future of industrial collaboration and operational efficiency.

Source and External Links

Digital thread - Wikipedia - A data-driven architecture that links information generated across the entire product lifecycle, enabling real-time decision making and seamless data access by integrating data from all stages, systems, and supply chains.

Definition of Digital Thread - Digital Twin Consortium - A bidirectional, interconnected information system that securely links multiple dimensions--including structure, behavior, time, and lifecycle stages--to foster seamless, trustworthy data flow and informed decision-making throughout a product's or system's existence.

A digital thread What it is and why you need it - AVEVA - The continuous digital flow of data and information chained between connected systems, devices, or people, ensuring everyone in the organization accesses reliable, accurate, and timely information for confident decision-making.

dowidth.com

dowidth.com