Hyperautomation integrates advanced technologies such as AI, machine learning, and robotic process automation to streamline manufacturing workflows and enhance operational efficiency. Manufacturing Execution Systems (MES) focus on real-time monitoring, control, and management of production processes to improve quality and reduce downtime. Discover how combining hyperautomation and MES can revolutionize your manufacturing operations.

Why it is important

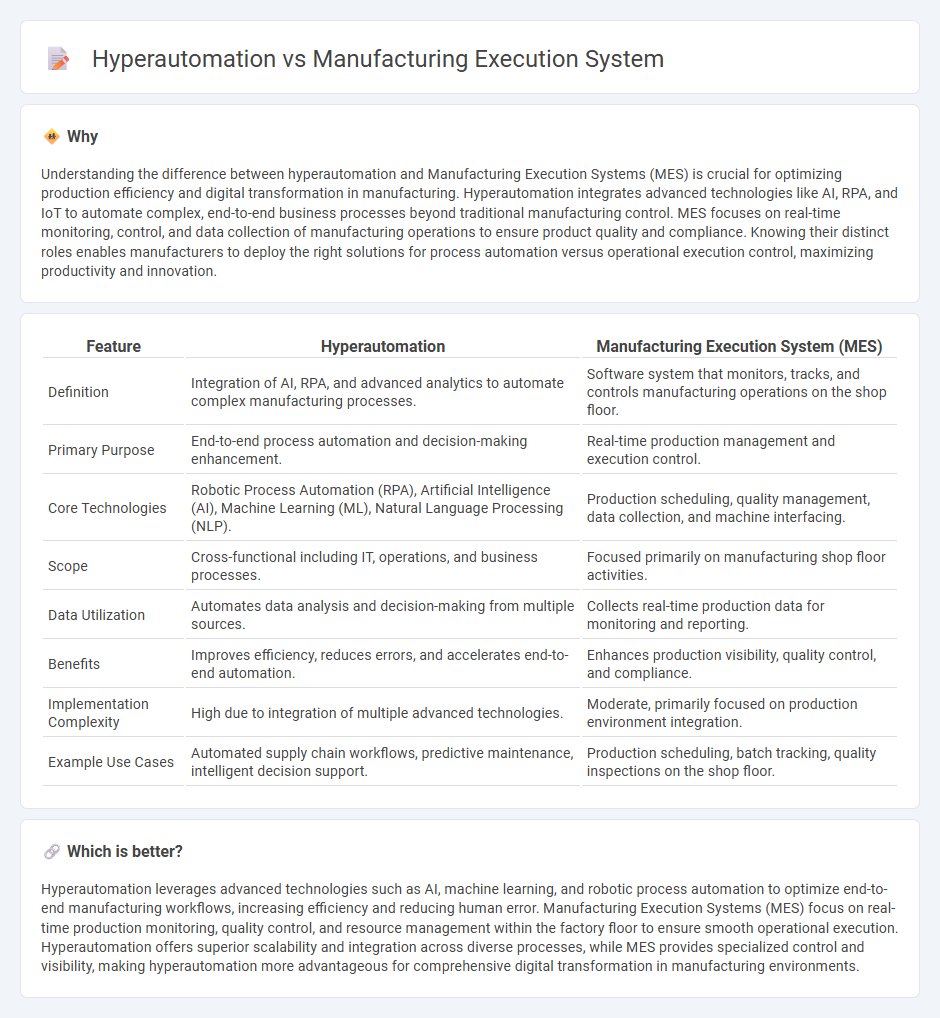

Understanding the difference between hyperautomation and Manufacturing Execution Systems (MES) is crucial for optimizing production efficiency and digital transformation in manufacturing. Hyperautomation integrates advanced technologies like AI, RPA, and IoT to automate complex, end-to-end business processes beyond traditional manufacturing control. MES focuses on real-time monitoring, control, and data collection of manufacturing operations to ensure product quality and compliance. Knowing their distinct roles enables manufacturers to deploy the right solutions for process automation versus operational execution control, maximizing productivity and innovation.

