Robotic Process Automation (RPA) enhances manufacturing efficiency by automating repetitive tasks using software robots, reducing human error and operational costs. Flexible Manufacturing Systems (FMS) utilize programmable machinery and robotics to adapt quickly to product changes and varying production volumes, increasing agility and customization capabilities. Explore the benefits and applications of RPA and FMS to optimize modern manufacturing processes.

Why it is important

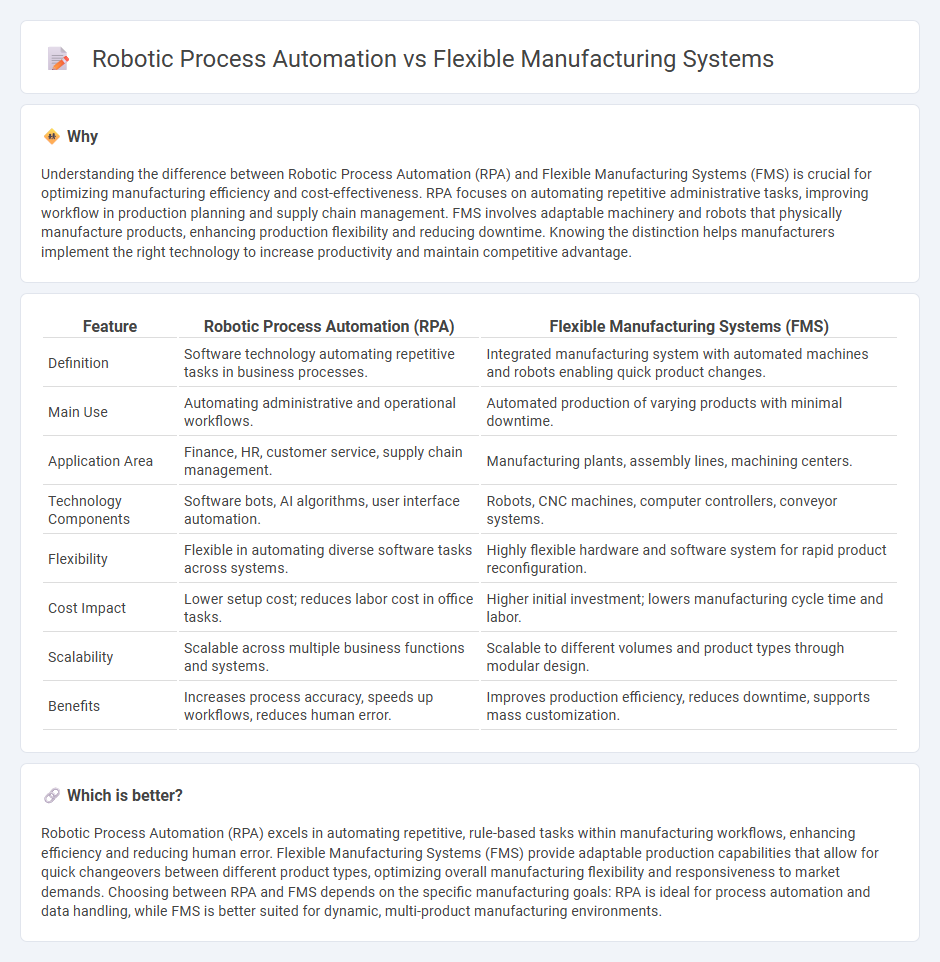

Understanding the difference between Robotic Process Automation (RPA) and Flexible Manufacturing Systems (FMS) is crucial for optimizing manufacturing efficiency and cost-effectiveness. RPA focuses on automating repetitive administrative tasks, improving workflow in production planning and supply chain management. FMS involves adaptable machinery and robots that physically manufacture products, enhancing production flexibility and reducing downtime. Knowing the distinction helps manufacturers implement the right technology to increase productivity and maintain competitive advantage.

