Automated guided vehicles (AGVs) provide flexible, programmable material transport with advanced navigation and safety features, enhancing efficiency in dynamic manufacturing environments. Pallet shuttle systems optimize high-density pallet storage and retrieval in warehouses, maximizing space utilization and reducing manual labor with automated shuttle carts. Explore the differences in automation solutions to determine the best fit for your production workflow.

Why it is important

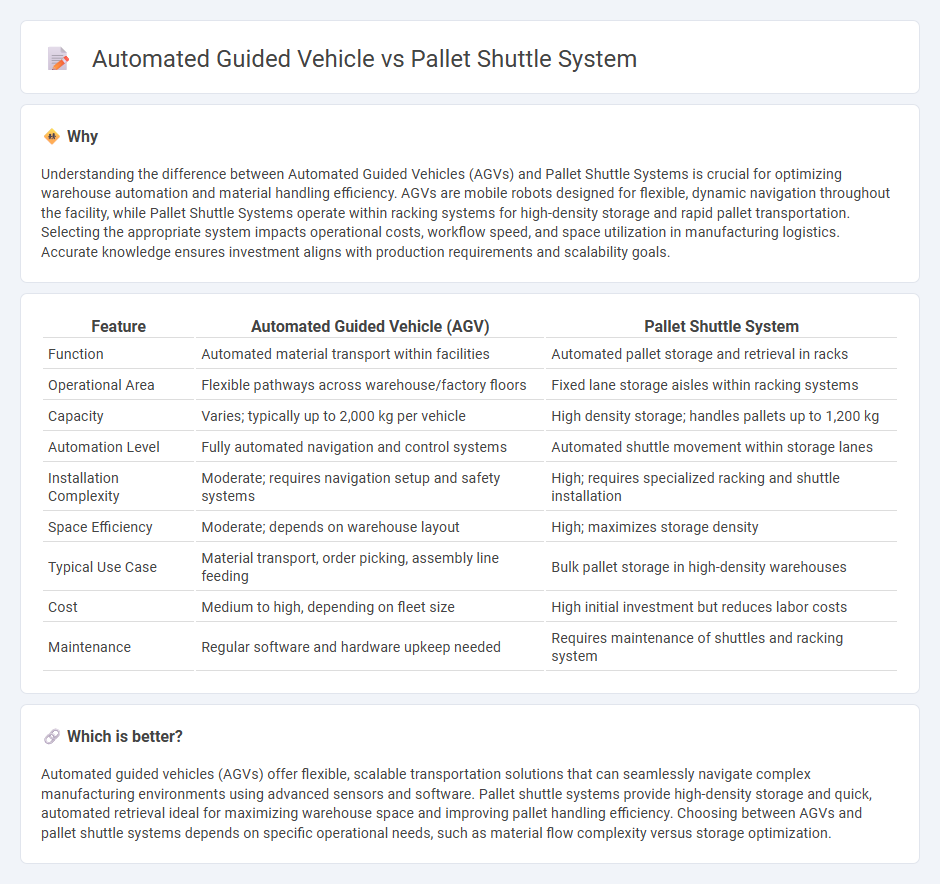

Understanding the difference between Automated Guided Vehicles (AGVs) and Pallet Shuttle Systems is crucial for optimizing warehouse automation and material handling efficiency. AGVs are mobile robots designed for flexible, dynamic navigation throughout the facility, while Pallet Shuttle Systems operate within racking systems for high-density storage and rapid pallet transportation. Selecting the appropriate system impacts operational costs, workflow speed, and space utilization in manufacturing logistics. Accurate knowledge ensures investment aligns with production requirements and scalability goals.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Pallet Shuttle System |

|---|---|---|

| Function | Automated material transport within facilities | Automated pallet storage and retrieval in racks |

| Operational Area | Flexible pathways across warehouse/factory floors | Fixed lane storage aisles within racking systems |

| Capacity | Varies; typically up to 2,000 kg per vehicle | High density storage; handles pallets up to 1,200 kg |

| Automation Level | Fully automated navigation and control systems | Automated shuttle movement within storage lanes |

| Installation Complexity | Moderate; requires navigation setup and safety systems | High; requires specialized racking and shuttle installation |

| Space Efficiency | Moderate; depends on warehouse layout | High; maximizes storage density |

| Typical Use Case | Material transport, order picking, assembly line feeding | Bulk pallet storage in high-density warehouses |

| Cost | Medium to high, depending on fleet size | High initial investment but reduces labor costs |

| Maintenance | Regular software and hardware upkeep needed | Requires maintenance of shuttles and racking system |

Which is better?

Automated guided vehicles (AGVs) offer flexible, scalable transportation solutions that can seamlessly navigate complex manufacturing environments using advanced sensors and software. Pallet shuttle systems provide high-density storage and quick, automated retrieval ideal for maximizing warehouse space and improving pallet handling efficiency. Choosing between AGVs and pallet shuttle systems depends on specific operational needs, such as material flow complexity versus storage optimization.

Connection

Automated Guided Vehicles (AGVs) and Pallet Shuttle Systems synergize in manufacturing by streamlining material handling and storage. AGVs autonomously transport pallets to and from the Pallet Shuttle, which efficiently stores and retrieves pallets within high-density racking systems. This integration enhances operational efficiency, reduces labor costs, and optimizes warehouse space utilization in modern manufacturing environments.

Key Terms

Storage Density

Pallet shuttle systems significantly enhance storage density by utilizing deep lane storage and maximizing cube utilization within racking structures, compared to automated guided vehicles (AGVs) that typically require wider aisles for navigation. The shuttle's ability to operate within narrow aisles increases pallet storage capacity up to 60% more than AGV-based systems. Explore how pallet shuttle solutions can transform your warehouse storage efficiency.

Flexibility

Pallet shuttle systems offer high-density storage with fixed rail tracks, optimizing space but limiting aisle access and system flexibility. Automated guided vehicles (AGVs) provide greater operational flexibility by navigating dynamic warehouse layouts and adapting to various tasks without fixed infrastructure. Discover more to determine which system best suits your warehouse flexibility needs.

Throughput

Pallet shuttle systems offer significantly higher throughput by enabling dense storage and rapid, automated retrieval of pallets within racking, reducing travel time compared to automated guided vehicles (AGVs) which navigate aisles individually. Shuttle systems maximize space utilization and increase picking speed, particularly in high-volume warehouse operations with repetitive, palletized inventory handling. Explore detailed comparisons to optimize your warehouse throughput and automation strategy.

Source and External Links

Pallet Shuttle Racking System - Mecalux.com - The Pallet Shuttle is a semi-automated, high-density storage system where an electric shuttle car moves pallets along rails within storage channels, controlled by an operator using a tablet, and does not require the forklift to enter the racking.

Shuttle Pallet Racking | AR Racking Inc - Pallet Shuttle Racking is a compact, semi-automated solution that uses self-powered shuttle carts to automatically store and retrieve pallets within the rack, supporting both FIFO and LIFO stock management and enabling high-density, efficient warehouse operations.

Pallet Shuttle System - Big Joe Handling Systems - The Pallet Shuttle system is a high-density storage solution where an electric shuttle runs inside storage channels, depositing pallets in the first available location, reducing operating times, increasing storage depth, and minimizing rack damage by eliminating forklift traffic in the lanes.

dowidth.com

dowidth.com