Closed-loop manufacturing integrates real-time feedback systems to continuously optimize production processes, reducing waste and improving product quality. Mass customization tailors products to individual customer preferences while maintaining the efficiency of mass production, leveraging modular design and flexible manufacturing technologies. Explore how these innovative approaches redefine efficiency and personalization in modern manufacturing.

Why it is important

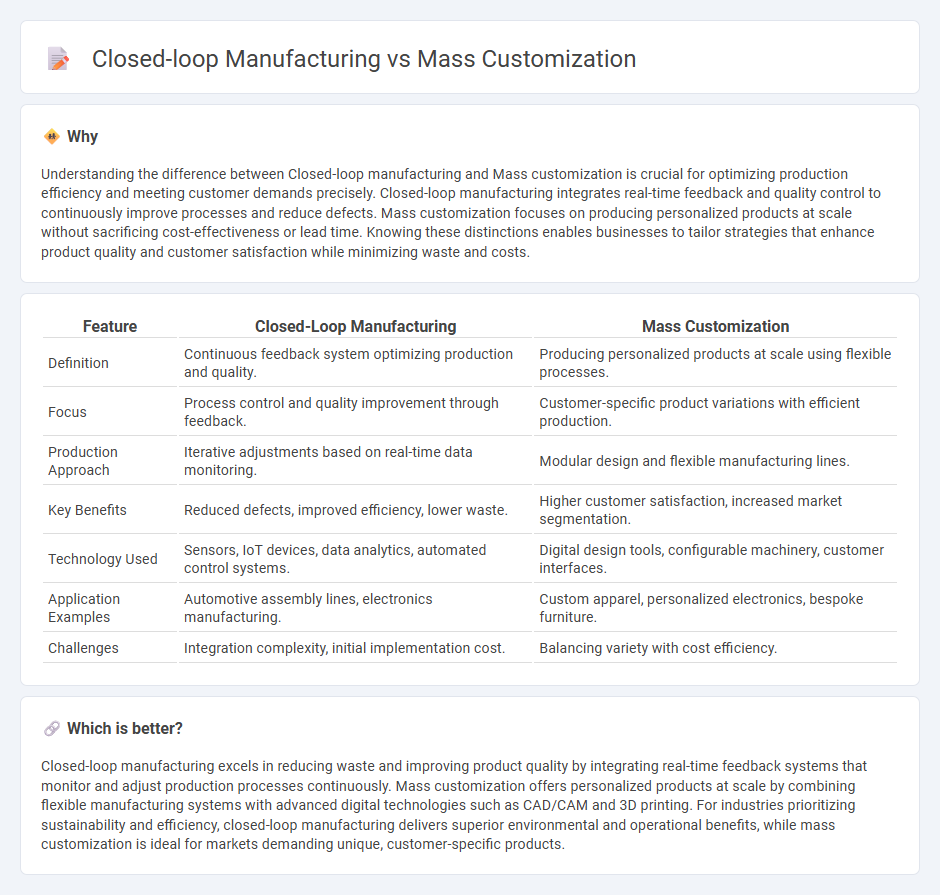

Understanding the difference between Closed-loop manufacturing and Mass customization is crucial for optimizing production efficiency and meeting customer demands precisely. Closed-loop manufacturing integrates real-time feedback and quality control to continuously improve processes and reduce defects. Mass customization focuses on producing personalized products at scale without sacrificing cost-effectiveness or lead time. Knowing these distinctions enables businesses to tailor strategies that enhance product quality and customer satisfaction while minimizing waste and costs.

Comparison Table

| Feature | Closed-Loop Manufacturing | Mass Customization |

|---|---|---|

| Definition | Continuous feedback system optimizing production and quality. | Producing personalized products at scale using flexible processes. |

| Focus | Process control and quality improvement through feedback. | Customer-specific product variations with efficient production. |

| Production Approach | Iterative adjustments based on real-time data monitoring. | Modular design and flexible manufacturing lines. |

| Key Benefits | Reduced defects, improved efficiency, lower waste. | Higher customer satisfaction, increased market segmentation. |

| Technology Used | Sensors, IoT devices, data analytics, automated control systems. | Digital design tools, configurable machinery, customer interfaces. |

| Application Examples | Automotive assembly lines, electronics manufacturing. | Custom apparel, personalized electronics, bespoke furniture. |

| Challenges | Integration complexity, initial implementation cost. | Balancing variety with cost efficiency. |

Which is better?

Closed-loop manufacturing excels in reducing waste and improving product quality by integrating real-time feedback systems that monitor and adjust production processes continuously. Mass customization offers personalized products at scale by combining flexible manufacturing systems with advanced digital technologies such as CAD/CAM and 3D printing. For industries prioritizing sustainability and efficiency, closed-loop manufacturing delivers superior environmental and operational benefits, while mass customization is ideal for markets demanding unique, customer-specific products.

Connection

Closed-loop manufacturing integrates real-time feedback and data analytics to continuously optimize production processes, closely aligning with mass customization goals by enabling flexible, efficient adaptation to individual customer specifications. This interconnected approach reduces waste, improves product quality, and accelerates response times, meeting diverse market demands without sacrificing scalability. Implementing closed-loop systems facilitates precise control over customized manufacturing workflows, ensuring consistent delivery of personalized products.

Key Terms

Personalization

Mass customization enables personalized products by combining flexible processes with customer-specific inputs, enhancing consumer satisfaction through tailored solutions. Closed-loop manufacturing optimizes personalization by integrating real-time feedback and iterative adjustments, ensuring precise customization and reduced waste. Explore how these manufacturing strategies revolutionize personalization in modern production.

Feedback systems

Mass customization leverages real-time feedback systems to tailor products to individual customer preferences efficiently, enhancing personalization without sacrificing scale. Closed-loop manufacturing integrates comprehensive feedback loops across production processes to continuously optimize quality, reduce waste, and improve resource efficiency. Explore how advanced feedback systems transform manufacturing by bridging customization and sustainability for deeper insights.

Flexibility

Mass customization delivers high flexibility by allowing tailored products to meet individual customer preferences through modular designs and adaptable production processes. Closed-loop manufacturing enhances flexibility by integrating real-time feedback and recycling materials, enabling dynamic adjustments to reduce waste and improve product quality. Explore how these flexible manufacturing strategies can transform your production efficiency and customer satisfaction.

Source and External Links

Guide to Mass Customization - Formlabs - Mass customization combines personalized product flexibility with low-cost production, and includes key types like collaborative and adaptive customization exemplified by Nike by You.

Mass Customization: A Complete Guide - Deskera - Mass customization is a business strategy that delivers personalized products cost-effectively by understanding customer needs, leveraging technology, scalability, and automation.

Mass customization - Wikipedia - Mass customization uses flexible production systems to achieve the mass production of individually customized goods, balancing cost, delivery, and quality through modular and collaborative design approaches.

dowidth.com

dowidth.com