Comparison Table

| Feature | Hyperautomation | Manufacturing Execution System (MES) |

|---|---|---|

| Definition | Integration of AI, RPA, and advanced analytics to automate complex manufacturing processes. | Software system that monitors, tracks, and controls manufacturing operations on the shop floor. |

| Primary Purpose | End-to-end process automation and decision-making enhancement. | Real-time production management and execution control. |

| Core Technologies | Robotic Process Automation (RPA), Artificial Intelligence (AI), Machine Learning (ML), Natural Language Processing (NLP). | Production scheduling, quality management, data collection, and machine interfacing. |

| Scope | Cross-functional including IT, operations, and business processes. | Focused primarily on manufacturing shop floor activities. |

| Data Utilization | Automates data analysis and decision-making from multiple sources. | Collects real-time production data for monitoring and reporting. |

| Benefits | Improves efficiency, reduces errors, and accelerates end-to-end automation. | Enhances production visibility, quality control, and compliance. |

| Implementation Complexity | High due to integration of multiple advanced technologies. | Moderate, primarily focused on production environment integration. |

| Example Use Cases | Automated supply chain workflows, predictive maintenance, intelligent decision support. | Production scheduling, batch tracking, quality inspections on the shop floor. |

Which is better?

Hyperautomation leverages advanced technologies such as AI, machine learning, and robotic process automation to optimize end-to-end manufacturing workflows, increasing efficiency and reducing human error. Manufacturing Execution Systems (MES) focus on real-time production monitoring, quality control, and resource management within the factory floor to ensure smooth operational execution. Hyperautomation offers superior scalability and integration across diverse processes, while MES provides specialized control and visibility, making hyperautomation more advantageous for comprehensive digital transformation in manufacturing environments.

Connection

Hyperautomation enhances Manufacturing Execution Systems (MES) by integrating advanced technologies like AI, machine learning, and robotic process automation to streamline production workflows and improve real-time decision-making. MES captures live data from shop floor equipment, which hyperautomation analyzes to optimize operations, reduce downtime, and increase efficiency. This synergy accelerates digital transformation in manufacturing, driving higher productivity and quality standards.

Key Terms

**Manufacturing Execution System (MES):**

Manufacturing Execution System (MES) is a critical software solution designed to optimize and monitor real-time production processes, ensuring enhanced operational efficiency, quality control, and compliance with industry standards. MES integrates with enterprise resource planning (ERP) systems and IoT devices to provide detailed insights into shop floor activities, reducing downtime and improving traceability. Explore how MES can transform your manufacturing operations and drive productivity improvements.

Real-time Production Monitoring

Manufacturing Execution Systems (MES) provide real-time production monitoring by tracking work-in-progress, machine status, and quality metrics on the shop floor, ensuring timely data for operational decision-making. Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to enhance real-time monitoring with predictive analytics and automated responses, driving higher efficiency and reduced downtime. Explore the differences and benefits of MES and hyperautomation in production monitoring to optimize manufacturing operations effectively.

Work Order Management

Manufacturing Execution Systems (MES) offer real-time tracking and control of work orders on the shop floor, ensuring precise scheduling, resource allocation, and status updates. Hyperautomation integrates MES with AI, machine learning, and robotic process automation to enhance work order management by automating data capture, predictive maintenance, and workflow optimization. Explore how combining MES and hyperautomation revolutionizes work order efficiency and operational excellence.

Source and External Links

Manufacturing execution system - Wikipedia - MES are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods in real time, enabling control and optimization of production processes, resources, and quality across the plant floor.

What is a Manufacturing Execution System (MES)? - IBM - MES is a software-based solution that monitors and controls production processes on the shop floor, providing real-time visibility, optimizing scheduling and resource allocation, and supporting quality assurance and compliance.

Manufacturing execution system software - MES software manages, monitors, and controls production processes in real time across plants, aligning with smart manufacturing principles for flexible, sustainable, and informed production operations.

dowidth.com

dowidth.com