Comparison Table

| Feature | Robotic Process Automation (RPA) | Flexible Manufacturing Systems (FMS) |

|---|---|---|

| Definition | Software technology automating repetitive tasks in business processes. | Integrated manufacturing system with automated machines and robots enabling quick product changes. |

| Main Use | Automating administrative and operational workflows. | Automated production of varying products with minimal downtime. |

| Application Area | Finance, HR, customer service, supply chain management. | Manufacturing plants, assembly lines, machining centers. |

| Technology Components | Software bots, AI algorithms, user interface automation. | Robots, CNC machines, computer controllers, conveyor systems. |

| Flexibility | Flexible in automating diverse software tasks across systems. | Highly flexible hardware and software system for rapid product reconfiguration. |

| Cost Impact | Lower setup cost; reduces labor cost in office tasks. | Higher initial investment; lowers manufacturing cycle time and labor. |

| Scalability | Scalable across multiple business functions and systems. | Scalable to different volumes and product types through modular design. |

| Benefits | Increases process accuracy, speeds up workflows, reduces human error. | Improves production efficiency, reduces downtime, supports mass customization. |

Which is better?

Robotic Process Automation (RPA) excels in automating repetitive, rule-based tasks within manufacturing workflows, enhancing efficiency and reducing human error. Flexible Manufacturing Systems (FMS) provide adaptable production capabilities that allow for quick changeovers between different product types, optimizing overall manufacturing flexibility and responsiveness to market demands. Choosing between RPA and FMS depends on the specific manufacturing goals: RPA is ideal for process automation and data handling, while FMS is better suited for dynamic, multi-product manufacturing environments.

Connection

Robotic Process Automation (RPA) enhances Flexible Manufacturing Systems (FMS) by streamlining repetitive tasks and enabling real-time data integration for adaptive production. RPA facilitates seamless communication between machines and software, optimizing workflow efficiency and reducing downtime in FMS environments. This integration accelerates decision-making processes and supports customization in manufacturing operations.

Key Terms

Adaptability

Flexible manufacturing systems (FMS) excel in adaptability by enabling quick reconfiguration of machinery and workflows to accommodate varying product designs and production volumes, enhancing efficiency in complex manufacturing environments. Robotic process automation (RPA) focuses on adaptability through software bots that adjust to diverse digital tasks, improving workflow automation and reducing human error in repetitive processes. Explore in-depth comparisons to understand how each technology drives adaptability in modern industries.

Automation

Flexible manufacturing systems (FMS) integrate automated machines and computer-controlled workstations to enhance production flexibility and efficiency, enabling rapid adaptation to varying product designs. Robotic process automation (RPA) focuses on automating repetitive, rule-based digital tasks by deploying software robots to improve accuracy and reduce human intervention in administrative processes. Explore the distinct applications and benefits of FMS and RPA to optimize automation strategies in your industry.

Integration

Flexible manufacturing systems (FMS) enable seamless integration of machines, tools, and material handling systems to optimize production workflows with high adaptability and scalability. Robotic process automation (RPA) focuses on the software-driven integration of repetitive business processes, enhancing efficiency through digitization and real-time data processing. Explore how combining FMS and RPA integration strategies can revolutionize operational performance and drive smart manufacturing innovation.

Source and External Links

Flexible manufacturing system - Wikipedia - A flexible manufacturing system (FMS) is designed with routing and machine flexibility to adapt production to changes, featuring automated CNC machines, material handling systems, and central control for optimized manufacturing flow and efficiency.

How Flexible Manufacturing System (FMS) is Changing Production - FMS integrates computer control with automated material handling to create a responsive production ecosystem that adjusts production parameters and routes in real time, leveraging feedback loops for continuous process optimization.

Flexible Manufacturing Systems (FMS) - Autodesk - FMS offers routing and machine flexibility, allowing production sequence rearrangement and machine interchangeability, with types including dedicated, sequential, engineered, random, and modular FMS adaptable to various industry needs.

dowidth.com

dowidth.com